Zinc oxide nanoparticle preparation method based on silk fibroin bio-template regulation

A technology of zinc oxide nano and silk fibroin, which is applied in the field of biomedical materials, can solve the problems such as difficult to control the particle size and shape of zinc oxide nanoparticles, and achieve the effects of low cost, improved antibacterial performance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

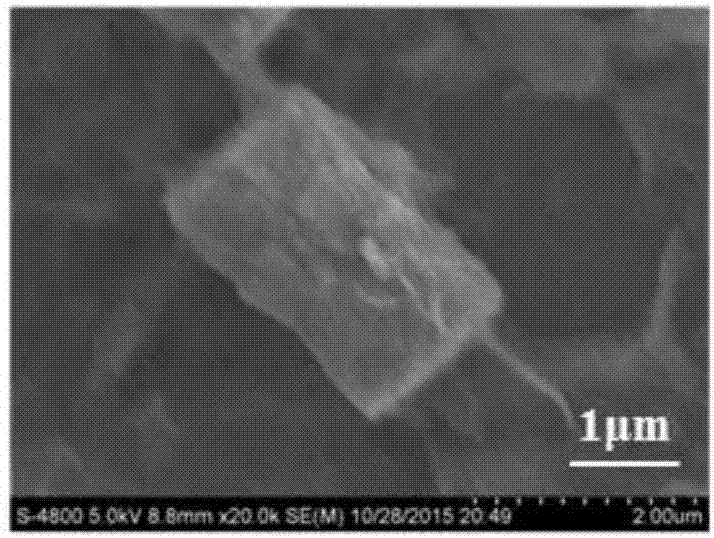

Embodiment 1

[0040] S1, dissolving silkworm cocoons after degumming to prepare silk fibroin aqueous solution; specifically:

[0041] S11, cut silkworm cocoons into pieces, weigh 5g of silkworm cocoons, and then boil them in 2L of 0.02mol / L Na2CO3 solution for 30min to remove sericin on the silk surface. After boiling, wash the degummed silk fibroin several times with deionized water and dry it naturally;

[0042] S12, dissolving the silk fibroin prepared in step S11 in 9 mol of LiBr at 60°C for about 4 hours, after the silk fibroin is completely dissolved, dialyze with a dialysis membrane for 72 hours to obtain silk with a mass volume fraction of 6-7w / v% An aqueous protein solution, storing the silk fibroin aqueous solution in a refrigerator at 4°C for use;

[0043] S2, prepare a solution with a concentration of 0.01mol / L hexamethylenetetramethylamine and a concentration of 0.01mol / L zinc nitrate, each take 19ml and mix in equal volumes to obtain 38mL;

[0044] S3, adding the silk fibroi...

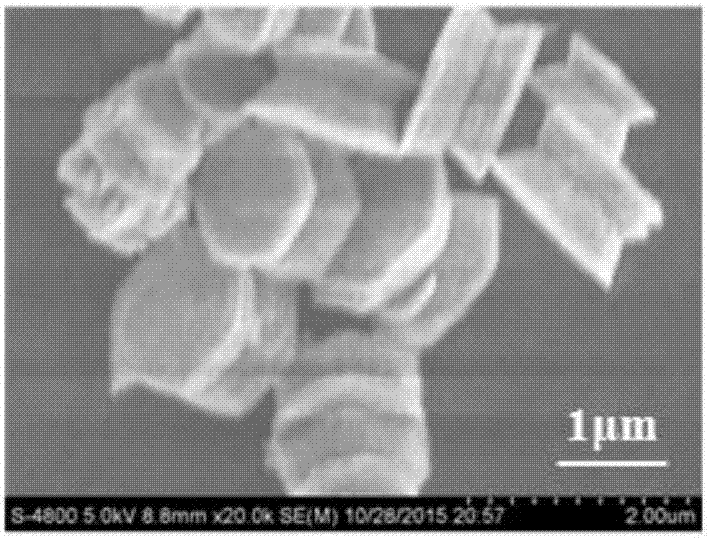

Embodiment 2

[0048] S1, dissolving silkworm cocoons after degumming to prepare silk fibroin aqueous solution; specifically:

[0049] S11, cut silkworm cocoons into pieces, weigh 5g of silkworm cocoons, and then boil them in 2L of 0.02mol / L Na2CO3 solution for 30min to remove sericin on the silk surface. After boiling, wash the degummed silk fibroin several times with deionized water and dry it naturally;

[0050]S12, dissolving the silk fibroin prepared in step S11 in 9 mol of LiBr at 60°C for about 4 hours, after the silk fibroin is completely dissolved, dialyze with a dialysis membrane for 72 hours to obtain silk with a mass volume fraction of 6-7w / v% An aqueous protein solution, storing the silk fibroin aqueous solution in a refrigerator at 4°C for use;

[0051] S2, prepare a solution with a concentration of 0.01mol / L hexamethylenetetramethylamine and a concentration of 0.01mol / L zinc nitrate, each take 19ml and mix in equal volumes to obtain 38mL;

[0052] S3, adding the silk fibroin...

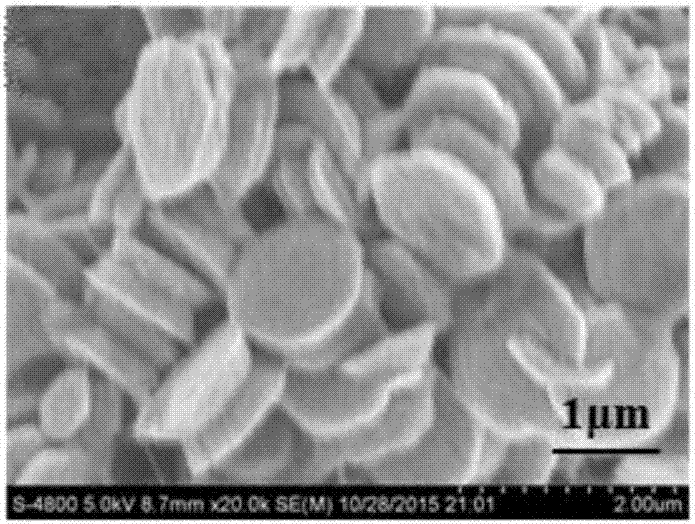

Embodiment 3

[0056] S1, dissolving silkworm cocoons after degumming to prepare silk fibroin aqueous solution; specifically:

[0057] S11, cut silkworm cocoons into pieces, weigh 5g of silkworm cocoons, and then boil them in 2L of 0.02mol / L Na2CO3 solution for 30min to remove sericin on the silk surface. After boiling, wash the degummed silk fibroin several times with deionized water and dry it naturally;

[0058] S12, dissolving the silk fibroin prepared in step S11 in 9 mol of LiBr at 60°C for about 4 hours, after the silk fibroin is completely dissolved, dialyze with a dialysis membrane for 72 hours to obtain silk with a mass volume fraction of 6-7w / v% An aqueous protein solution, storing the silk fibroin aqueous solution in a refrigerator at 4°C for use;

[0059] S2, prepare a solution with a concentration of 0.01mol / L hexamethylenetetramethylamine and a concentration of 0.01mol / L zinc nitrate, each take 19ml and mix in equal volumes to obtain 38mL;

[0060] S3, adding the silk fibroi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com