Method for manufacturing sintering ore from limonite with high content of crystal water

A technology for sintering ore and limonite, applied in the field of metallurgical sintering, can solve the problems of difficulty in beneficiation of limonite, affecting the consistency of the sintering process, uneven particle size, etc. Pulverization index, the effect of making up for the lack of sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A. The new iron material, fuel and flux required for sintering are transported to the batching bin by the belt conveyor, and the batching is carried out according to the ratio in Table 1:

[0035] Table 1 Ratio of sintered iron raw material, fuel and flux (%)

[0036] Guisha Mine

[0037] Among them, the physical and chemical indicators of SYP sintering synergist are shown in Table 2:

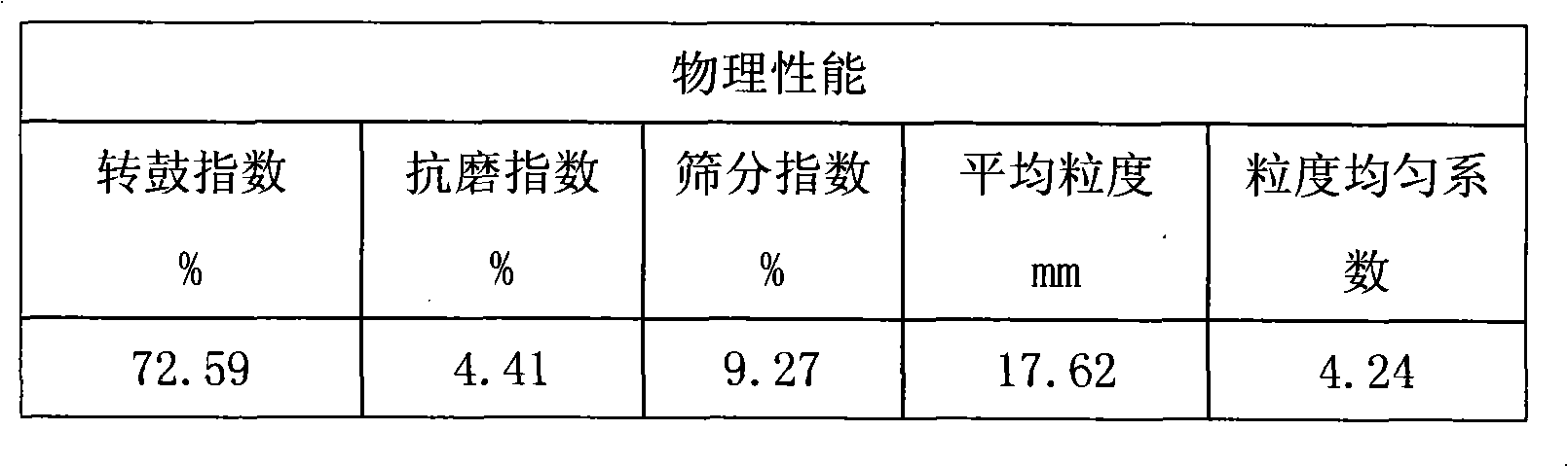

[0038] Table 2

[0039] B 2 o 3

[0040] Note: When moisture is detected, the constant temperature is 102±2°C.

[0041] B. The prepared material is conveyed to the mixing mixer by the belt conveyor, and water is added for primary mixing. The moisture content of the mixture is controlled at 6%, and water is added for secondary mixing, and the moisture content is controlled at 7.86%, so that the granulation effect of the mixture is good. , the particle size of 8mm is 13.65%;

[0042]C. The mixed material is then conveyed to the sintering silo by the belt conveyor...

Embodiment 2

[0054] A. Transport the new iron material, fuel and flux required for sintering to the batching bin by the belt conveyor, according to the table According to the ratio of the ingredients, the physical and chemical indicators of the SYP sintering synergist are shown in the table

[0055] surface Ratio of sintered iron raw material, fuel and flux (%)

[0056] Guisha Mine

pink

brown mineral powder

Concentrate powder

1

Concentrate powder

2

the fuel

white clouds

stone

stone

raw stone

Ash

SYP

Return to mine

31.0

5.5

20.3

20.1

5.1

4.2

3.8

4.0

0.03

5.97

[0057] surface

[0058] B 2 o 3

%

MnO 2

%

moor

moisture

%

More than 40 mesh

%

10.01

3.89

1.9

≤5

≤15

[0059] Note: When moisture is detected, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic susceptibility | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com