Method for coating film on solar high-temperature heat collection tube used for power generation and horizontal film coating machine

A technology of heat collecting tubes and solar energy, which is applied in the field of vacuum coating special equipment, can solve the problems of difficult maintenance, high equipment, high workshop, etc., and achieve the effect of compact production cycle, good quality and saving auxiliary working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

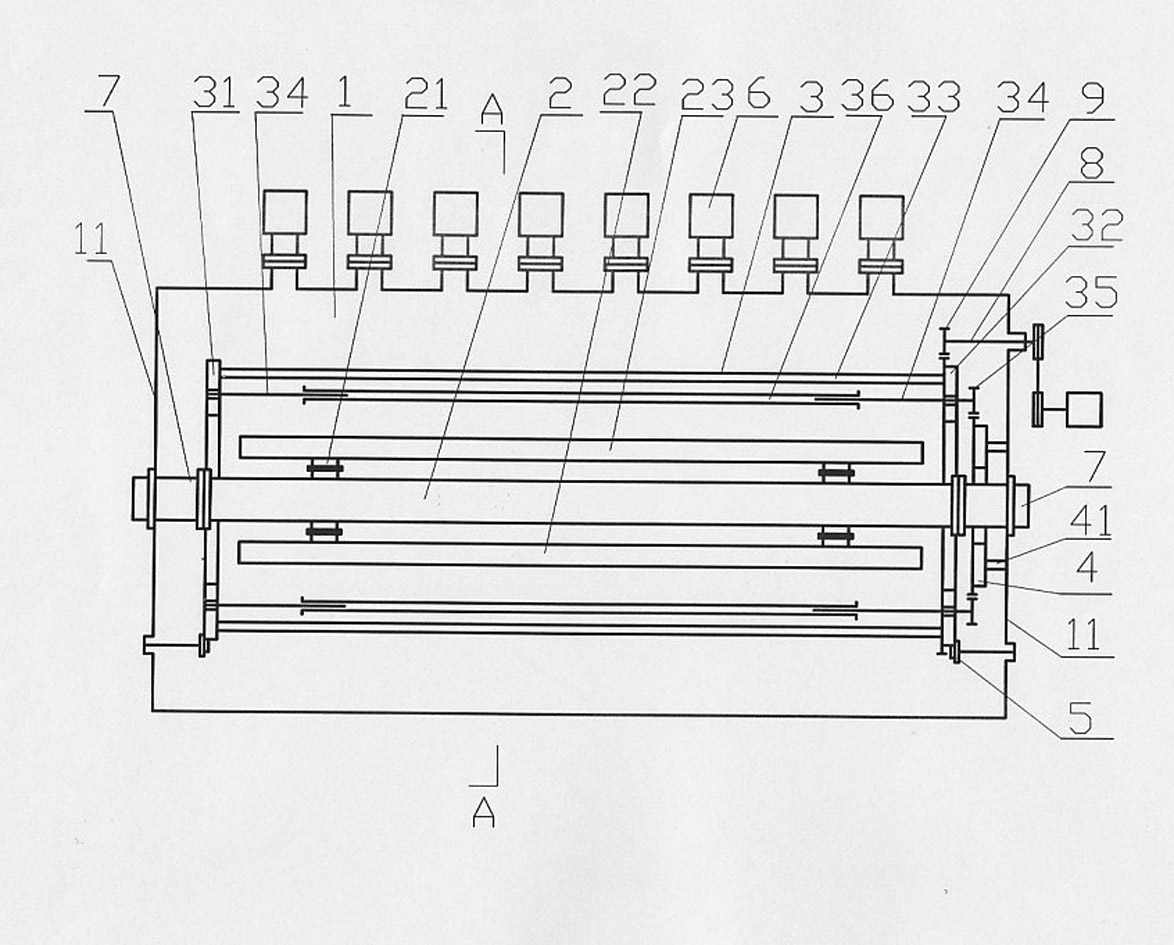

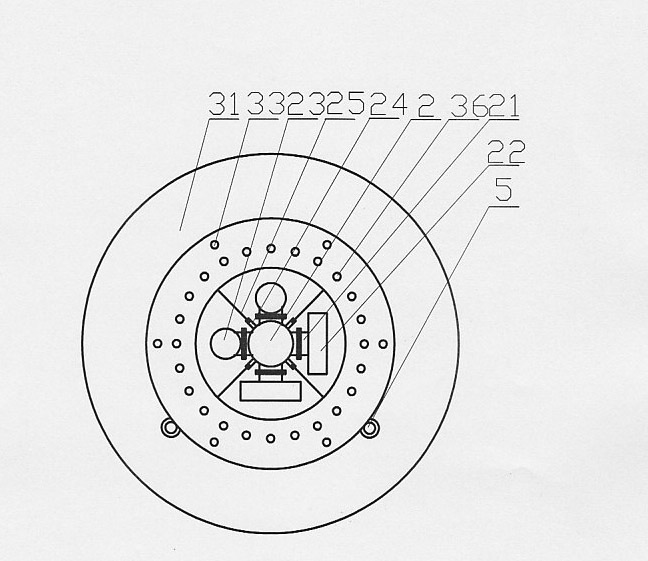

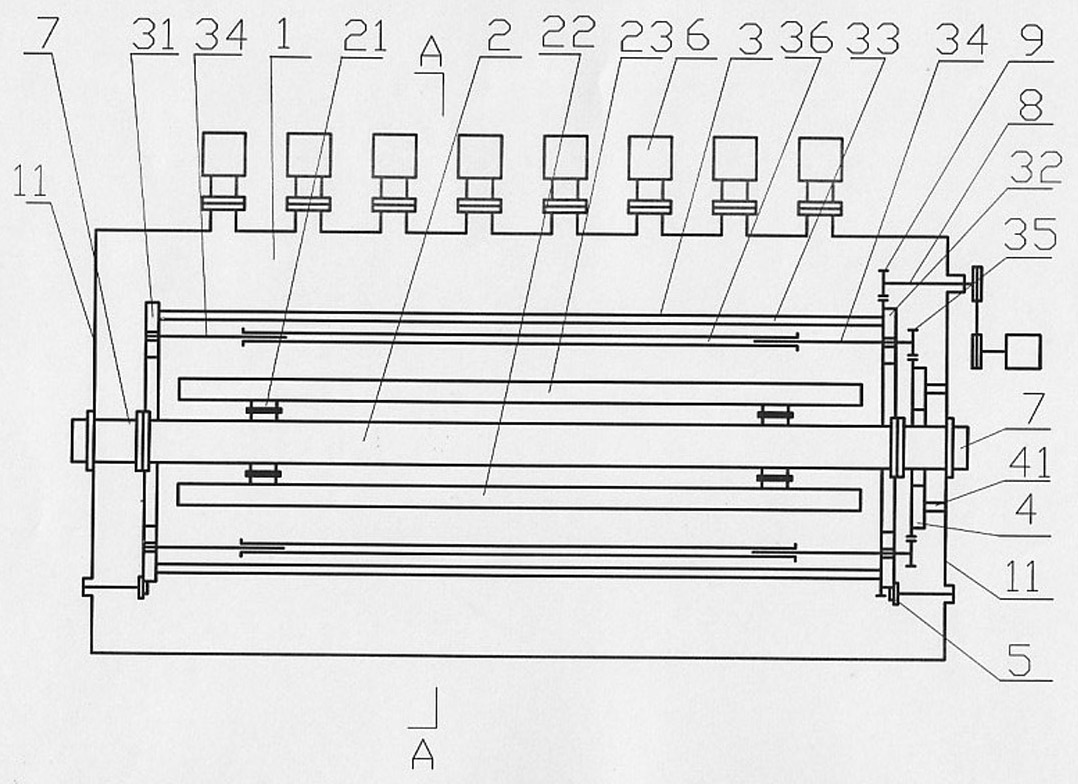

[0022] Such as figure 1 , 2 Shown: a horizontal coating machine for solar high-temperature heat collector tubes for power generation, including a cylindrical vacuum chamber 1 with a horizontal top-opening door structure, a target installation pipe 2, a workpiece rack 3, a fixed toothed plate 4, a support wheel 5 and a rotating drive mechanism , the vacuum chamber 1 is evenly distributed with multiple sets of independent vacuum pumping devices 6 in the length direction. The flange 21 is equipped with a planar magnetron target 22 or / and a rotating cylindrical magnetron target 23, and a partition plate 25 is installed on the target installation pipe fitting 2 through a partition seat 24 to reasonably separate the targets and avoid crossing. pollution, the separator 25 adopts a loose-leaf pluggable structure; the workpiece rack 3 is a rotatable workpiece rack that can be hoisted as a whole, and is placed on four support wheels 5. The left and right rotation shafts 34 are compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com