Reverse flotation iron increase and silicon removing method for refractory limonite

A technology of reverse flotation and limonite, which is applied in flotation, solid separation, etc., can solve the problems of high mineral processing cost, high reagent consumption, and low flotation efficiency, and achieve improved mineral processing recovery rate, high economic promotion value, The effect of fewer types of potions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This method is used to carry out reverse flotation desiliconization and iron extraction of limonite in a mining area in Jiangxi. Limonite is the main iron-containing mineral in the mining area. It appears in the form of granular colloidal rings forming a grid structure. The grids or cavities are often filled with iron-containing clay materials. Mainly) output, limonite and quartz are very closely related. Among them, the average geological grade of iron is 37%, and that of quartz is 32%. Grind the ore to -0.074mm and account for 90%, add 3000 g / t (ore) sodium carbonate during the grinding process, add fresh water to a concentration of 10%, stir until fully dispersed, settle and deslim twice, and the pulp after desliming Concentrate to 40%, add sulfuric acid to control the pH value at about 6, add 50-2000 grams / ton (mine) starch or modified starch (see Table 1 for specific dosage and flotation effect) as limonite inhibitor, 200 grams / ton Ton (mine) 1227 is the collecto...

Embodiment 2

[0021] This method was used to desiliconize a limonite in Guangdong by reverse flotation dispersing cationic enhanced slurry. The limonite deposit is a continental sedimentary deposit. The main mineral in the ore is limonite, followed by a small amount of magnetite and siderite. Gangue minerals mainly include quartz, calcite, chlorite and so on. In the raw ore, limonite and siderite are mainly produced in oolitic form, a small amount is in argillaceous form, and magnetite is produced in massive form. The main component of the ore is an average total iron content of 42% to 44%, low phosphorus and sulfur, and a quartz content of 23.34%. The ore is ground to -0.074mm, accounting for 85%. During the grinding process, 2000 g / t (mine) anhydrous sodium carbonate is added. After sedimentation and desliming twice, the pulp is concentrated to 40%, and sulfuric acid is added to adjust the pH to 5-7 , add 10-2500 g / ton (mine) molecular weight polyacrylamide (see Table 1) of about 10000...

Embodiment 3

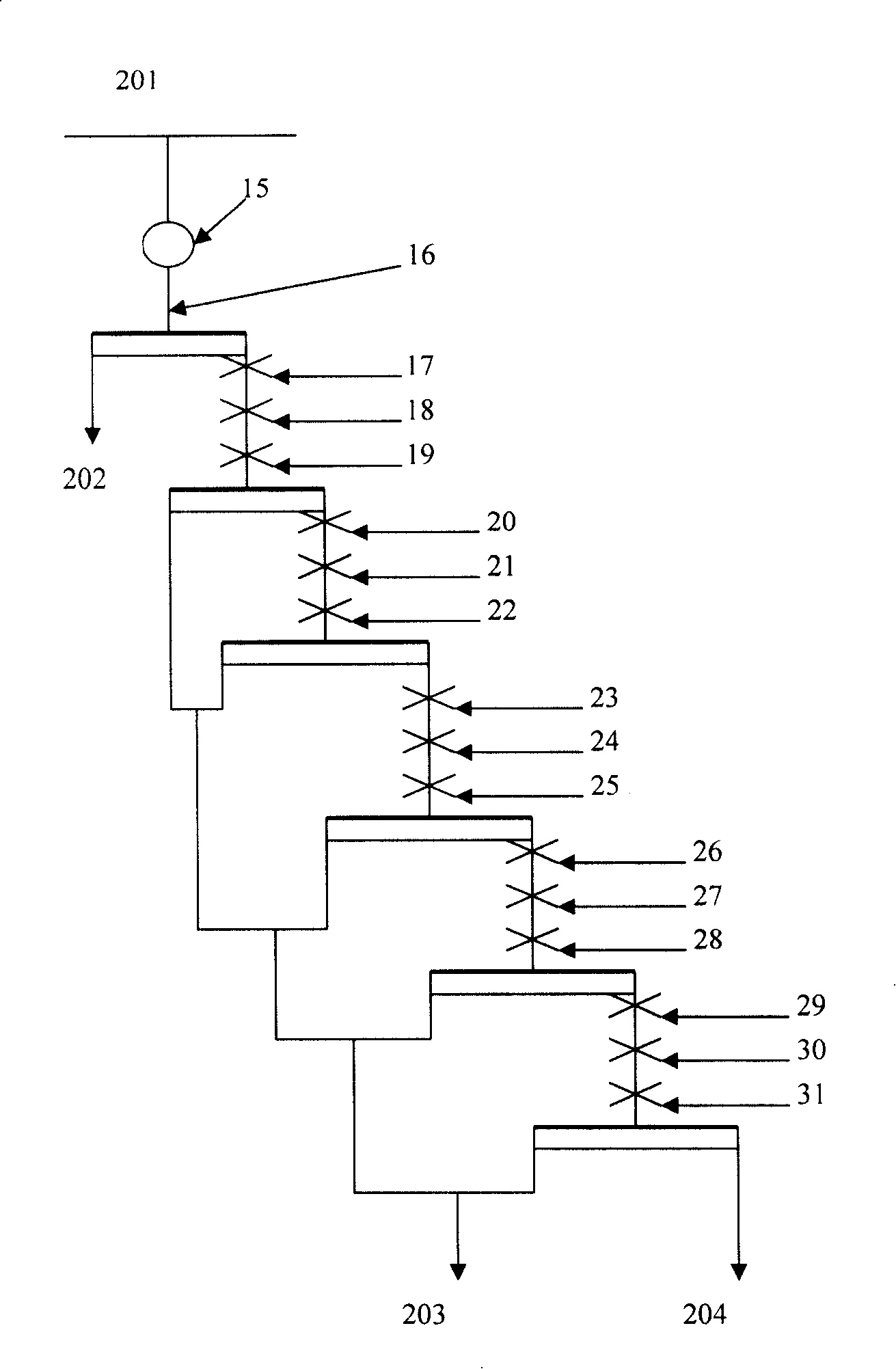

[0023] Using this method, a reverse flotation desiliconization test was carried out on an iron ore in Xinjiang. The main iron mineral of this iron ore is limonite, and the gangue is iron silicate mineral, in which the grade of total iron is 46.5%, SiO 2 22.27%. The ore is crushed to -0.074mm, accounting for 90%. Add 1500 during the grinding process. After desliming, concentrate the pulp to 30%. Add sulfuric acid to adjust the pH to 5-6. Add 50-3000 g / t lignosulfonic acid Sodium is as limonite depressant (specifically see table 1), 200 grams / ton cationic collector 1231, through five reverse flotation (flow chart sees image 3 ), the obtained iron grade is above 52%, SiO 2 For iron ore concentrates with less than 8.21%, the recovery rate of total iron is more than 76%, which is a good indicator.

[0024] The "ton" in the "gram / ton" involved in the present invention refers to raw ore.

[0025] Table 1

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com