Method for the preparation of nanostructures and nanowires

a nanostructure and nanowire technology, applied in the field of nanostructures and nanowires, can solve the problems of not being suitable for nanowire production, not being cost-effective in obtaining nanoscale wires within the aperture, and the process is rather complicated to operate, etc., and is not suitable for using the whole structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

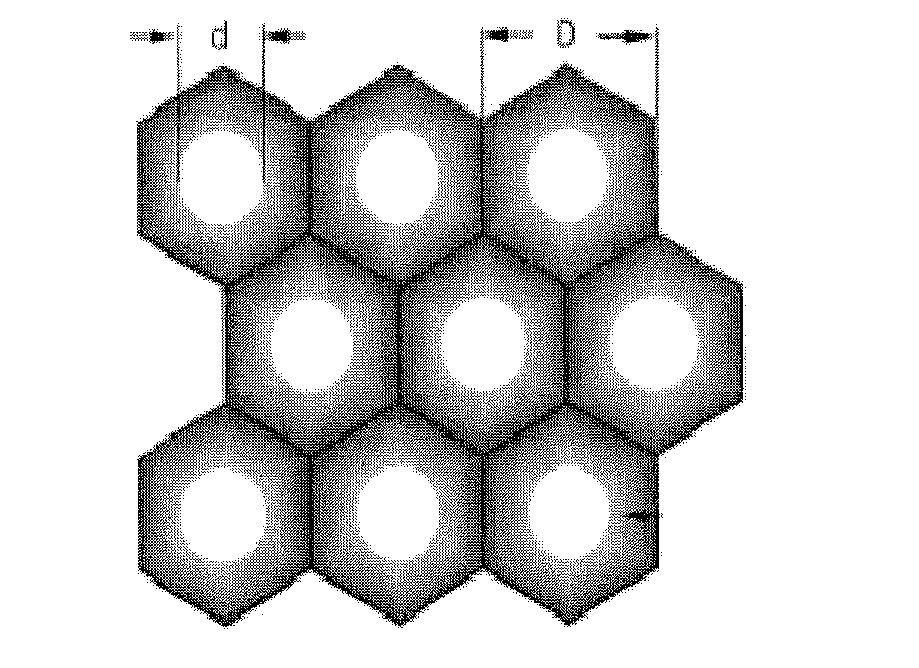

Image

Examples

example 1

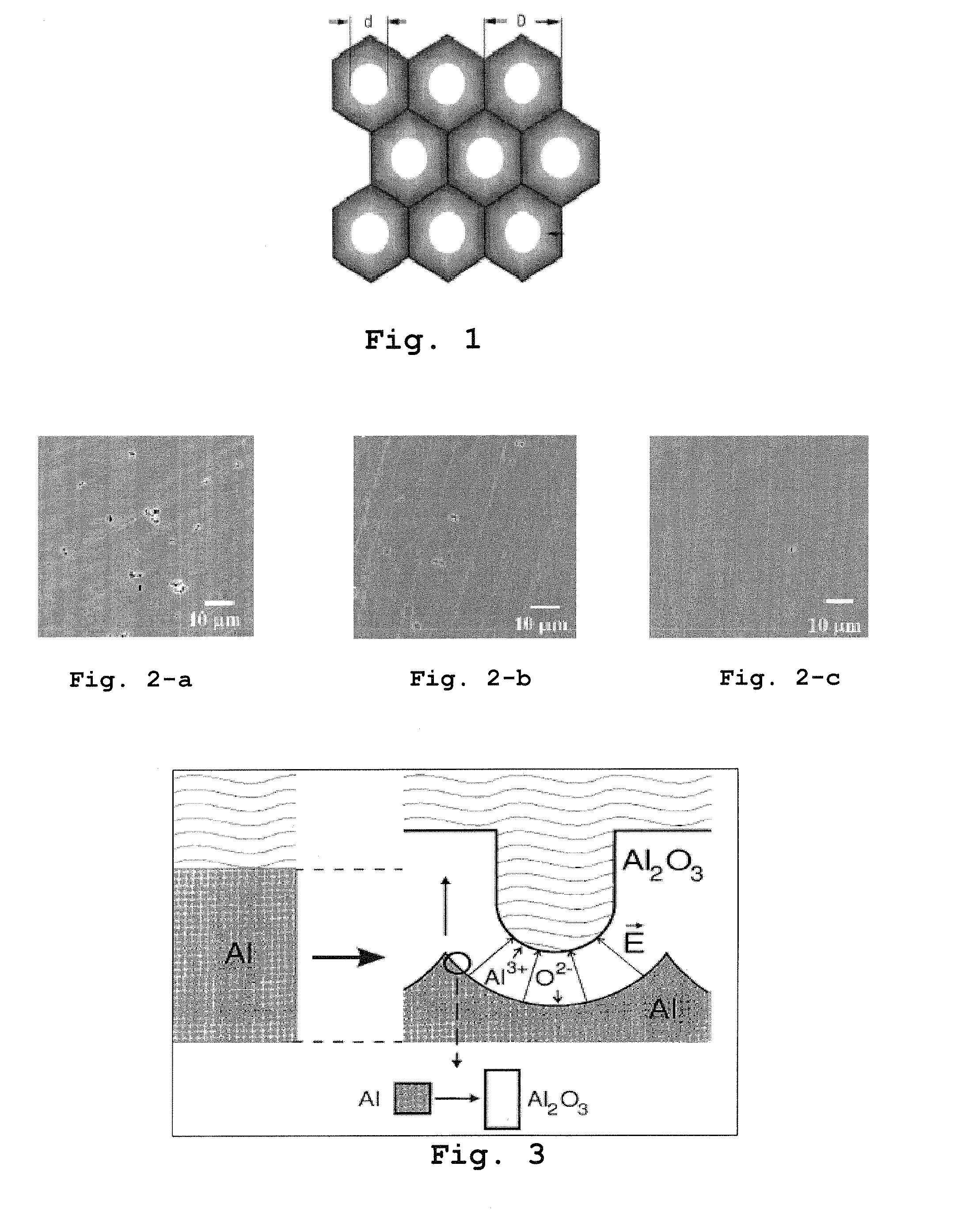

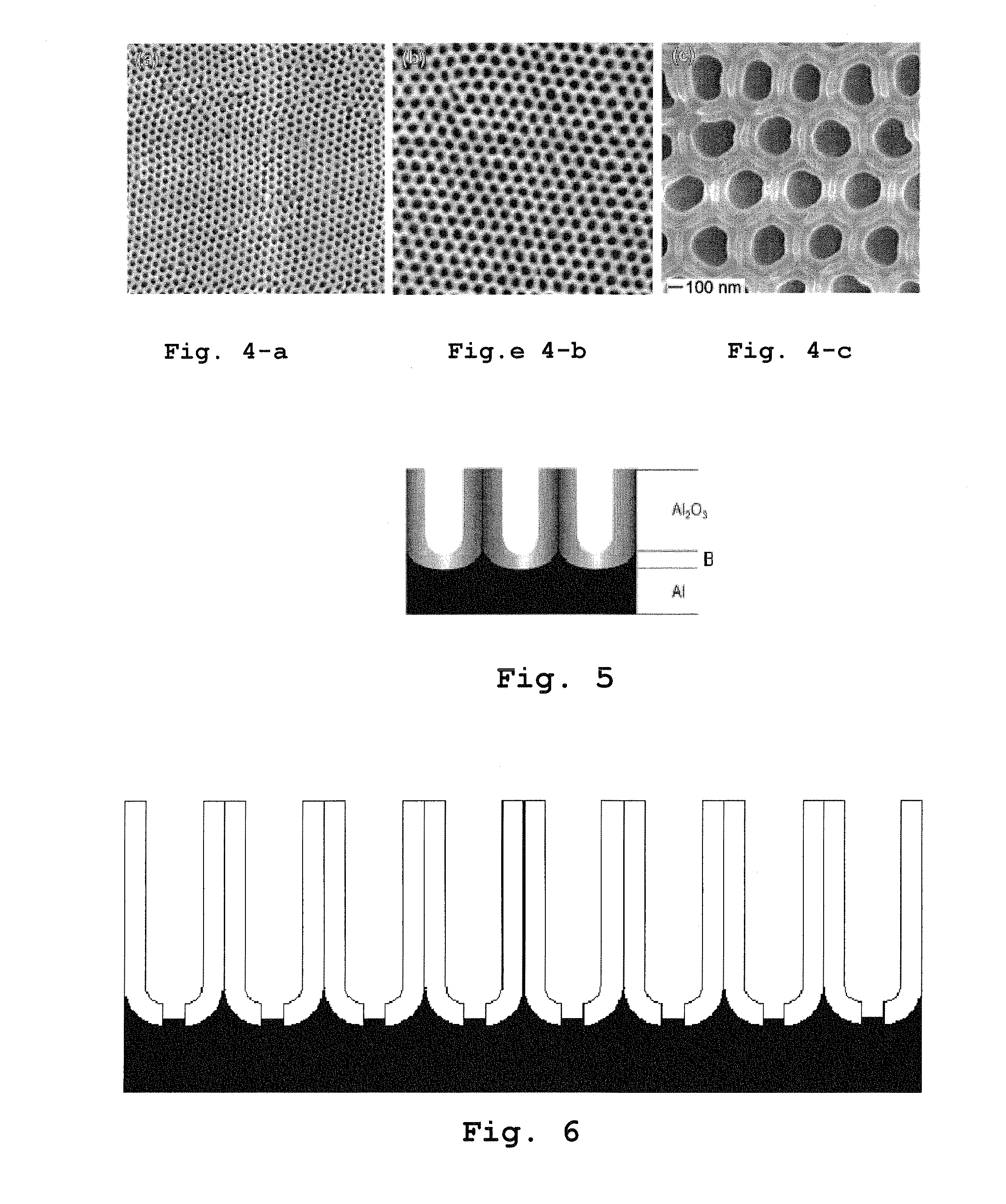

Preparation of the Oxidized Nanostructure Suitable for Metal Electro-Deposition

[0051]Aluminum sheets having the size of 7×4 cm and thickness of 0.5 mm were used as the substrates during the experimental procedure. The substrates used for this purpose were supplied from Assan Alüminyum San. A.S.-Istanbul Turkiye, as 1050 series aluminum sheets which have the following specific composition;

