Method for preparing high-purity molybdenum trioxide

A molybdenum trioxide and high-purity technology, applied in the field of preparation of high-purity molybdenum trioxide, can solve the problems of large differences in the control of baking process parameters, large fluctuations in product quality, low process repeatability, etc., and can overcome many problems. Temperature zone baking, good particle size consistency, and the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of the present embodiment high-purity molybdenum trioxide comprises the following steps:

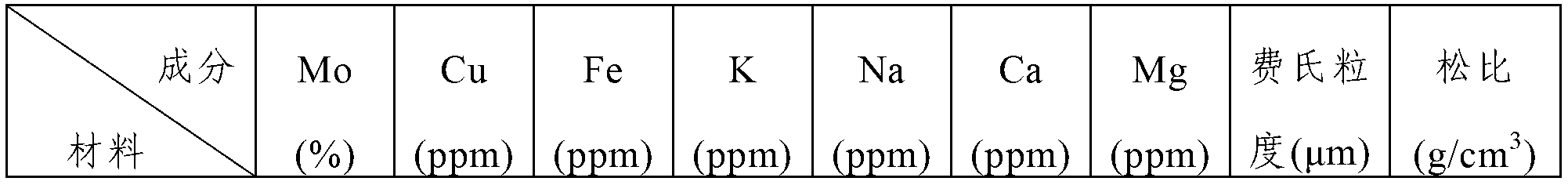

[0021] Step 1. Sieve the ammonium dimolybdate; the specific system of the sieving process is: first pass the ammonium dimolybdate through a 20-mesh sieve to get the sieve, and then pass the 120-mesh sieve to get the sieve. Oversieve; The typical component analysis data of described ammonium dimolybdate is shown in Table 1;

[0022] Step 2, place the ammonium dimolybdate after sieving in step 1 in a muffle furnace, and keep it warm for 1 hour at a temperature of 250°C for pre-baking treatment; the dimolybdate after pre-baking treatment The mass percent composition of molybdenum in ammonium is 61.12%;

[0023] Step 3, pass the ammonium dimolybdate after the prebaking process in step 2 through a 20-mesh sieve to obtain a sieved powder;

[0024] Step 4, place the sieved powder described in step 3 in a muffle furnace, heat it for 2 hours at a temperature of 440...

Embodiment 2

[0030] The preparation method of the present embodiment high-purity molybdenum trioxide comprises the following steps:

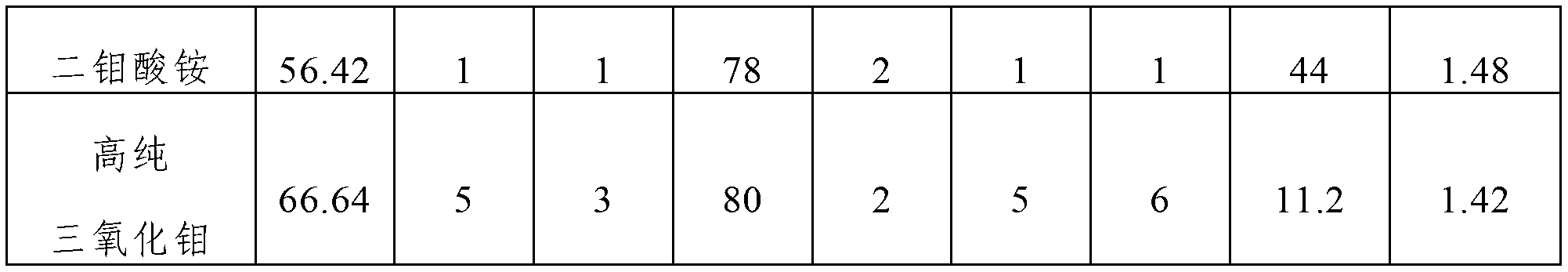

[0031] Step 1. Sieve the ammonium dimolybdate; the specific system of the sieving process is: first pass the ammonium dimolybdate through a 20-mesh sieve to get the sieve, and then pass the 120-mesh sieve to get the sieve. Oversieve; The typical component analysis data of described ammonium dimolybdate is shown in Table 2;

