A circular planar magnetron sputtering target with rotating magnetic poles

A magnetron sputtering and magnetic pole technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problem of low utilization rate of target materials, and achieve the goal of improving utilization rate and sputtering rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

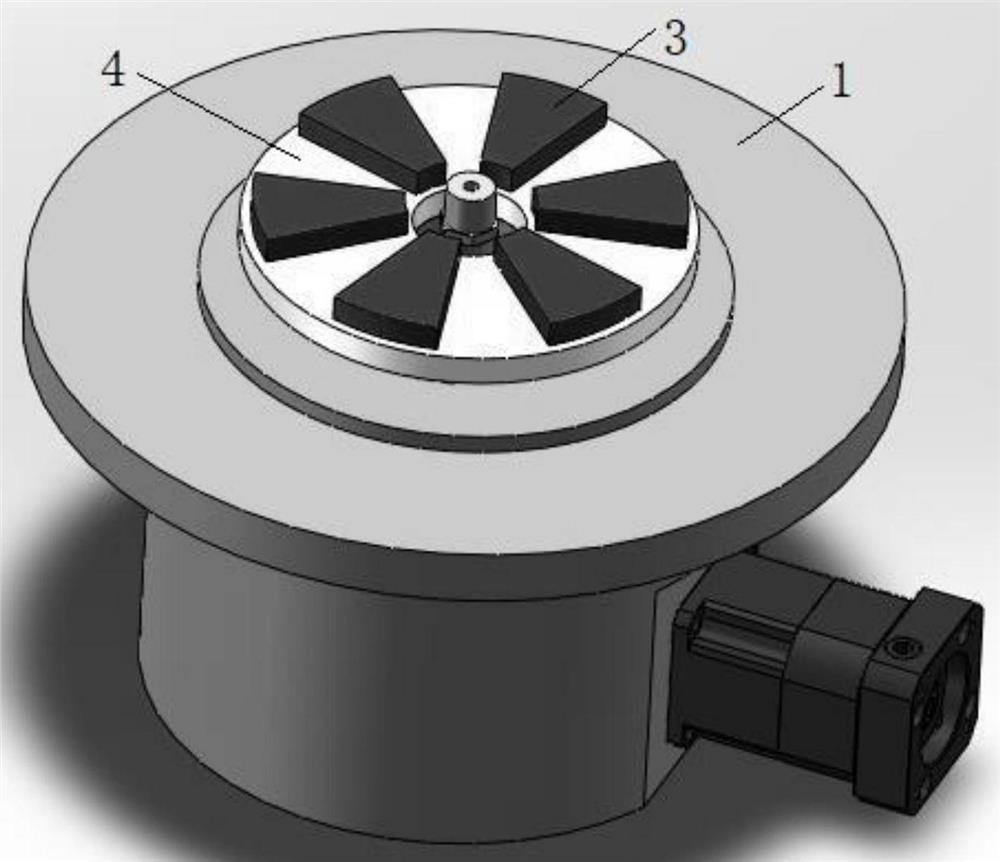

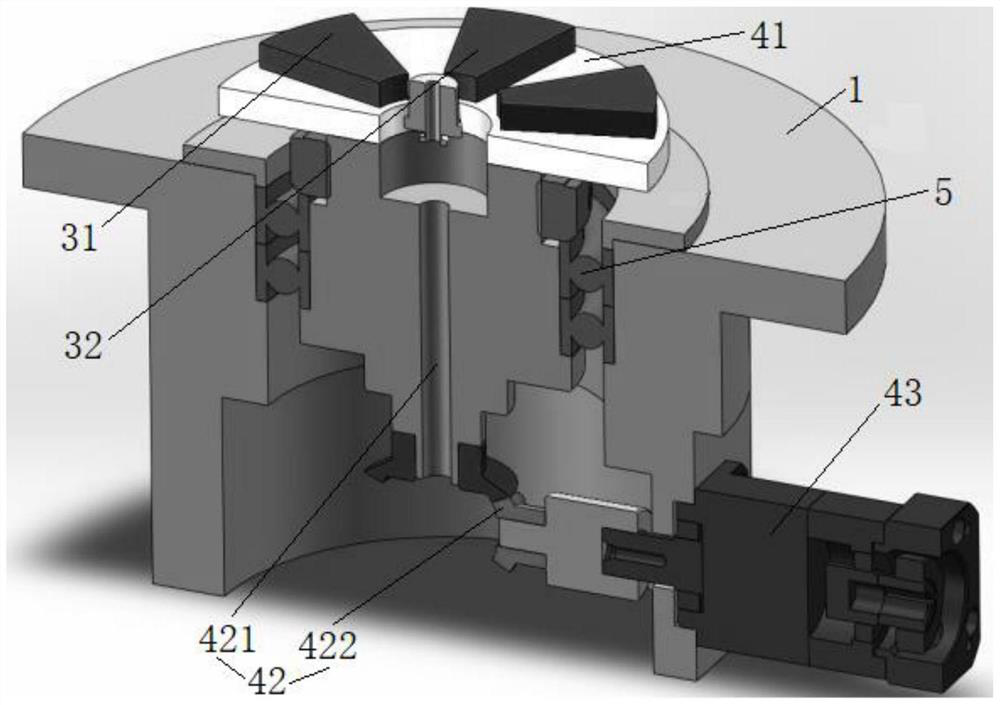

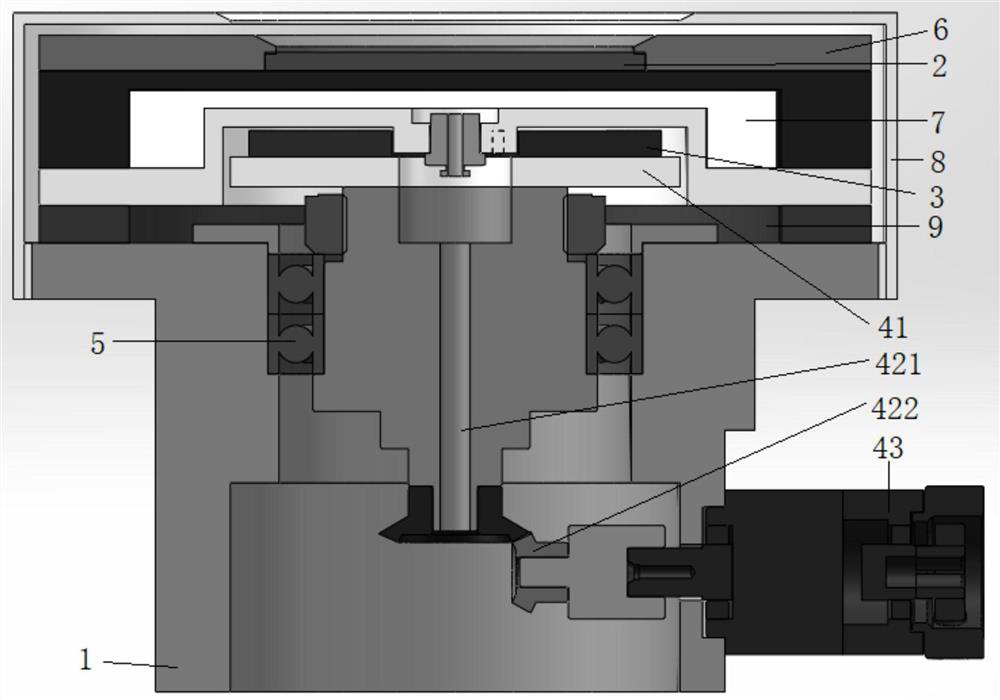

[0044] like figure 1 , figure 2 and image 3 shown.

[0045] This embodiment is a circular planar magnetron sputtering target with rotating magnetic poles, including:

[0046] Target base 1, which is a hollow cylindrical structure;

[0047] The magnetic pole rotation system 4 is arranged on the target base 1 and is movably connected with the target base 1; the magnetic pole rotation system 4 is a rotatable cylindrical structure, and the magnetic pole rotation system 4 is coaxial with the target material 2;

[0048] The magnetic pole 3 is arranged on the magnetic pole rotation system 4 and driven to rotate by the magnetic pole rotation system 4 .

[0049] With such a structure, the present invention places a plurality of magnetic poles 3 evenly distributed along the radial direction of the magnetic pole rotation system 4, so that the magnetic induction lines are arranged along the circumferential direction of the target material 2, and the magnetic poles 3 can be rotated; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com