AlFeSiCuMgMnZnVTiOthers99.50.40.250.050.050.050.050.050.030.03minmaxmaxmaxmaxmaxmaxmaxmaxmax

[0052]Aluminum sheets are subjected to the cleaning steps prior to the anodization procedure. Sheets are immersed into a 40 g / L NaOH solution at 55° C. for 2 minutes and then washed with purified water. Samples are polished by way of immersing the same into a 15% (by volume) HNO3 solution for 30 seconds and washed again with distilled water. Anodization experiments were conducted twice with a 72V-12 A DC source in a double walled cooling bath wherein the temperature was controlled with a thermostat having ±0....

example 2

Metal Electro-Deposition and Manufacturing of Nanowires

[0056]The porous nanostructure which was made electronically conductive for 60 seconds in the previous example was subjected to an electrolytic metal deposition step wherein said structure was utilized as the cathode and Ni was utilized as the anode electrode. Electrolytic solution bath was containing 300 g / L NiSO4 and 45 g / L H3BO3 and said solution was heated to 50° C. before starting the electrolytic process. Two pieces of nanostructure sheets were used in the process in order to observe the amount of metal deposition depending on the current density. One of the pieces was subjected to 2 A / dm3 and the other one was subjected to 0.2 A / dm2 current densities for this purpose. Pieces were washed right after the electrolytic process and analyzed with Scanning Electron Microscope. Results are shown in FIGS. 10-a and 10-b wherein the nanowires formed in 2 A / dm2 current density and the nanowires formed in 0.2 A / dm2 current density are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com