All-vanadium redox flow battery cathode electrolyte containing additive

A technology of all-vanadium redox flow battery and positive electrolyte, which is applied in the direction of battery electrodes, electrolytes, regenerative fuel cells, etc., can solve the problems of increasing the cost of VFB system, low system energy density, etc., achieve stable operation and improve high temperature thermal stability properties, and the effect of improving the coordination environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Prepare 1.8M pentavalent vanadium solution by electrolysis, add 1mM, 2mM and 5mM ammonium paratungstate to 10mL pentavalent vanadium solution respectively, mix thoroughly and stir evenly, and place together with the blank 1.8M pentavalent vanadium solution sample in a water bath at 50°C Heated in medium temperature, observed the state of the solution, and investigated the effect of different additions of ammonium paratungstate on the thermal stability of pentavalent vanadium.

[0015] Table 1 The effect of different contents of ammonium paratungstate on the stability of the electrolyte

[0016]

[0017]

[0018] The mechanism of action of additives is the focus of many research works. When pentavalent vanadium is placed in a high-temperature water bath environment, the blank pentavalent vanadium solution quickly produces red V 2 o 5 precipitation. However, the stability time of pentavalent vanadium added with ammonium paratungstate is extended with the increase ...

Embodiment 2

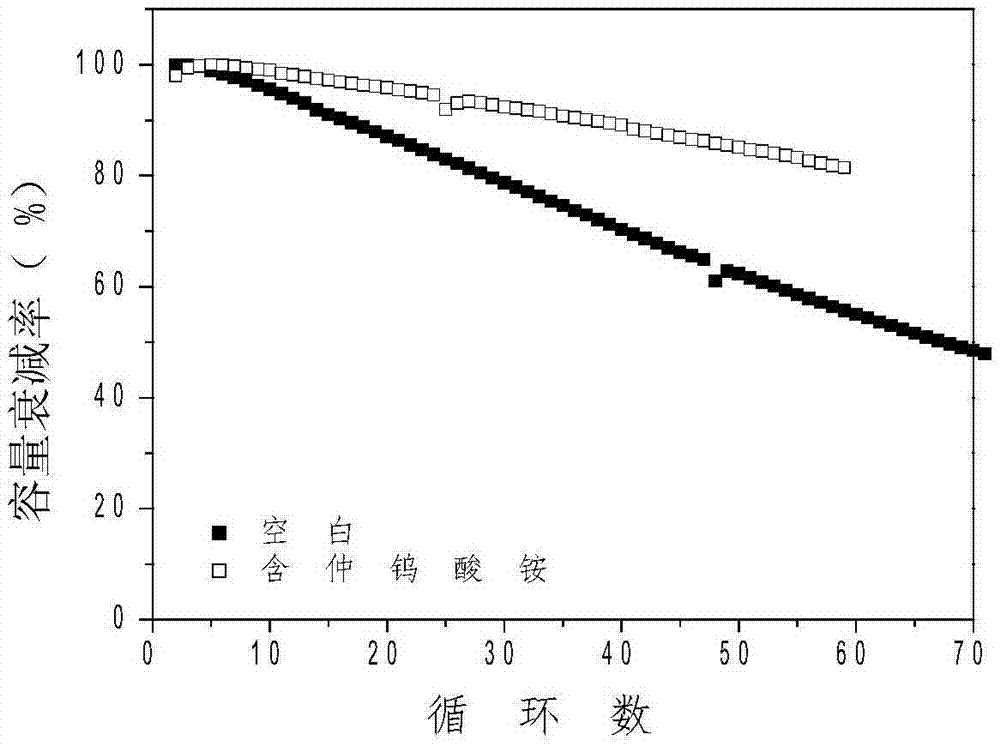

[0020] To 60mL catholyte (1.6M VOSO 4 +3M H 2 SO 4 ) was added into 5mM ammonium paratungstate, stirred evenly and completely dissolved to prepare the electrolyte solution to be tested. Electrolyte containing ammonium paratungstate and blank electrolyte (1.6M VOSO 4 +3M H 2 SO 4 ) as the positive electrode electrolyte, 60mL of 1.6M V 3+ +3M H 2 SO 4 It is used as the negative electrode electrolyte to assemble two all-vanadium redox flow cells. Among them, the battery separator is Nafion115 (Dupont), and the effective area of the membrane is 48cm 2 , the electrode is activated carbon felt, the bipolar plate is graphite plate, and the current density is 80mA cm -2 . The single cell is charged and discharged at a constant current at 50°C, and the cut-off voltage is 1.0-1.55V, thus obtaining the following figure 1 The battery capacity decay curve shown. When the battery reaches the end of charging, due to the instability of pentavalent vanadium ions in the electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com