Method for improving utilization rate of rectangular planar magnetron sputtering cathode target material

A magnetron sputtering and cathode target technology, which is applied in sputtering coating, metal material coating process, ion implantation plating, etc., can solve the problem of low utilization rate of target materials, and achieve the goal of improving utilization rate and reducing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

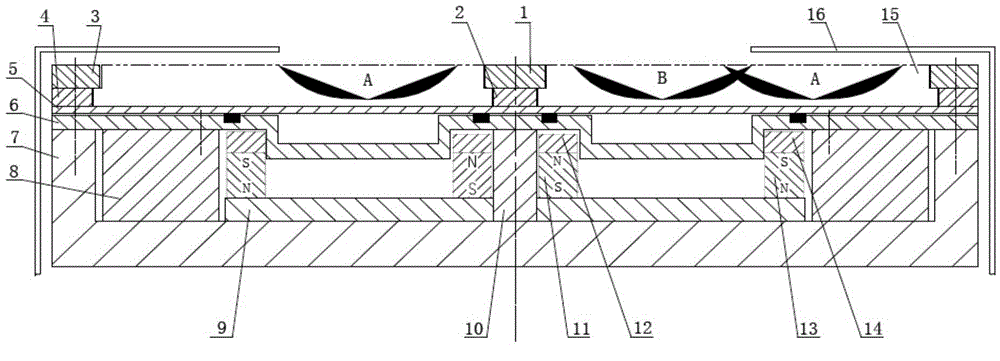

[0019] Such as figure 1 As shown, the rectangular planar magnetron sputtering cathode of a method for improving the utilization rate of the rectangular planar magnetron sputtering cathode includes a middle target bead 1, a middle bead 2, a side target bead 3, an edge bead 4, and a back plate 5. Cooling plate 6, cathode seat 7, support block 8, magnetic yoke 9, center column 10, middle magnet 11, middle magnetic shoe 12, side magnet 13, side magnetic shoe 14 and target 15, characterized in that the target passes through Two installations, two sputtering, the specific method is: when the target is installed for the first time, after sputtering, the etching area is located on one side of the target; then the target is rotated 180° horizontally and then reinstalled on the cathode , the second sputtering is performed, and the two etching areas are just connected to form a larger etching area, which improves the utilization rate of the target.

[0020] The cathode seat of the recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com