Semi-solid-state zinc nickel flow cell

A zinc-nickel liquid and flow battery technology, which is applied in fuel cells, indirect fuel cells, fuel cell grouping, etc., can solve the problems that battery power and capacity cannot be independently designed, and the energy storage capacity of zinc-nickel liquid flow batteries is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

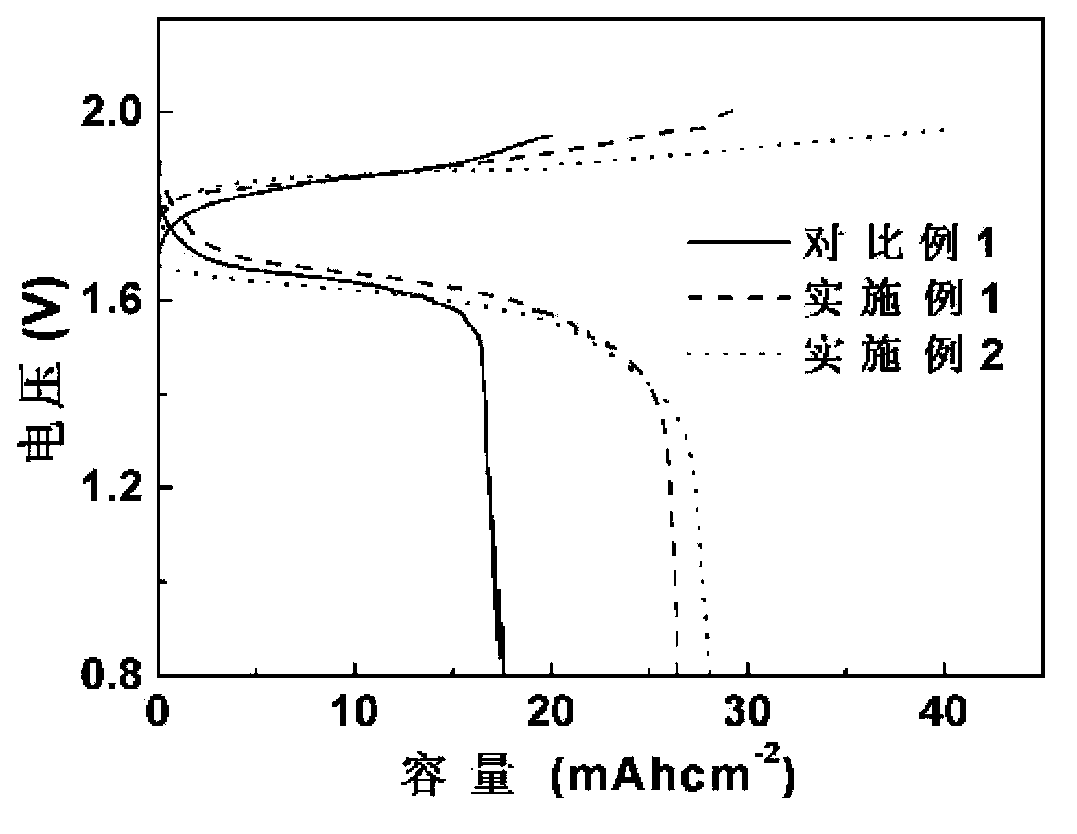

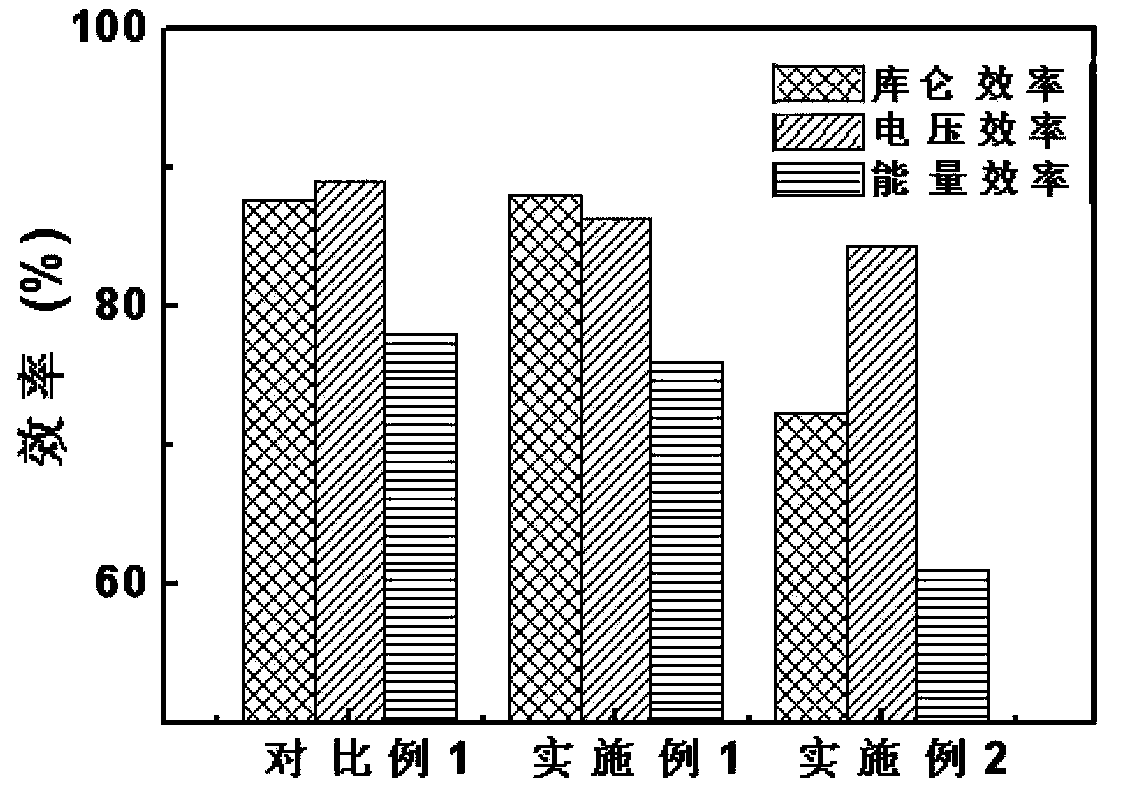

Embodiment 1

[0035] Electrolyte preparation

[0036] Positive electrode electrolyte: Weigh 1.5g of nickel hydroxide powder with a particle size of 50nm and 1.5g of acetylene black, grind them in a mortar for 30 minutes, then transfer the above mixed solids to a beaker, add 1.5g of beta naphthalenesulfonate sodium formaldehyde to condense The solution of compound and 56g potassium hydroxide was settled to 100mL, stirred at room temperature for 4 hours, and ultrasonicated for 2 hours to obtain a suspension containing 15g / L of active material nickel hydroxide.

[0037] Negative electrode electrolyte: Weigh 3.26g of zinc oxide and dissolve it in 100mL of potassium hydroxide solution with a concentration of 10mol / L.

[0038] Battery Assembly:

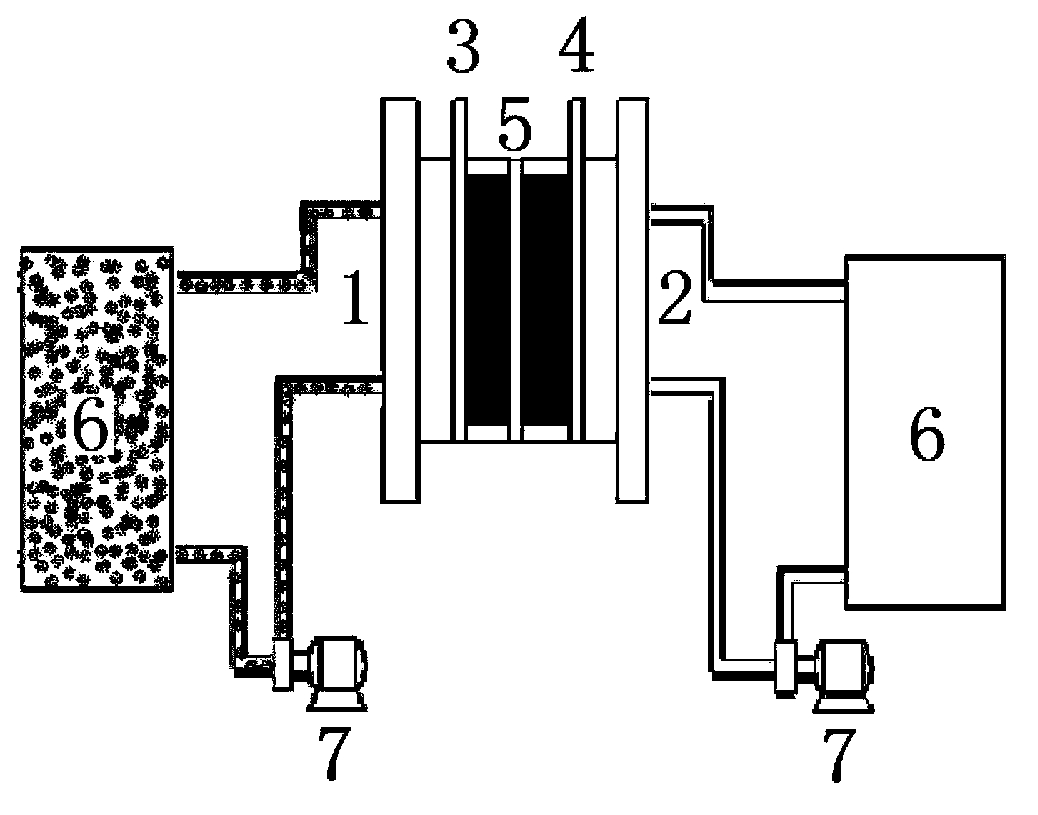

