Basic zincic acid salt plating liquor, its electroplating method and long steel-pipe with electroplated zinc nickel alloy

A technology of electroplating zinc-nickel and zincate, which is applied in the field of alloy electroplating, which can solve the problems of uneven coating and poor coating, and achieve the effect of uniform coating, no missing plating, and low corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: The plated piece is a Φ15×100 mm steel pipe with one end closed.

[0039] According to the formulation of the plating solution of the present invention, the cathode current density is 2 amps / dm2, and electroplating is performed at 25° C. for 30 minutes. The depth of the inner coating of the test steel pipe is 15.3 to 16 mm, which shows that the dispersion ability of the plating solution is very good.

Embodiment 2

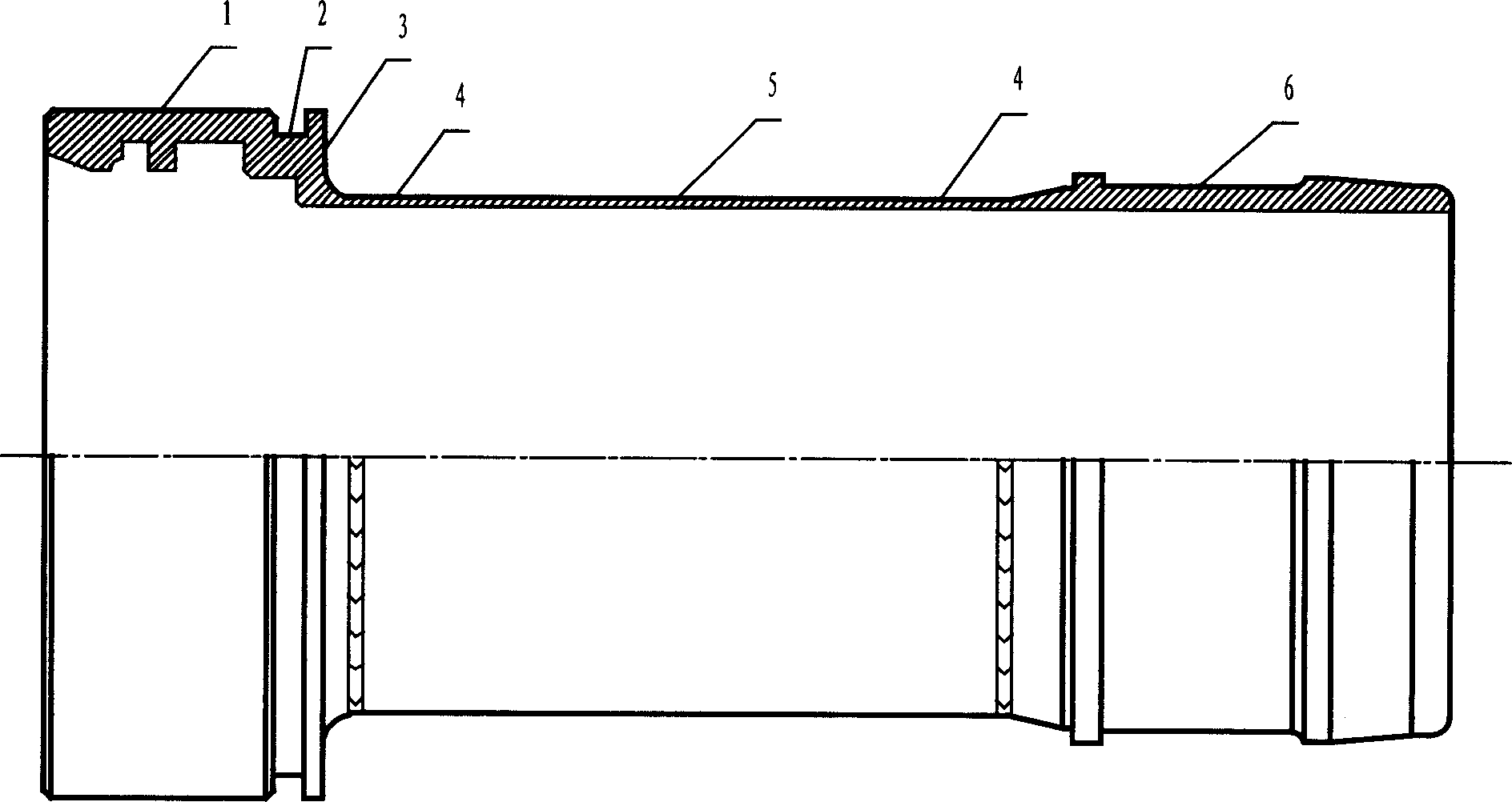

[0040] Embodiment 2: The plated part is a socket steel pipe with a length of 6 meters and a diameter of 152 mm, and the ratio of the wall thickness of the socket to the wall thickness of the pipe body is greater than 6.

[0041] According to the plating solution formula and process operating conditions of the present invention, and the auxiliary anode is set at the appropriate position of the steel pipe, the outer surface of the obtained coating is bright stainless steel, the coating is uniform, the nickel content in the coating is about 10%, and its corrosion resistance is the same thickness 2.8 times that of zinc coating, the hardness is 1.9 times that of zinc coating of the same thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com