Ultra-high performance concrete mixed with hybrid fibers

An ultra-high performance, hybrid fiber technology, applied in the field of building materials, can solve the problems of reducing the durability of concrete, microcracks, and restricting the application and development of ultra-high performance concrete, so as to improve mechanical properties, good economic and social benefits, and good The effect of volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

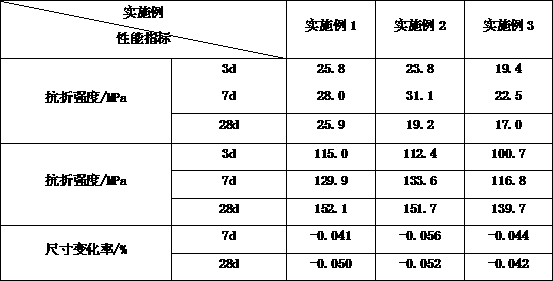

[0064] Example 1, a kind of ultra-high performance concrete mixed with mixed fibers, according to 52.5 grade ordinary Portland cement 100, silica fume 3, floating pearl fly ash 4, slag powder 15, HP-CSA1, quartz sand 60, limonite 15 ore sand, 5 titanium alloy sand, 0.2 polycarboxylate water reducing agent, 0.05 defoamer, 20 steel fiber, 50 basalt fiber, 1 cellulose fiber, and 15 water are used to weigh the raw materials. After stirring, the test piece is formed, and the test piece is cured. The curing condition is temperature (15-40) o C water maintenance. The performance test results are shown in Table 1.

Embodiment 2

[0065] Example 2, a kind of ultra-high performance concrete mixed with mixed fibers, according to 42.5 grade ordinary Portland cement 100, silica fume 15, floating pearl fly ash 15, slag powder 35, HP-CSA 10, quartz sand 90, brown Iron ore sand 35, titanium alloy sand 20, sulfamate water reducer 1.20, defoamer 0.03, steel fiber 150, basalt fiber 5, cellulose fiber 4, water 30 weight ratio raw materials. After stirring, the test piece is formed, and the test piece is cured. The curing condition is temperature (15-40) o C Humid air conservation (relative humidity 70%-100%). The performance test results are shown in Table 1.

Embodiment 3

[0067] Table 1

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com