High-capacity planar magnetron sputtering cathode

A magnetron sputtering, high-power technology, applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., to achieve high power and avoid the effect of cooling medium corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

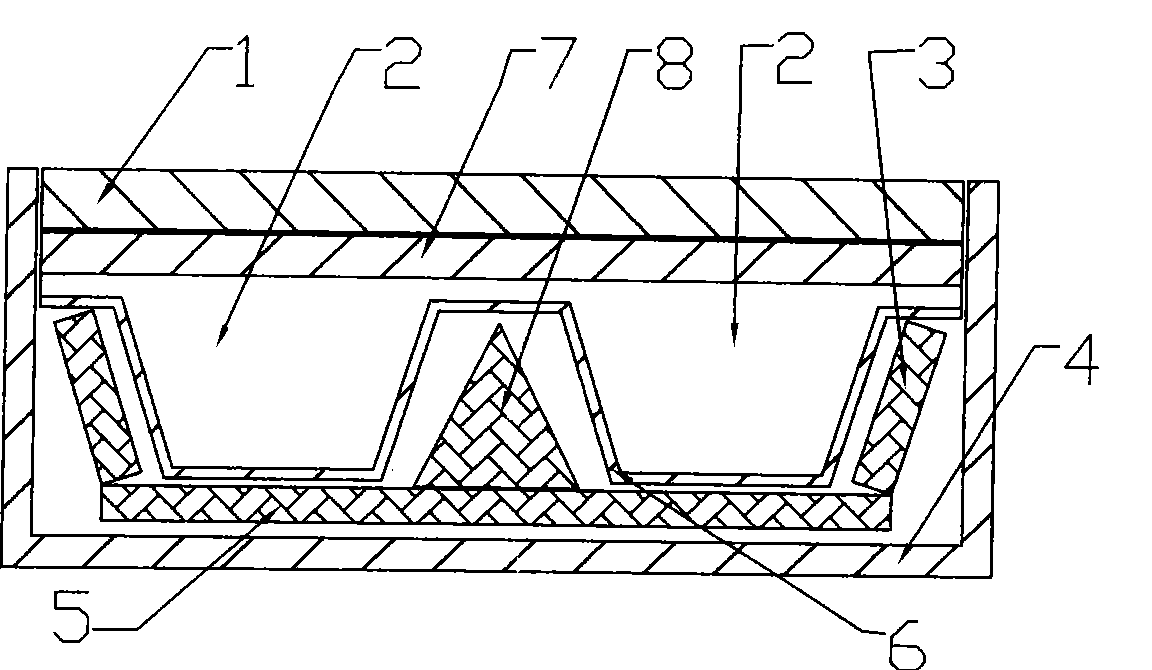

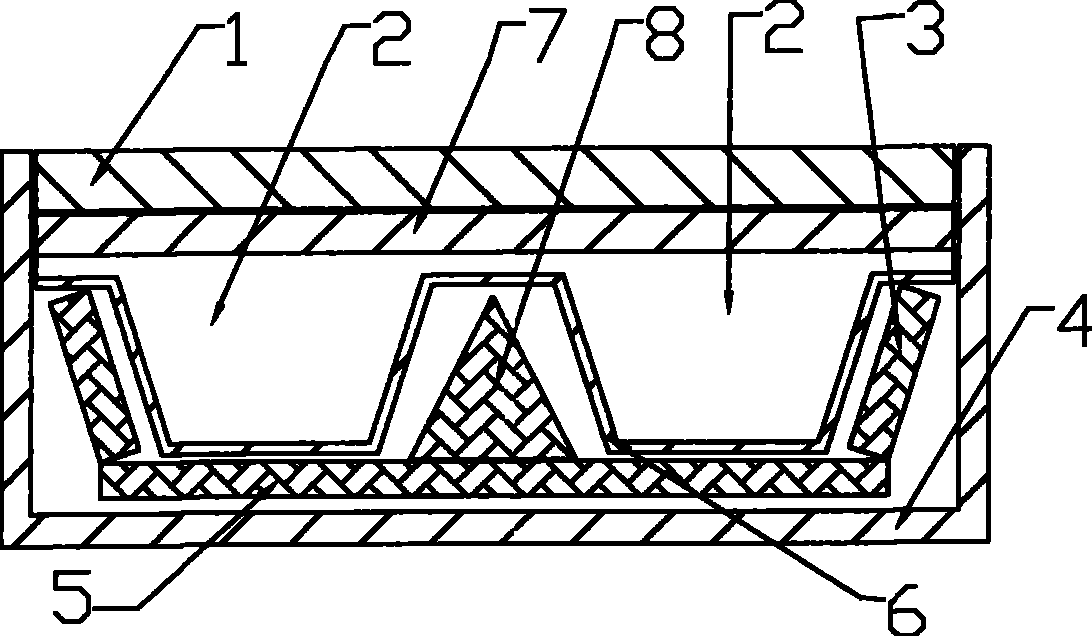

[0012] Embodiment 1, the main part of the present invention is divided into a cathode main part and a target part. It is composed of cathode body 4, magnetic shoe 5, magnet 3, cooling channel 2, etc. The cooling channel shell 6 can be made of metal material, and the target 1 is installed on the upper part of the cathode body 4, in the inner cavity of the cathode body A closed cooling passage 2 is provided, and a magnetic shoe 5 is provided between the bottom of the inner cavity of the cathode body 4 and the cooling passage 2, and a magnet 3 is provided between the cooling passage 2 and the magnetic shoe 5, so that inside the cathode body 4 An independent cooling channel is formed, and the magnet 3 can be a permanent magnet. This structure enables the present invention to provide a large flow of cooling water, or other cooling liquids or gases during the working process, thereby ensuring that the cathode is cooled. The magnetic shoe 5 and the magnet 3 are installed on the lowe...

Embodiment 2

[0013] Embodiment 2, the cooling channel 2 of the present invention can be composed of the cooling channel housing 6 and the heat conduction plate 7, so that the cathode body part is composed of the cathode body 4 and the magnetic shoe 5, the magnet 3, the cooling channel 2, the cooling channel housing 6, the heat conduction The cooling channel shell 6 can be designed as a groove-like structure with an open upper part, and a heat conduction plate 7 is arranged on the upper part of the cooling channel shell 6, and the upper part of the cooling channel shell 6 and the heat conduction plate 7 form a sealed fit, so that The cooling channel shell 6 and the heat conduction plate 7 form the cooling channel 2 together. The heat conduction plate 7 is made of a material with better thermal conductivity, and its thickness is made as small as possible, thereby improving heat conduction, heat dissipation and cooling efficiency. It is the thinner heat conduction plate 7 that is in contact wi...

Embodiment 3

[0014] Embodiment 3, the cross-section of the cooling channel housing 6 of the present invention can be a trapezoidal cooling groove with a wide top and a narrow bottom, and a strip magnet 3 that is matched with the cooling channel housing 6 is provided on the outside of the cooling channel 2 . By designing the cooling channel 2, the shape and installation position of the magnet can be changed; the magnet 3 at different positions can be designed into different shapes and installed according to different angles or positions according to the requirements of working parameters. refer to figure 1 and figure 2 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com