Inorganic bonding agent and manufacturing method thereof

A technology of inorganic adhesive and manufacturing method, applied in the directions of inorganic adhesive, polymer adhesive additive, non-polymer adhesive additive, etc., can solve the problems of poor water resistance and poor stability, and improve the solid content , The effect of improving permeability and shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

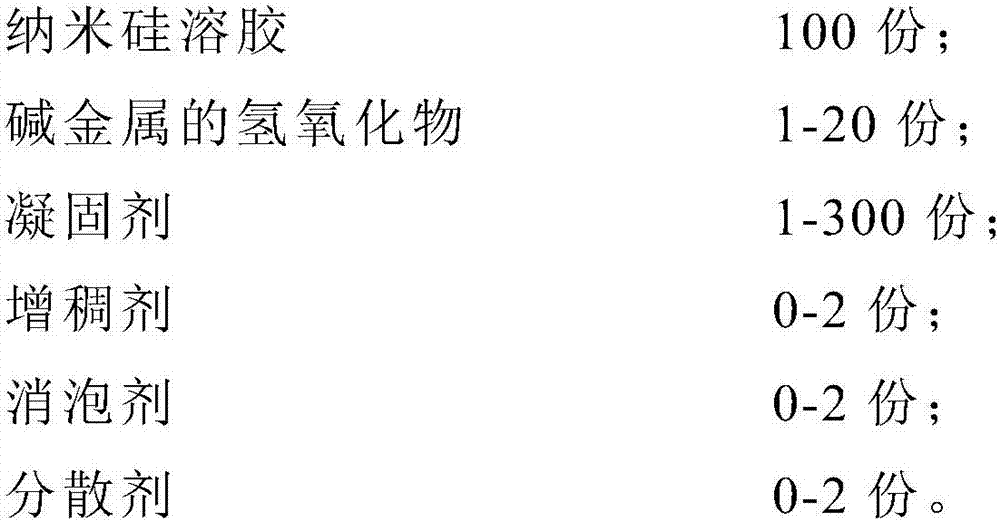

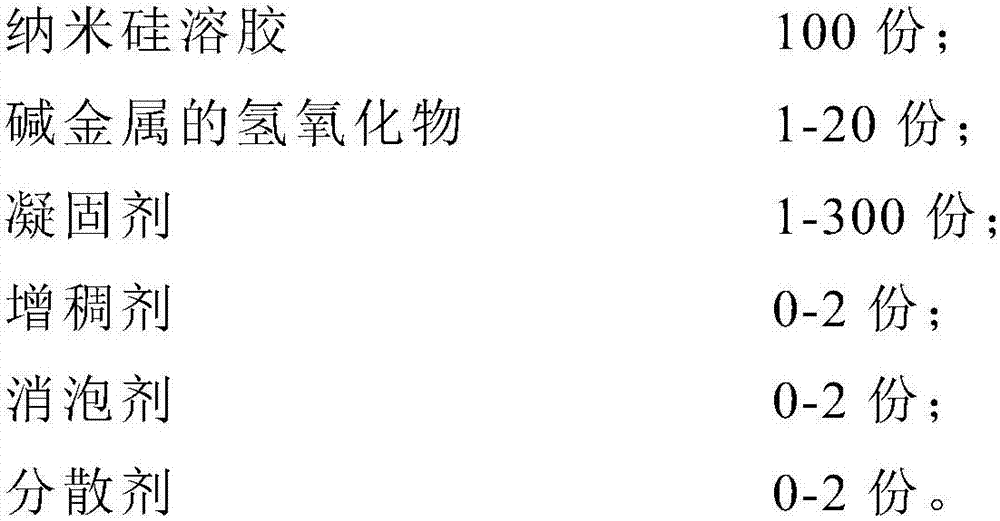

Method used

Image

Examples

Embodiment 1

[0043] A kind of manufacturing method of inorganic binder, 6.0g potassium hydroxide is added to 100g of nano-silica sol of mass concentration 25% at 60 ℃, continue ultrasonic stirring until the difference between pH and stable pH is less than 0.2, the modulus of the obtained silicate solution is 8.0. The difference between the pH and the stable pH in this embodiment is less than 0.2 means that the pH of the aqueous phase increases after potassium hydroxide is added and dissolved, and an equilibrium pH value will be obtained when the hydroxide radical hydrolysis / hydration reaction reaches equilibrium. Under ultrasonic stirring, as the hydrolysis / hydration continues, the pH gradually drops to a stable pH value. When the difference between the equilibrium pH value and the stable pH value is less than 0.2, the pH value is considered to be stable.

[0044] Slowly add 100g of kaolin and 50g of alkali-free glass fiber powder to the silicate solution at a temperature of 40°C. After ul...

Embodiment 2

[0047] A kind of manufacture method of inorganic binder, add 4.4g potassium hydroxide and 1.0g lithium hydroxide to 100g of nano-silica sol of mass concentration 20% at 50 ℃, continue ultrasonic stirring until the difference between pH and stable pH is less than 0.2, the obtained The silicate solution modulus is 5.5.

[0048] Slowly add 2 g of potassium methyl silicate dropwise to the silicate solution at 40° C., add thickener and defoamer, and continue ultrasonic stirring for 30 minutes until the solution is homogeneous and transparent.

[0049] Mix the modified silicate solution with 500-mesh spherical zinc powder at a mass ratio of 1:3, or mix with 300-mesh spherical aluminum powder at a mass ratio of 1:1.5, then spray it on the tinplate plate, and test the adhesion of the coating after curing It is grade 1, and the surface water contact angle is greater than 90°.

[0050] The obtained adhesive layer can be used as a zinc-rich or aluminum-rich anti-corrosion coating, and t...

Embodiment 3

[0052] A kind of manufacture method of inorganic binder, add 11.9g potassium hydroxide to 100g nano-silica sol of mass concentration 25% at 50 ℃, continue ultrasonic stirring until the difference between pH and stable pH is less than 0.2, the modulus of the obtained silicate solution is 4.0.

[0053] Slowly add 20g of activated alumina and 100g of superfine quartz powder to the silicate solution at 40°C, ultrasonically disperse and grind for 30 minutes, then add thickener and defoamer.

[0054] The obtained inorganic binder can be used as a floor coating, and the surface hardness reaches Mohs 7 after being cured by adding iron oxide pigments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com