Planar magnetron sputtering cathode capable of improving target material utilization rate

A technology of magnetron sputtering and utilization rate, which is applied in the direction of sputtering coating, metal material coating process, ion implantation plating, etc., can solve the problem of high cost of target material, and achieve the effect of improving target material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

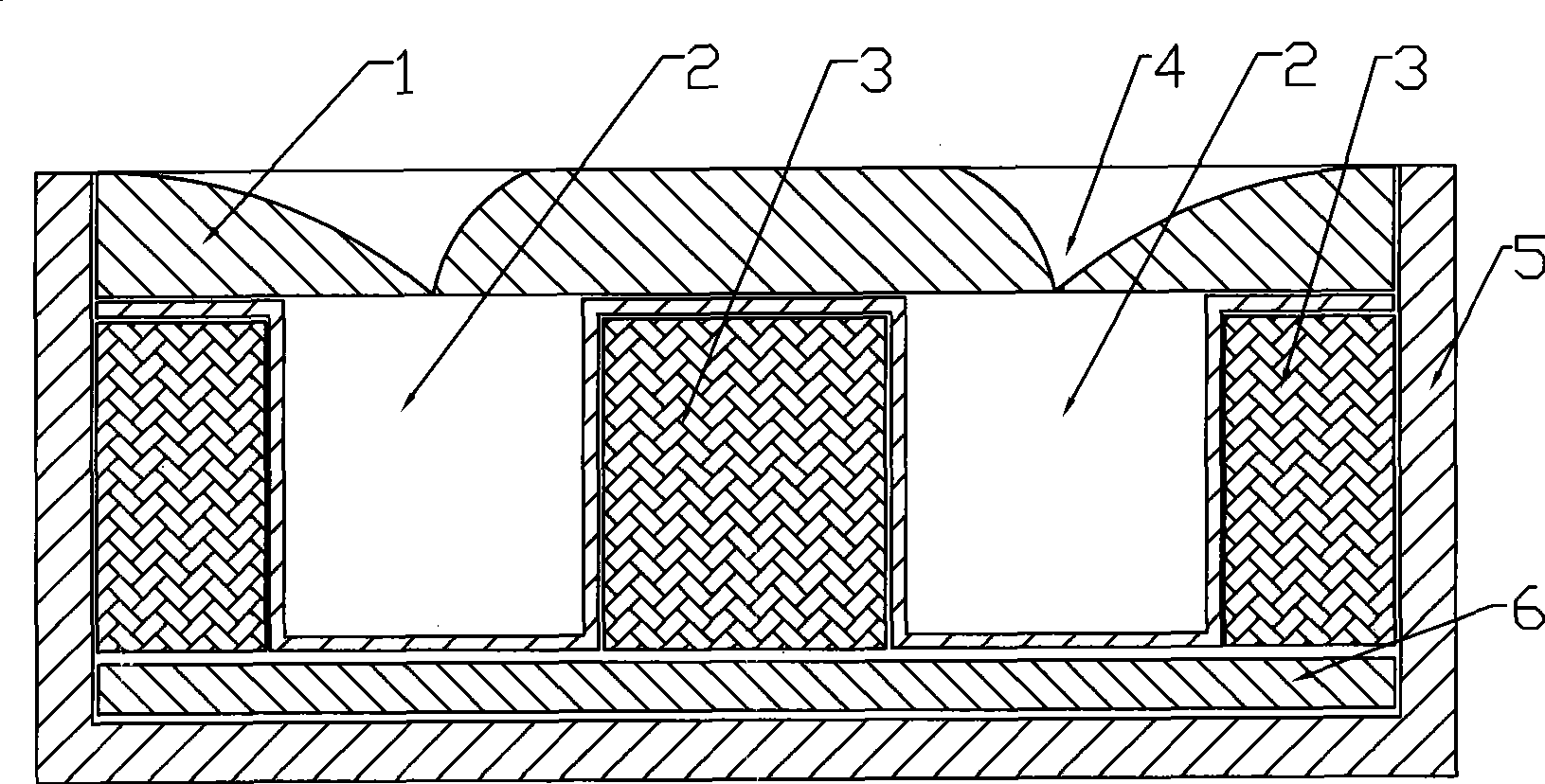

Embodiment 1

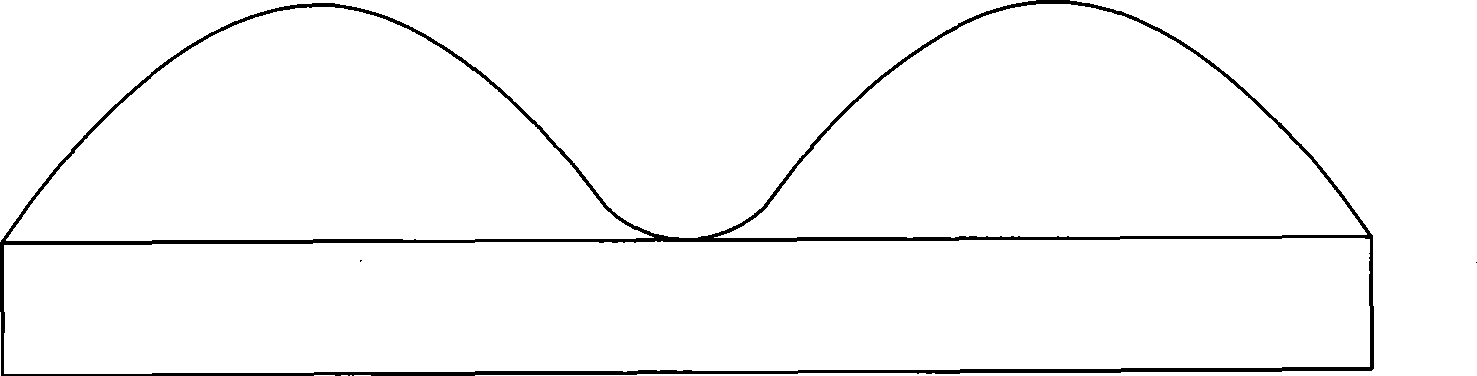

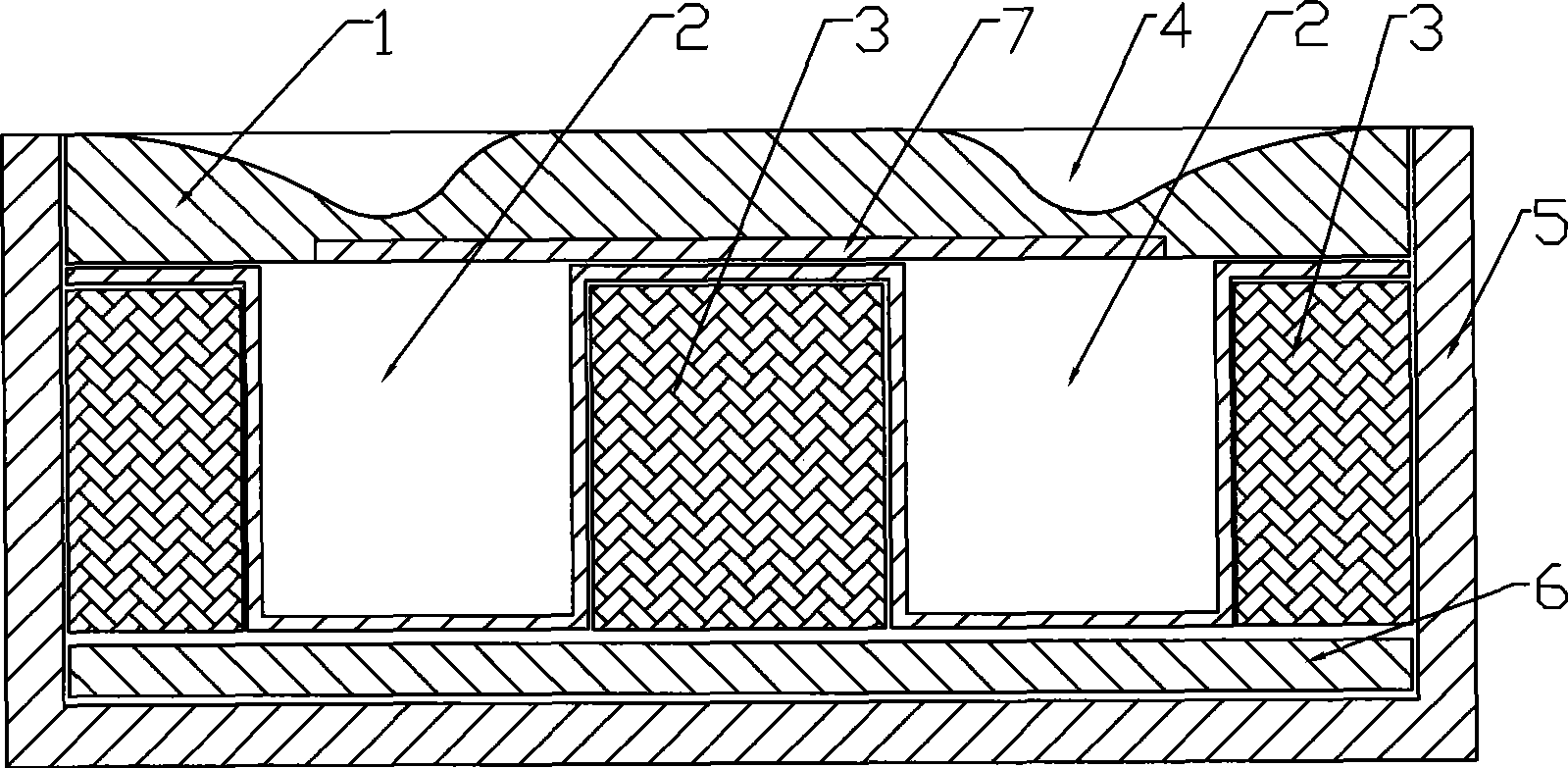

[0015] Embodiment 1, the present invention is composed of a cathode casing 5, a magnetic shoe 6, a magnet 3, a cooling channel 2 and a target 1, etc., and a thin metal sheet 7 for adjusting the magnetic field is arranged