Zinc-iron single flow battery

A technology of flow battery and single battery, applied in the field of single liquid flow battery, can solve the problems of low solubility of iron salt and cross-contamination of iron ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

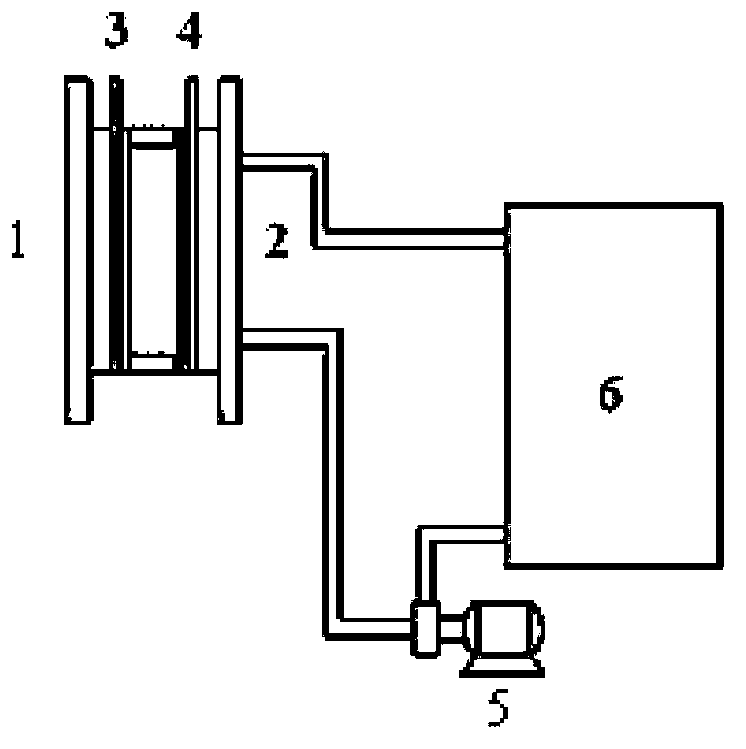

Image

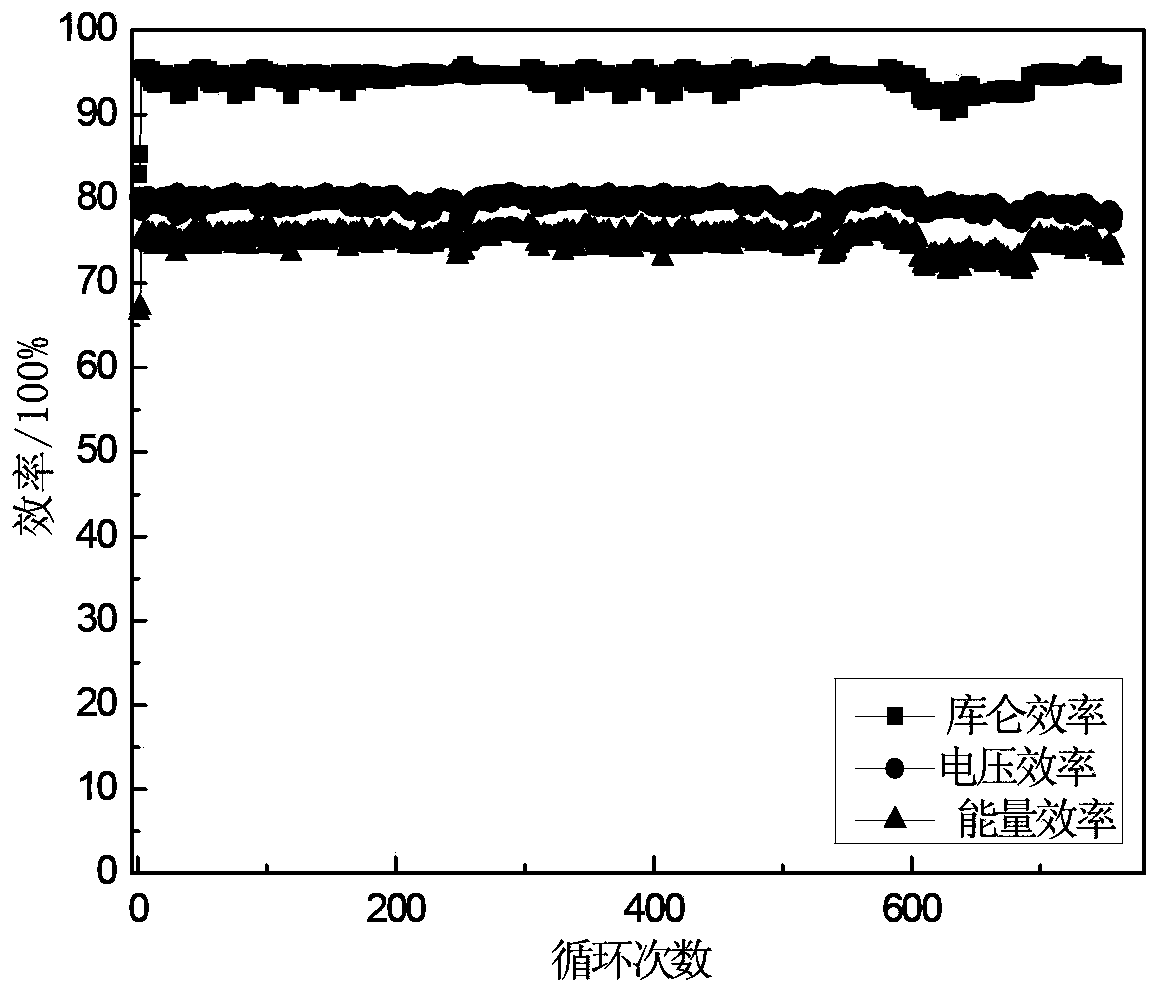

Examples

Embodiment Construction

[0020] Preparation of positive electrode active material:

[0021] Use a reagent bottle to prepare 40mL of 0.05mol / L FeSO 4 Slowly add dropwise to 100mL0.05mol / L KOH solution, stir well with a glass rod to obtain a colorless and clear mixed solution; nitrogen protection; reaction temperature: room temperature; after the reaction is completed, collect the black precipitate by suction filtration and wash repeatedly with deionized water Until the solution was neutral, the well was vacuum-dried in an oven at 100° C. for 12 hours to obtain the positive active material FeO.

[0022] Preparation of positive electrode:

[0023] The prepared positive electrode active material FeO was mixed with acetylene black and PTFE at a mass ratio of 75:15:10, and was thoroughly ground evenly with an agate mortar. Add an appropriate amount of ethanol, scrape evenly on 3x3cm with a blade 2 On the base foam nickel, put it into a vacuum drying oven at 120°C to dry to constant weight, press it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com