High-capacity planar magnetron sputtering cathode

A magnetron sputtering, high-power technology, applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve problems such as degaussing, achieve high power, and avoid the effect of cooling medium corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

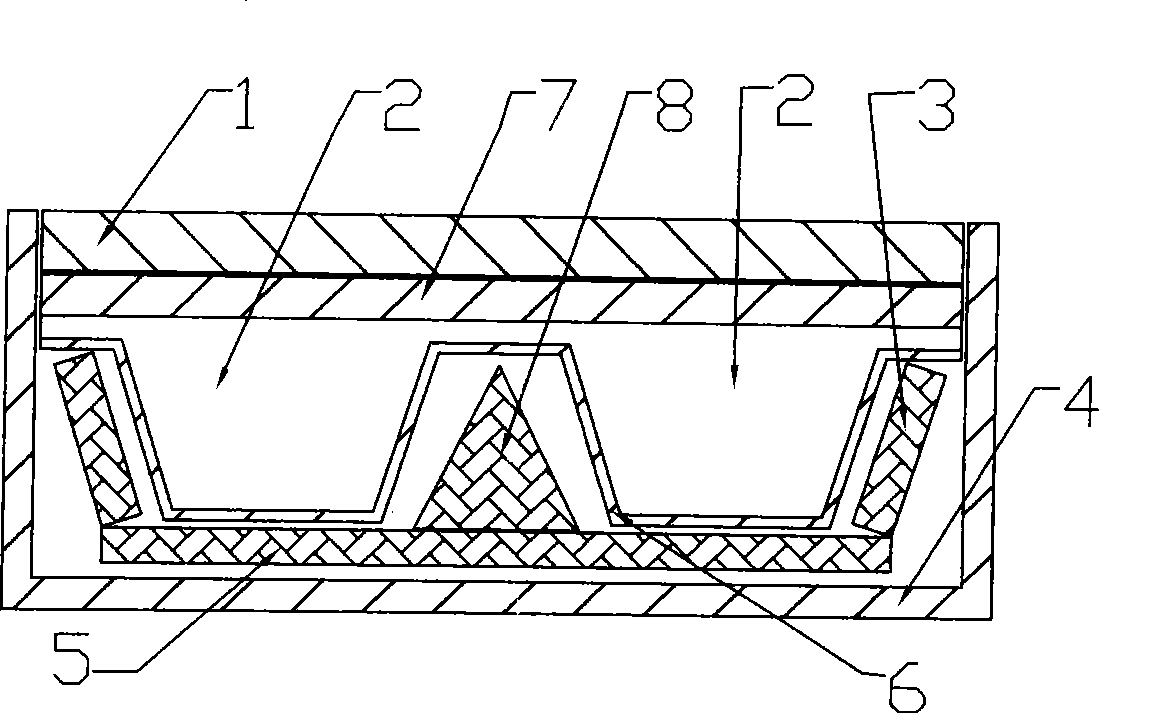

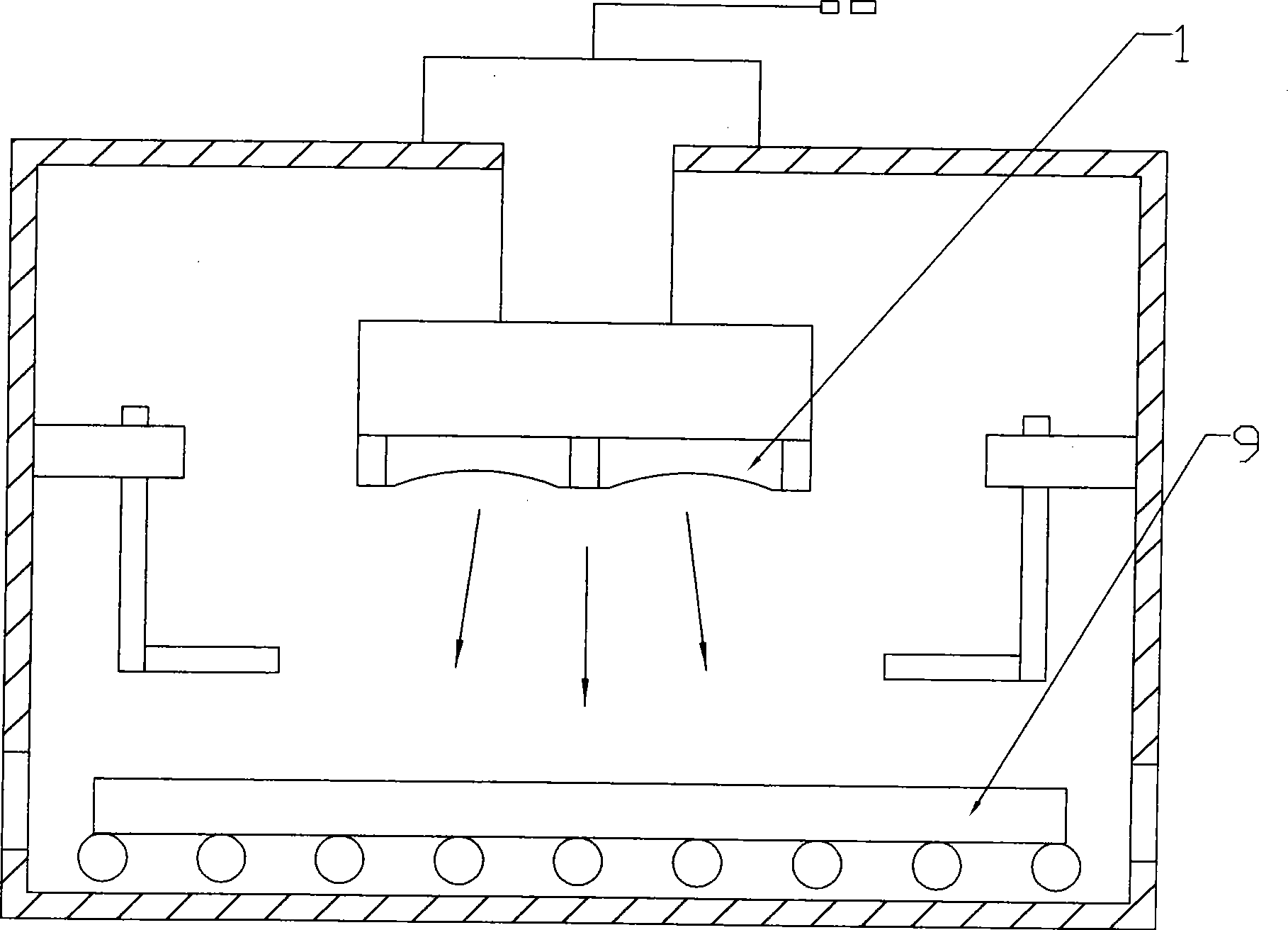

[0010] Embodiment 1, the main part of the present invention is divided into a cathode main part and a target part. It is composed of cathode body 4, magnetic shoe 5, magnet 3, cooling channel 2, etc. The cooling channel shell 6 can be made of metal material, and the target 1 is installed on the upper part of the cathode body 4, in the inner cavity of the cathode body A closed cooling passage 2 is provided, and a magnetic shoe 5 is provided between the bottom of the inner cavity of the cathode body 4 and the cooling passage 2, and a magnet 3 is provided between the cooling passage 2 and the magnetic shoe 5, so that inside the cathode body 4 An independent cooling channel is formed, and the magnet 3 can be a permanent magnet. This structure enables the present invention to provide a large flow of cooling water, or other cooling liquids or gases during the working process, thereby ensuring that the cathode is cooled. The magnetic shoe 5 and the magnet 3 are installed on the lowe...

Embodiment 2