[0032] Step 2, place the ammonium dimolybdate after sieving in step 1 in a muffle furnace, and keep it warm for 1.5h at a temperature of 245°C for pre-roasting; the pre-baked dimolybdenum The mass percentage composition of molybdenum in ammonium acid is 61.22%;

[0033] Step 3, pass the ammonium dimolybdate after the prebaking process in step 2 through a 20-mesh sieve to obtain a sieved powder;

[0034] Step 4, place the sieved powder described in step 3 in a muffle furnace, heat it for 1.5 hours at a temperature of 440°C for roasting ...

Embodiment 3

[0039] The preparation method of the present embodiment high-purity molybdenum trioxide comprises the following steps:

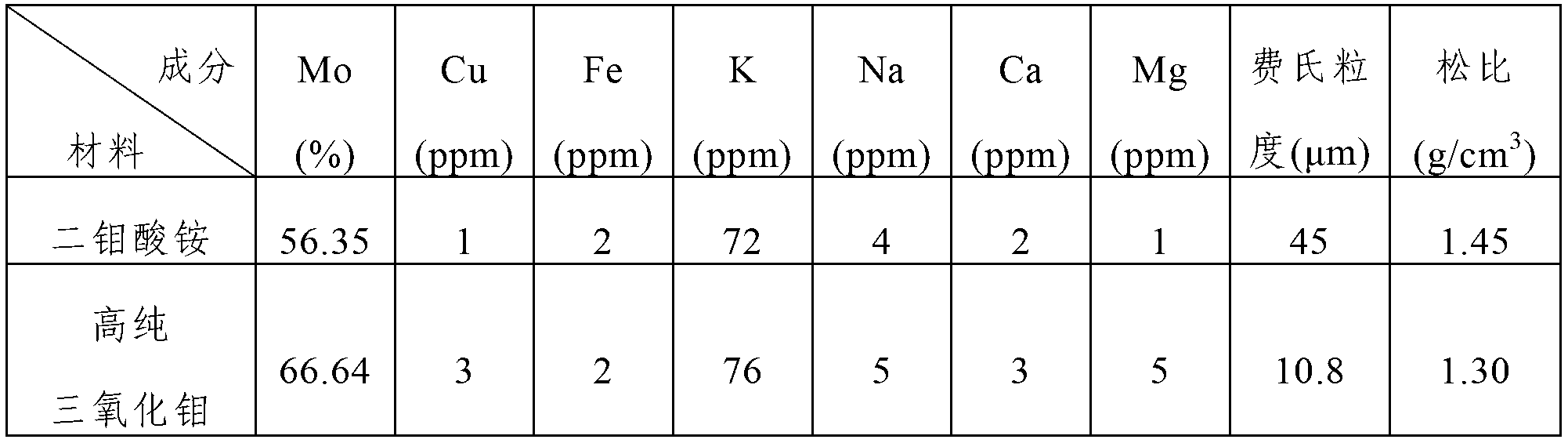

[0040] Step 1. Sieve the ammonium dimolybdate; the specific system of the sieving process is: first pass the ammonium dimolybdate through a 20-mesh sieve to get the sieve, and then pass the 120-mesh sieve to get the sieve. Oversieve; The typical component analysis data of described ammonium dimolybdate is shown in Table 3;

[0041] Step 2, place the ammonium dimolybdate after sieving in step 1 in a muffle furnace, and keep it warm for 1h at a temperature of 255°C for pre-roasting; the pre-baked dimolybdate The mass percent composition of molybdenum in ammonium is 61.35%;

[0042] Step 3, pass the ammonium dimolybdate after the prebaking process in step 2 through a 20-mesh sieve to obtain a sieved powder;

[0043] Step 4, place the sieved powder described in step 3 in a muffle furnace, heat it for 1.5 hours at a temperature of 430°C for roasting treatment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com