between the target 1 and the cooling channel 2 , the metal sheet 7 is made of magnetically conductive metal. The metal sheet 7 can be fixedly connected to the bottom of the target 1 . And a groove can be set at the bottom of the target material 1 , and the metal sheet 7 is embedded in the groove set at the bottom of the target material 1 .

[0016] In the present invention, on the basis of the existing cathode, in order to improve the utilization rate of the target, a metal sheet 7 for adjusting the magnetic field is inserted at the interface between the target material and the cooling channel. And the high-temperature-resistant metal material makes the horizontal magnetic field on the surface of the target uniform in a wider range, and the magnetic field int...

Embodiment 2

[0018] Embodiment 2, the thin metal sheet 7 of the present invention can also be arranged on the bottom of the target 1 in a movable fit, so as to facilitate the adjustment of the magnetic field intensity distribution curve. refer to Figure 1 to Figure 4 , all the other are with embodiment 1.

Embodiment 3

[0019] Embodiment 3, in order to improve the cooling effect, in the present invention, a transition layer with good thermal conductivity can also be provided between the metal foil 7 and the target material 1 . refer to Figure 1 to Figure 4 , and the rest are the same as the above-mentioned embodiment.

[0020] Obviously, the metal flake 7 in the present invention can be a whole piece of metal, or two or more than two pieces of metal flakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com