[0039] The single cell adopts 3x3cm positive terminal plate 1 and positive electrode 3 in turn 2 Porous carbon foam, microporous diaphragm 5, negative electrode 4 adopts 3x3cm 2 Pre-galvanized nickel foam, negative and positive terminal plates 2, sing...

Embodiment 2

[0044] Electrolyte preparation

[0045] Positive electrode electrolyte: Weigh 2g of nickel oxide powder with a particle size of 80nm and 1.5g of acetylene black, grind them in a mortar for 30 minutes, then transfer the above mixed solids to a beaker, add 1g of sodium hexametaphosphate, 1g of dodecane Sodium sulfonate and 40 g of sodium hydroxide solution were adjusted to 100 mL, stirred at room temperature for 6 hours, and ultrasonicated for 3 hours to obtain a suspension containing 20 g / L of active material nickel oxide.

[0046] Negative electrode electrolyte: weigh 3.26g of zinc oxide and dissolve it in 100mL of sodium hydroxide solution with a concentration of 10mol / L.

[0047] Battery Assembly:

[0048] The single cell adopts 3x3cm positive terminal plate 1 and positive electrode 3 in turn2 Porous foam nickel ion exchange membrane Nafion117 (5) negative electrode 4 adopts 3x3cm 2 Nickel sheet pre-plated with lead, negative terminal plate 2, single cell structure and sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com