Microwave roasting dry type wind magnetic selection method for hematite powder

A technology of hematite powder and microwave roasting, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

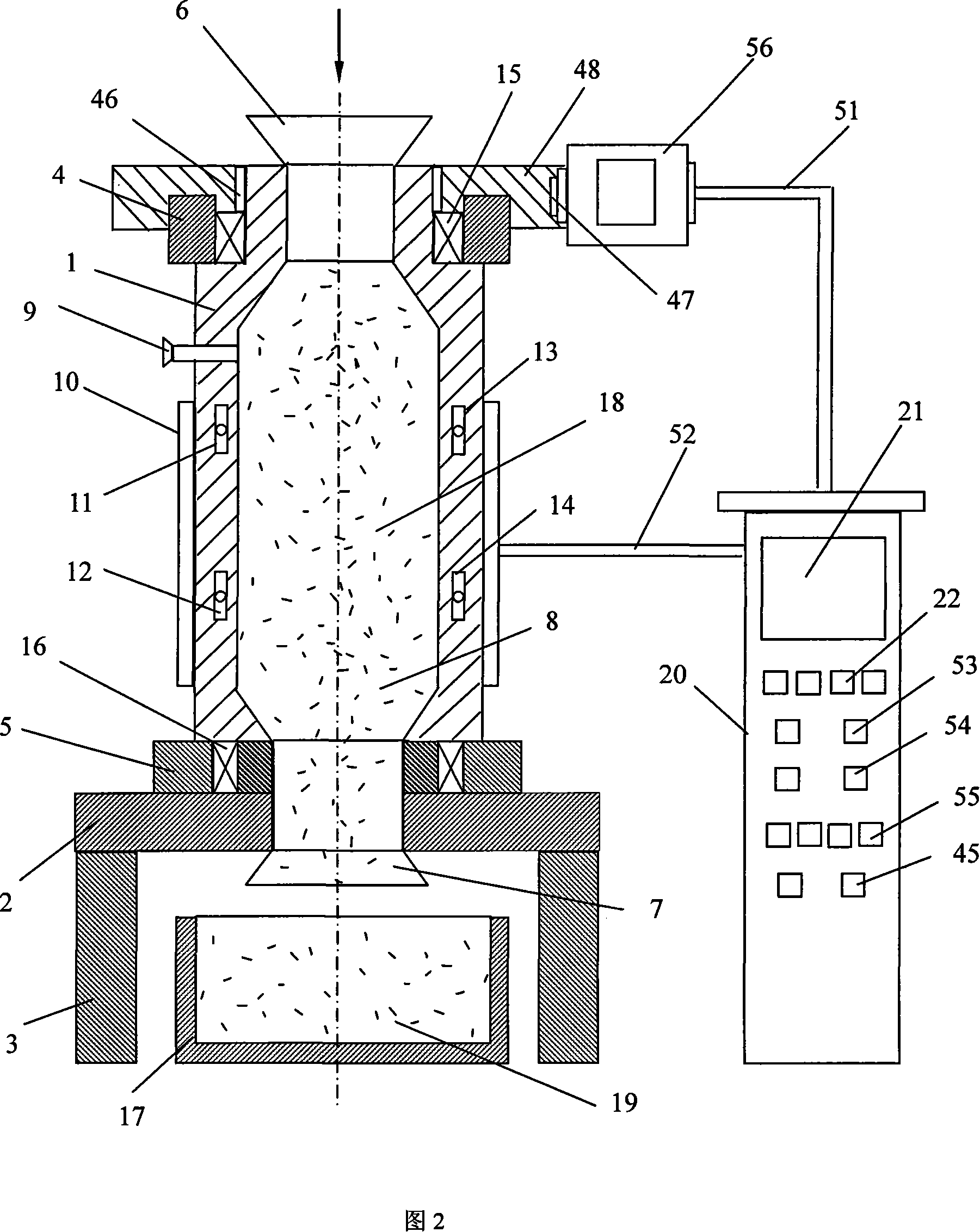

[0088] The present invention will be further described below in conjunction with accompanying drawing:

[0089] As shown in Figure 1, it is a flow chart of the preparation process, which is the whole process of microwave oven roasting and magnetic separation of hematite powder. From the raw material to storage, it must be operated strictly according to the procedure.

[0090] Hematite powder and anthracite powder, the chemical raw materials used in the preparation, are determined according to the preset quantity ratio, and can be calculated according to this ratio.

[0091] Hematite powder ferric oxide Fe used in preparation 2 o 3 > 35%, ferrous TFe content > 24%, impurity content < 15%, impurities are removed in the process of microwave roasting and wind magnetic separation purification.

[0092] The crushing, fine grinding, and sieving of raw materials should be carried out with a mill respectively, and the particle size of the fine powder should be controlled to be 0.1-0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com