[0011] Embodiment 2, the cooling channel 2 of the present invention can be composed of the cooling channel housing 6 and the heat conduction plate 7, so that the cathode body part is composed of the cathode body 4 and the magnetic shoe 5, the magnet 3, the cooling channel 2, the cooling channel housing 6, the heat conduction The cooling channel shell 6 can be designed as a groove-like structure with an open upper part, and a heat conduction plate 7 is arranged on the upper part of the cooling channel shell 6, and the upper part of the cooling channel shell 6 and the heat conduction plate 7 form a sealed fit, so that The cooling channel shell 6 and the heat conduction plate 7 form the cooling channel 2 together. The heat conduction plate 7 is made of a material with better thermal conductivity, and its thickness is made as small as possible, thereby improving heat conduction, heat dissipation and cooling efficiency. It is the thinner heat conduction plate 7 that is in contact wi...

Embodiment 3

[0012] Embodiment 3, the cross-section of the cooling channel housing 6 of the present invention can be a trapezoidal cooling groove with a wide top and a narrow bottom, and a strip magnet 3 that is matched with the cooling channel housing 6 is provided on the outside of the cooling channel 2 . By designing the cooling channel 2, the shape and installation position of the magnet can be changed; the magnet 3 at different positions can be designed into different shapes and installed according to different angles or positions according to the requirements of working parameters. refer to figure 1 and figure 2 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com