Method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid

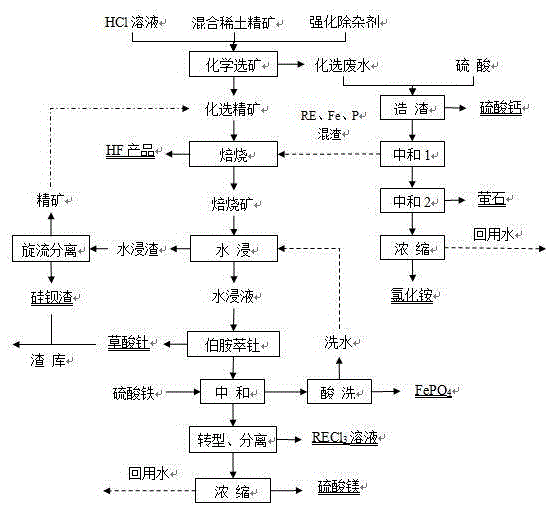

A technology of mixing rare earth and concentrated sulfuric acid, applied in the direction of improving process efficiency, etc., can solve the problems of large amount of radioactive waste residue, uncontinuous process, uncontinuous roasting, etc., achieve dissolution rate and dissolution rate increase, and high efficiency of the dissolution process The effects of chemicalization and production reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix 100g of mixed rare earth concentrate (48.68% by mass of REO, 13.2% by mass of CaO), hydrochloric acid solution with a concentration of 3.5mol / L of hydrogen ion species, and concentrated sulfuric acid solution. The solid-to-liquid volume ratio of mixed rare earth concentrate and hydrochloric acid solution is 1:8; add 15 grams of concentrated sulfuric acid to every liter of hydrochloric acid solution. Stir and dissolve for 180 minutes under the condition of 93°C≤temperature≤95°C. After the dissolution, 67.6 g of chemical separation concentrate and chemical separation waste water with a mass percentage of REO of 69.85% and a mass percentage of CaO of 0.83% were obtained by filtration.

[0029] The chemical separation concentrate and concentrated sulfuric acid are mixed according to the weight ratio of 1:1.4, and roasted in a muffle furnace at 280°C for 1.5 hours. The roasted ore was mixed with water and leached for 1 hour, and the water leaching liquid and water leach...

Embodiment 2

[0039] Mix 100g of mixed rare earth concentrate (58.32% by mass of REO, 13.2% by mass of CaO), hydrochloric acid solution with a concentration of 2.5mol / L of hydrogen ion species, and concentrated sulfuric acid solution. The solid-to-liquid volume ratio of mixed rare earth concentrate and hydrochloric acid solution is 1:5; add 8g of concentrated sulfuric acid to every liter of hydrochloric acid solution. Stir and dissolve for 150 minutes under the condition of 93°C≤temperature≤95°C. After the dissolution, 76.3 g of chemical separation concentrate and chemical separation wastewater with a mass percentage of REO of 74.5% and a mass percentage of CaO of 0.51% were obtained by filtration.

[0040] The chemical separation concentrate and concentrated sulfuric acid are mixed according to the weight ratio of 1:1.2, and roasted in a muffle furnace at 250°C for 3 hours. The roasted ore was mixed with water and leached for 40 minutes, filtered to obtain the water leaching liquid and wa...

Embodiment 3

[0043] Mix 100g of mixed rare earth concentrate (67.96% by mass of REO, 4.55% by mass of CaO), hydrochloric acid solution with a concentration of 1.3mol / L of hydrogen ion substance, and concentrated sulfuric acid solution. The solid-to-liquid volume ratio of mixed rare earth concentrate and hydrochloric acid solution is 1:4; 5g of concentrated sulfuric acid is added to each liter of hydrochloric acid solution. Stir and dissolve at 85°C for 120 min. After the dissolution, 84.1 g of chemical separation concentrate and chemical separation waste water with a mass percentage of REO of 78.4% and a mass percentage of CaO of 1.32% were obtained by filtration.

[0044] The chemical separation concentrate and concentrated sulfuric acid are mixed according to the weight ratio of 1:1.4, and roasted in a muffle furnace at 250°C for 4.5 hours. The roasted ore was mixed with water and leached for 30 minutes, filtered to obtain the water leaching liquid and water leaching residue, the REO co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com