Preparation method of calcium zincate and calcium zincate reclaiming agent at normal temperature

A technology of calcium zincate and desulfurizer, applied in chemical instruments and methods, separation methods, refined hydrocarbon oil, etc., can solve the problems of not providing positive effects, etc., and achieve the effects of improving production safety, reducing costs, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 151.5 grams of Zn (NO 3 ) 2 ·6H 2 O, put in a 1000ml stirred reactor, add 200ml of water, stir at room temperature until the zinc salt is completely dissolved. Then weigh 58.2 grams of Ca(OH) 2 Put the powder in a 400ml beaker, add 200ml water to make Ca(OH) 2 slurry. Ca(OH) 2 The slurry is slowly added to the zinc salt solution until the addition is complete. Stirring was continued for one hour.

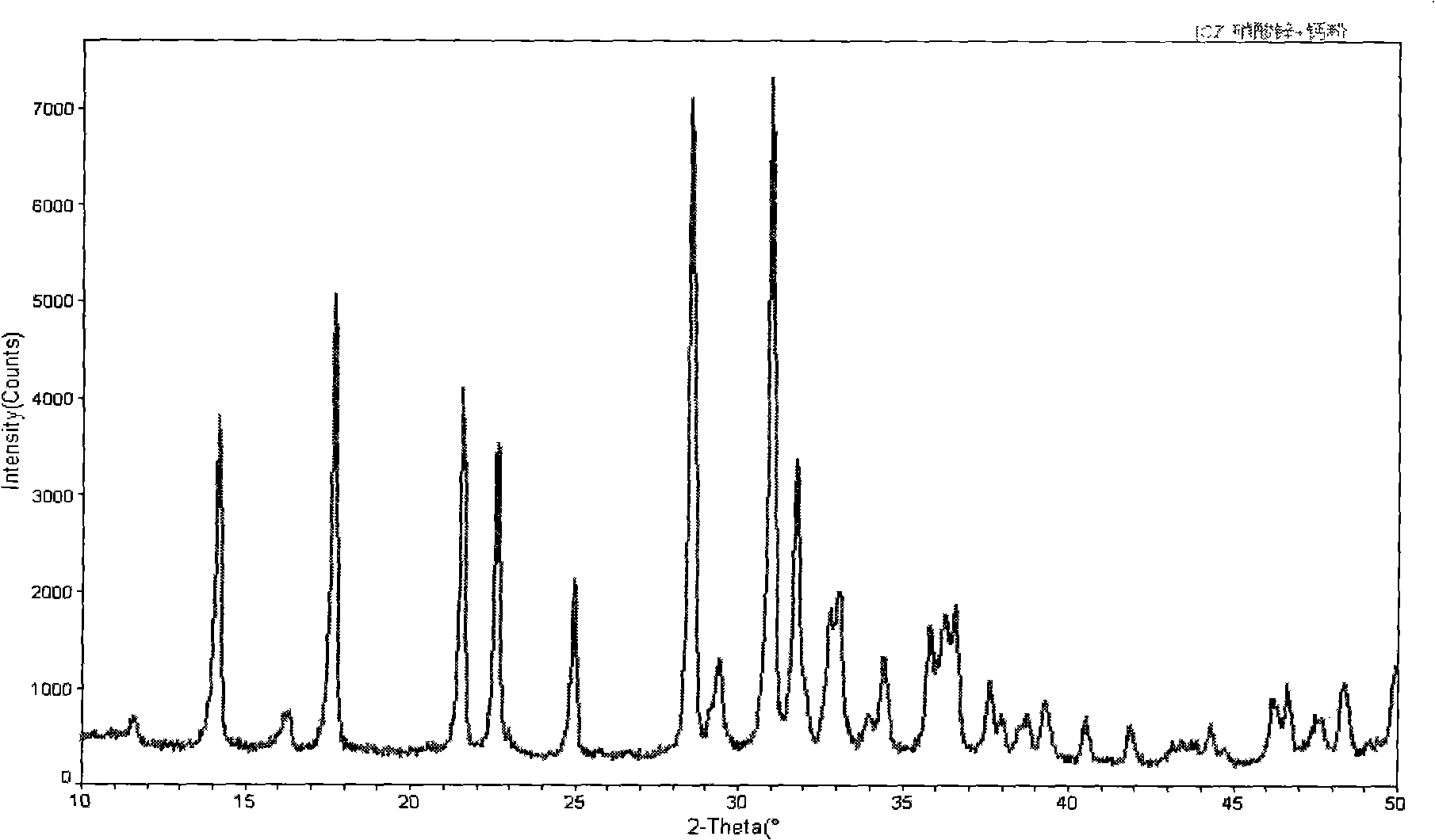

[0041] Filter the precipitate, wash the precipitate three times with 600ml water (each 200ml); the filter cake is dried to obtain the former powder of calcium zincate, which is determined by XRD ( figure 1 ) whose phase is extremely pure CaZn 2 (OH) 6 2H 2 O.

[0042] The calcium zincate raw material was tableted and granulated, and a sample of 40-60 mesh was screened out, and the 4.02% standard H 2 S gas (base gas is high-purity N 2 ), airspeed 3000h -1 1. The one-time breakthrough sulfur capacity is 35.2% at room temperature of 20°C.

Embodiment 2

[0044] Weigh 18.0 grams of calcium zincate in Example 1, 2.0 grams of squash gum, 0.5 grams of kaolin, 0.5 grams of cement, 2.0 grams of barite powder and an appropriate amount of water, and shape it on a small twin-screw extruder to extrude a Ф4 bar-shaped desulfurization agent, and evaluate the sulfur capacity after drying.

[0045] The obtained desulfurizer has a lateral compressive strength of 120N / cm, a bulk specific gravity of 0.90 g / ml, and is powdered to 40-60 meshes, and is prepared with 4.02% standard H 2 S gas (base gas is high-purity N 2 ), airspeed 3000h -1 1. The one-time breakthrough sulfur capacity is 25.1% at room temperature of 20°C.

Embodiment 3

[0047] Weigh 20.0 grams of calcium zincate in Example 1, 3.0 grams of squash gum, 1.0 grams of kaolin and an appropriate amount of water, and shape it on a small twin-screw extruder to extrude a strip-shaped desulfurizer of Ф4, and evaluate the sulfur capacity after drying. The obtained desulfurizer has a lateral compressive strength of 130N / cm, a bulk specific gravity of 0.82 g / ml, is powdered to 40-60 mesh, and is prepared with 4.02% standard H 2 S gas (base gas is high-purity N 2 ), airspeed 3000h -1 1. The one-time breakthrough sulfur capacity is 28.6% at room temperature of 20°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com