Preparation method for taxus chinensis extractive and application of taxus chinensis extractive

A Taxus chinensis extract and Taxus chinensis technology are applied in the directions of drug combinations, medical raw materials derived from gymnosperm subphylum, metabolic diseases, etc., and can solve the problems such as the need to improve the dissolution rate, so as to accelerate the extraction speed, improve the dissolution rate, reduce the The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

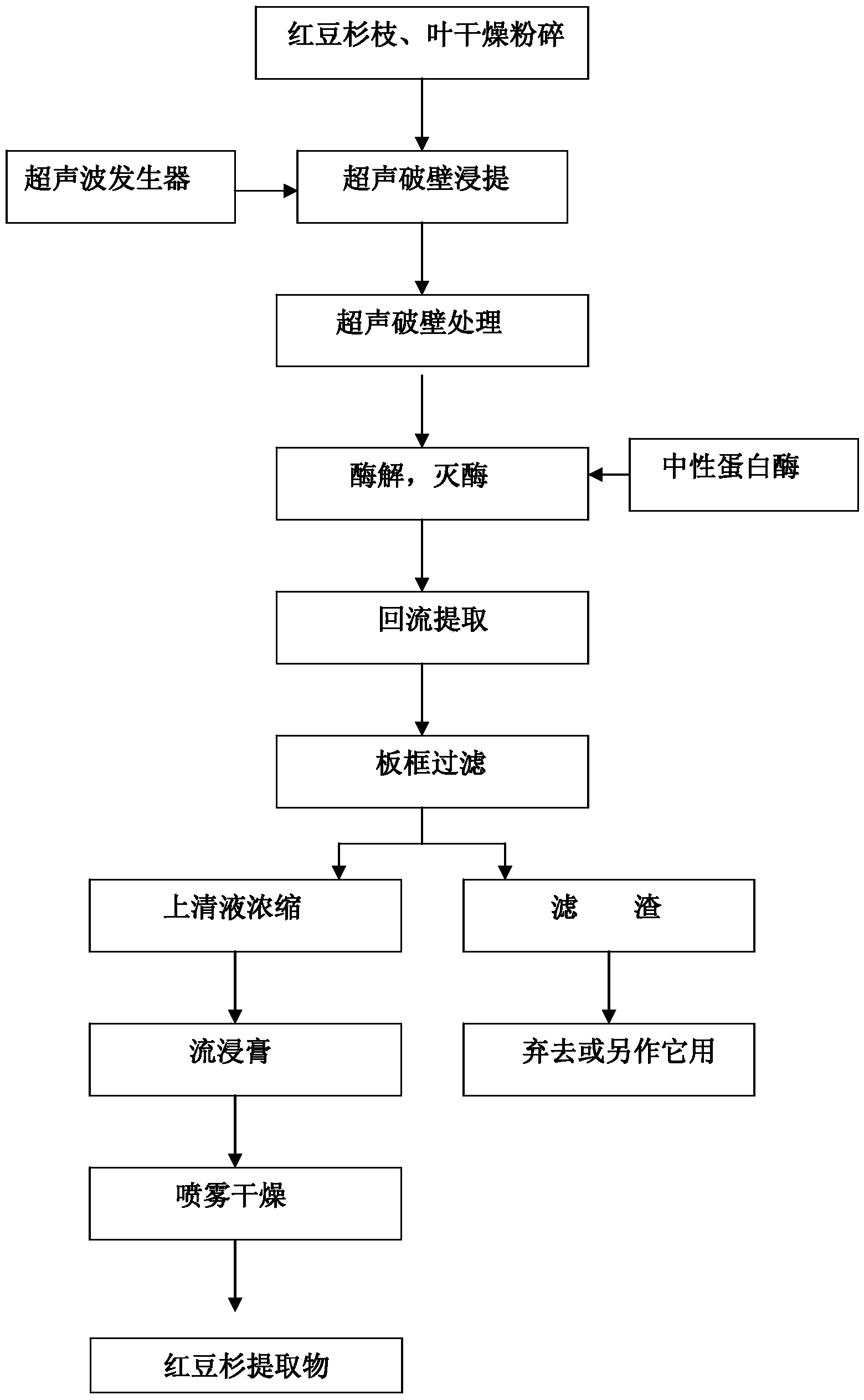

[0030] The preparation method of the yew extract of the present embodiment, comprises the steps:

[0031] (1) Prepare the raw material of yew, dry and crush the branches and leaves of yew, pass through an 80-mesh sieve, and the sieve is the raw material of yew, which is set aside.

[0032] (2) Ultrasonic wall breaking treatment, take the undersieve, that is, 10 kg of yew raw material, put it into an ultrasonic wall breaking extraction tank, add 15 times the weight of the yew raw material soaking agent—water, stir and soak at 50 ° C for 1 hour; Use an ultrasonic generator for ultrasonic wall breaking treatment, the power of the ultrasonic generator is 15-30KW, such as 20KW, the frequency is 20-25KHz, such as 23KHz, and the sound intensity is 2W / cm 2 , ultrasonic treatment for 30min to obtain feed liquid.

[0033] (3) enzymatic hydrolysis, the material liquid is transferred to the reaction vessel—that is, in the stirring extraction tank, and neutral protease accounting for 0.3%...

Embodiment 2

[0039] The preparation method of the yew extract of the present embodiment, comprises the steps:

[0040] (1) Prepare the raw material of yew, dry and crush the branches and leaves of yew, pass through an 80-mesh sieve, and the sieve is the raw material of yew, which is set aside.

[0041] (2) Ultrasonic wall breaking treatment, take the undersieve, that is, 10 kg of yew raw material, put it into an ultrasonic wall breaking extraction tank, add 15 times the weight of the yew raw material soaking agent—water, stir and soak at 50 ° C for 1 hour; Use an ultrasonic generator for ultrasonic wall breaking treatment. The power of the ultrasonic generator is 15-30KW, such as 15KW, the frequency is 20-25KHz, such as 20KHz, and the sound intensity is 2W / cm 2 , ultrasonic treatment for 40min to obtain feed liquid.

[0042] (3) enzymatic hydrolysis, the feed liquid is transferred to the reaction vessel—that is, in the stirring extraction tank, and neutral protease accounting for 0.5% of ...

Embodiment 3

[0048] The preparation method of the yew extract of the present embodiment, comprises the steps:

[0049] (1) Prepare the raw material of yew, dry and crush the branches and leaves of yew, pass through an 80-mesh sieve, and the sieve is the raw material of yew, which is set aside.

[0050] (2) Ultrasonic wall breaking treatment, take the undersieve, that is, 10 kg of yew raw material, put it into an ultrasonic wall breaking extraction tank, add 15 times the weight of the yew raw material soaking agent—water, stir and soak at 50 ° C for 1 hour; Use an ultrasonic generator for ultrasonic wall breaking treatment, the power of the ultrasonic generator is 15-30KW, such as 30KW, the frequency is 20-25KHz, such as 25KHz, and the sound intensity is 3W / cm 2 , ultrasonic treatment for 30min to obtain feed liquid.

[0051] (3) enzymatic hydrolysis, the feed liquid is transferred to the reaction vessel—that is, in the stirring extraction tank, and neutral protease accounting for 0.8% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com