Melt method for growing sosoloid monocrystal of lead lead-titanate niobium-zincate

A lead niobate, solid solution technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of difficulty in obtaining high-quality solid solution single crystals, large changes in the supersaturation of the growth solution, and poor repeatability of the crystal growth process, etc. problems, to achieve the effect of reducing the generation of inclusions, good crystal integrity, and easy control of growth process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

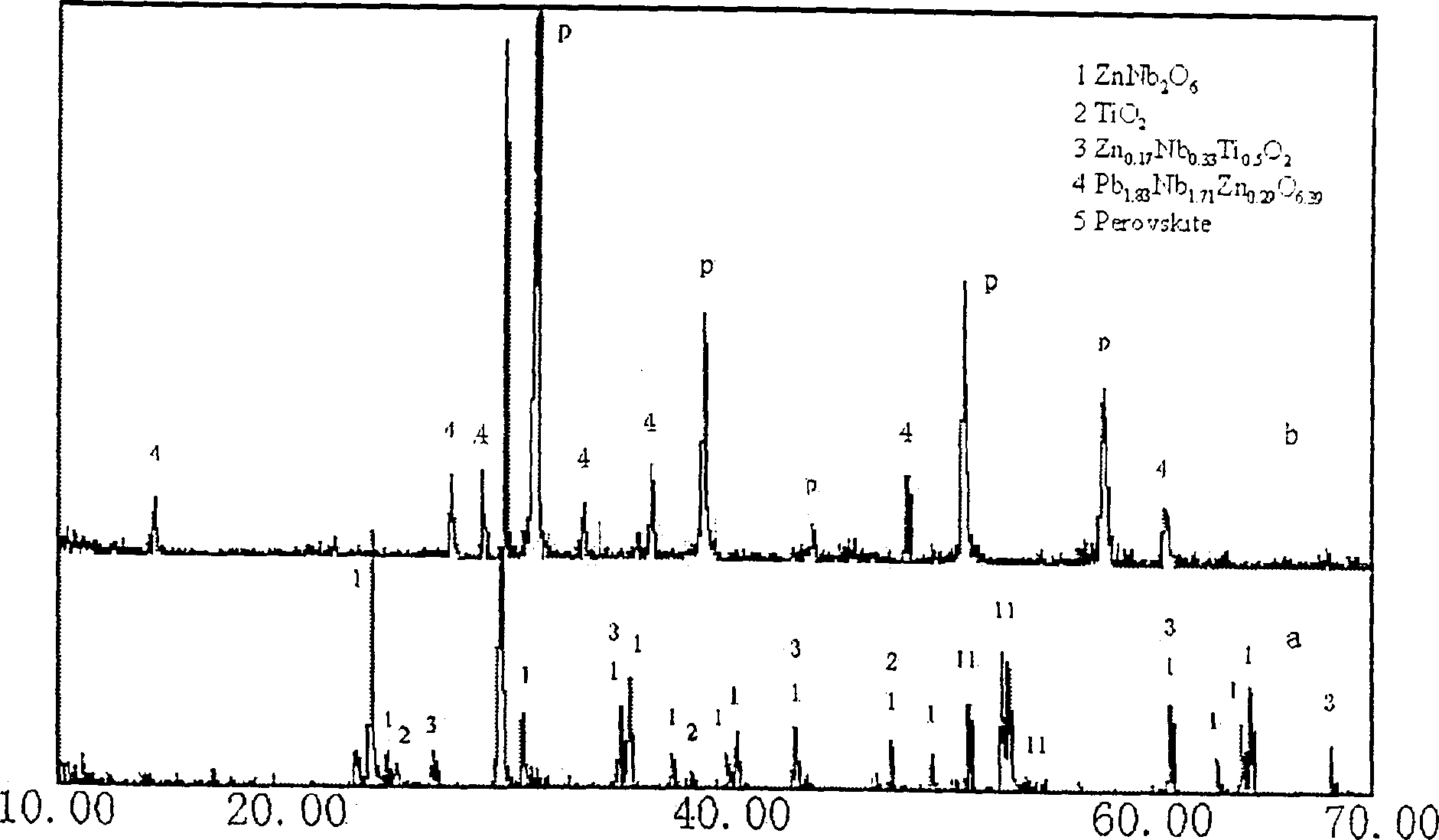

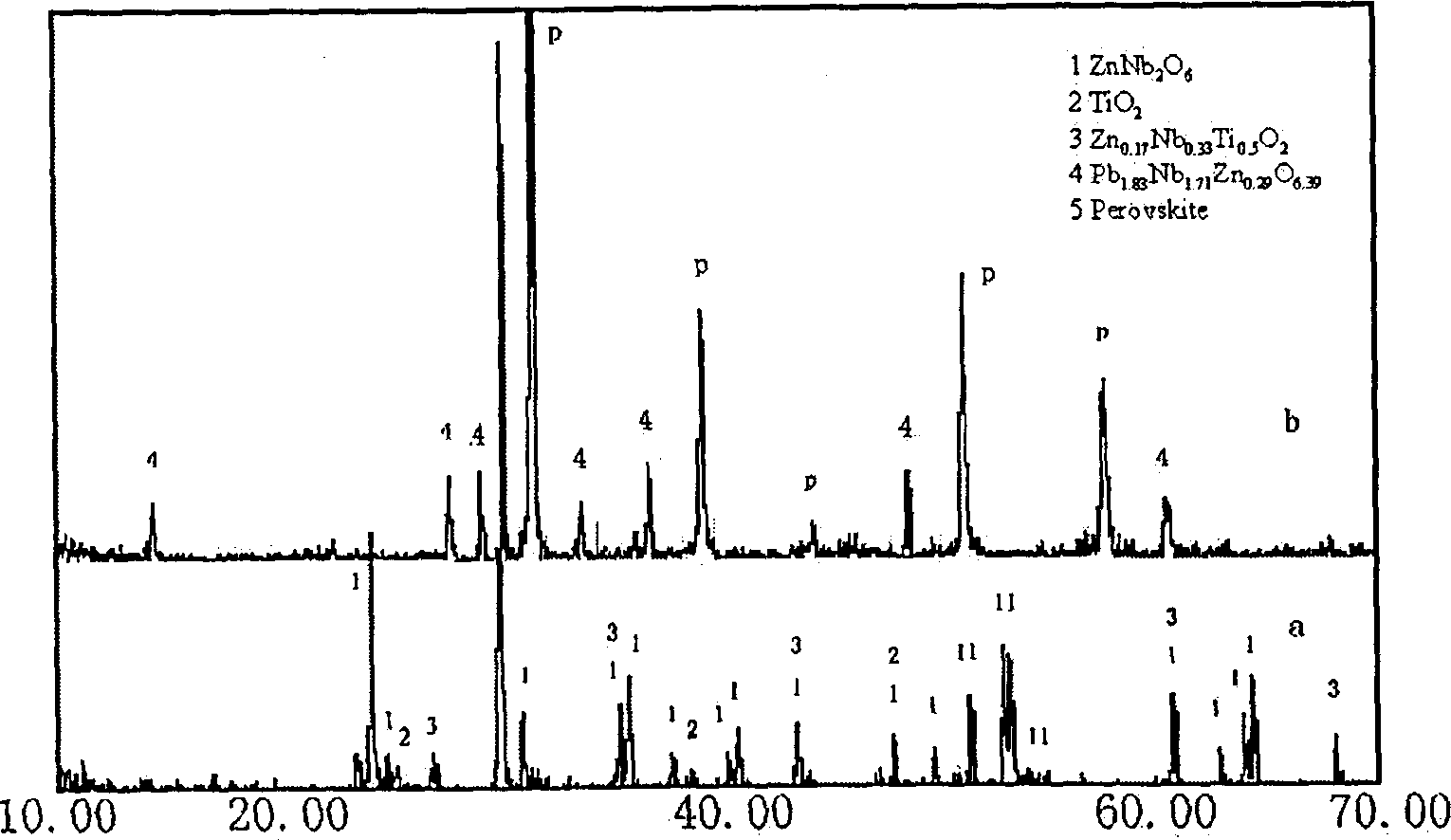

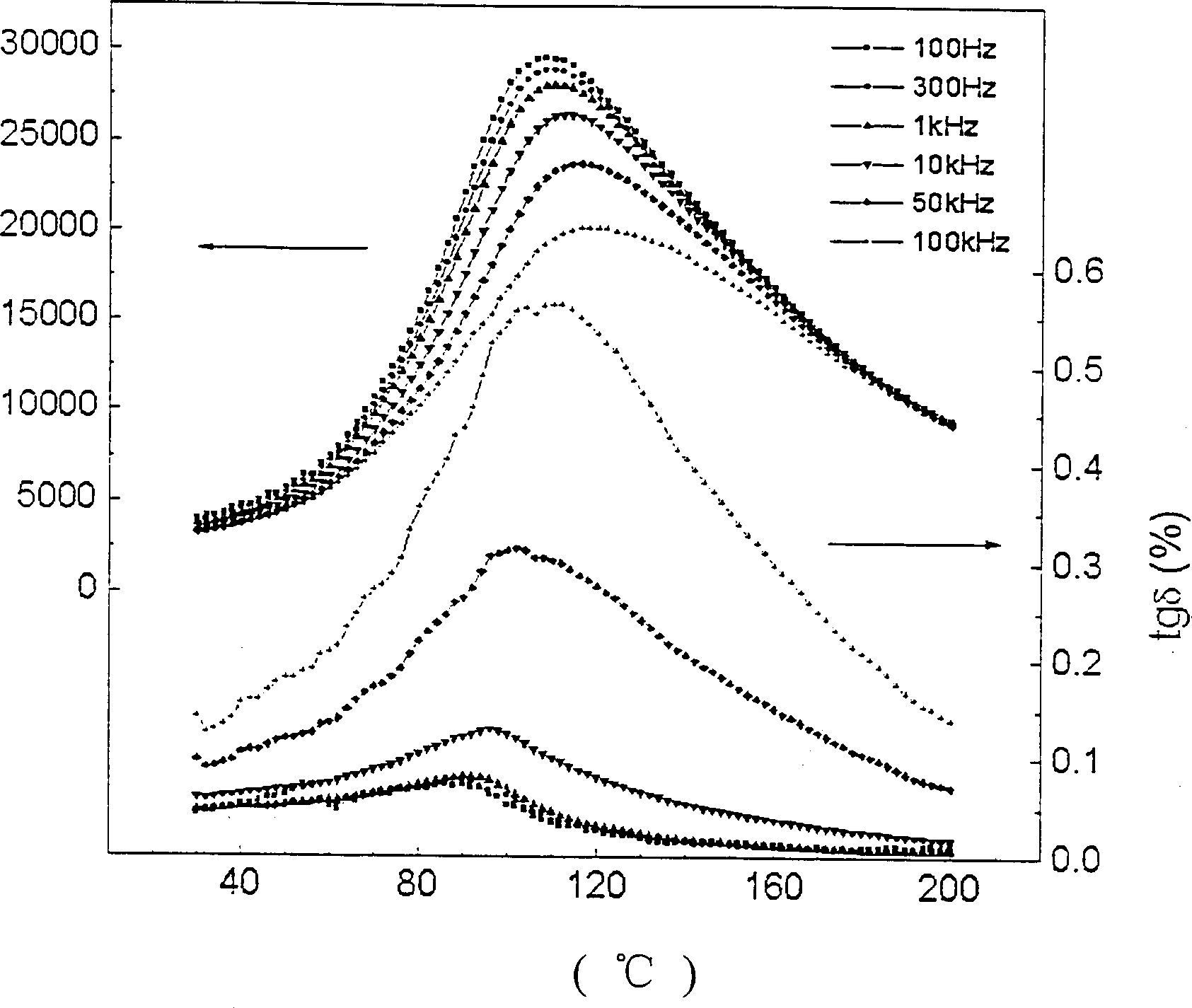

Embodiment 1

[0029] Obtain the raw material of crystal growth with B position presynthesis method, and growth raw material is according to chemical formula (1-x)Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -xPbTiO 3 X=0.09 ratio. High-purity zinc oxide, niobium pentoxide and titanium dioxide powder are mixed evenly by wet ball milling. The obtained powder is dried and placed in a covered platinum crucible for heat treatment at 950°C for 1.5 hours. The main ingredient is ferroniobium Ore structure zinc niobate (ZnNb 2 o 6 ). The above-mentioned powder is added with lead oxide in a metered ratio, mixed evenly by wet ball milling, the obtained powder is dried, placed in a covered platinum firing crucible, and heat-treated at 750°C for 1.5 hours. The main component of the obtained pretreated raw material is perovskite structure lead niobate zincate lead titanate solid solution 0.91Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.09PbTiO 3 . Press the above-mentioned powder into blocks by cold isostatic pressing. However, the m...

Embodiment 2

[0031] X = 0.15, first configure zinc niobate whose main component is niobite structure, treat at 980°C for 1.2 hours, then add PbO, treat at 700°C for 2 hours, then grow along the (110) plane, with a temperature gradient of 60°C / cm, the temperature of the growth furnace was controlled at 1400°C, and the cooling rate was 10°C / h, and the rest were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com