Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Reduce flotation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reverse flotation iron increase and silicon removing method for refractory limonite

InactiveCN101234366AImprove mineral processing recovery rateReduce typesFlotationIron increasedRefractory

The invention discloses an reverse flotation iron extracting and desiliconizing method of rebellious limonite. The procedure of the invention is as following: finely grinding, dispersing and desliming ore; adding sulphuric acid to stir the ore power into paste; adding a certain amount of starch or modified starch, lignosulfonate sulphonic acid and their salt and polyacrylamide with the molecular weight about 10,000 or polyacrylamide inhibitory iron-bearing mineral; adopting cation collector quaternary ammonium salt to reverse flotation and separate ore with silicon range or iron ore in a method of adding a little amount of medicine for many times. The reverse flotation iron extracting and desiliconizing method has the advantages of simple process, few medicine agent varieties, able to obtain high grade iron ore concentrate and good effect of raising ore dressing recovery percentage of limonite.

Owner:CENT SOUTH UNIV

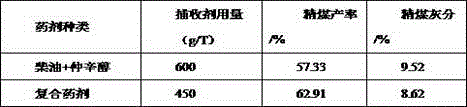

Method for dressing, desilicication and desulfuration of sulfur-containing bauxite

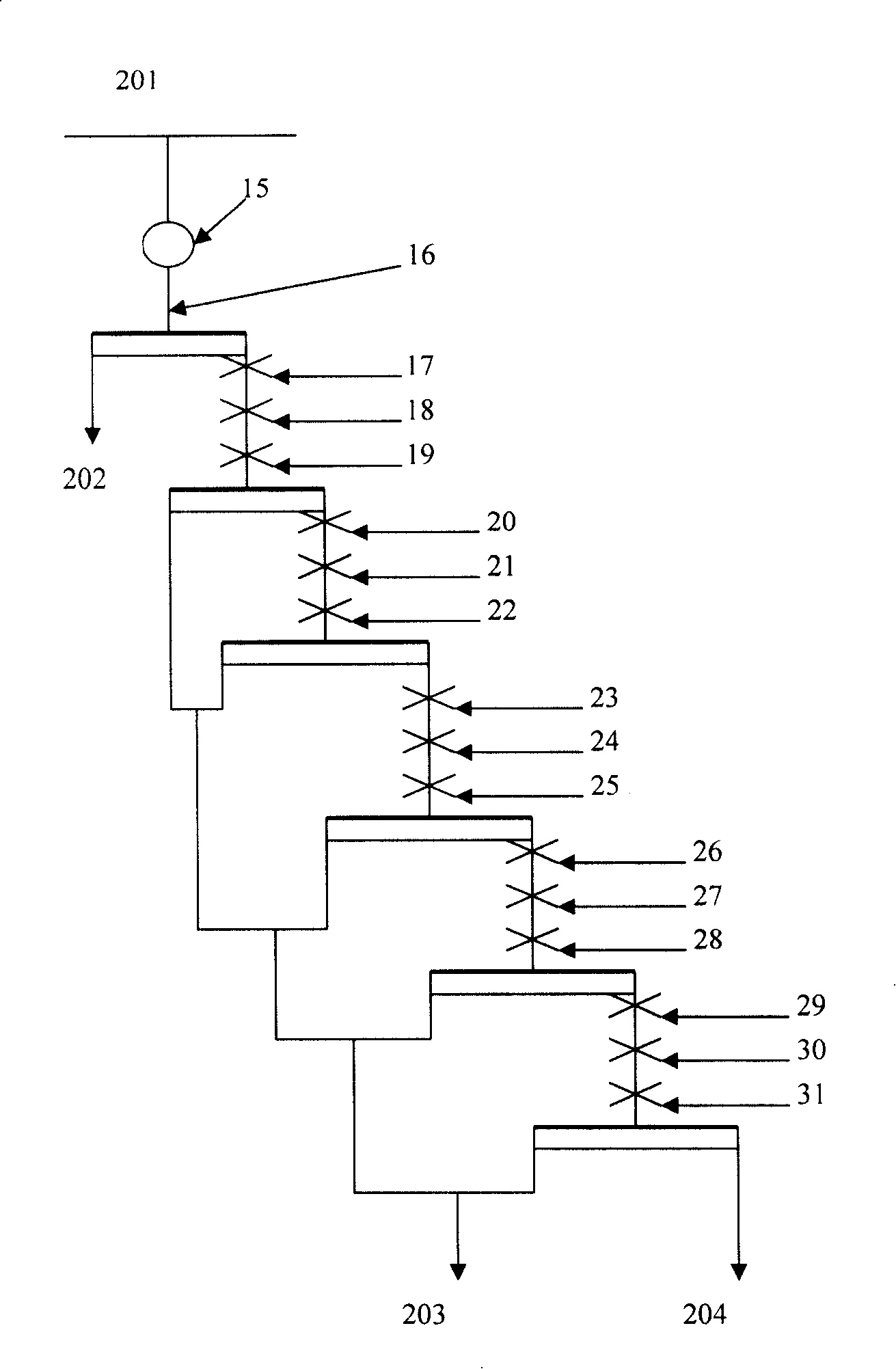

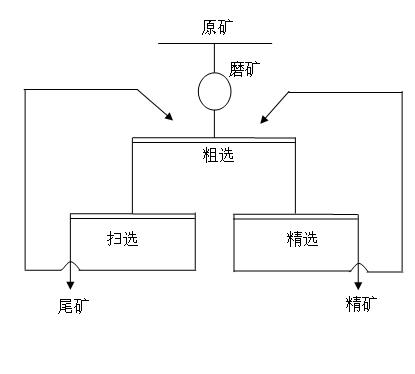

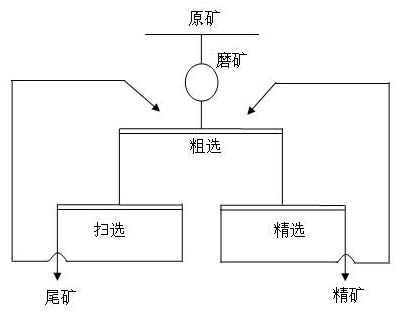

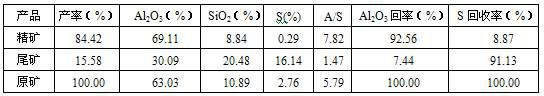

The invention discloses a method for the dressing, desilicication and desulfuration of sulfur-containing bauxite, which relates to a method for the dressing, desilicication and desulfuration of low-quality sulfur-containing bauxite and is characterized in that: a dressing process to mill the sulfur-containing bauxite, regulate the pH to 3 to 6 by using sulfuric acid, add an inhibitor, an activator, a silicate mineral collector and a sulfur-containing gangue collector in turn, stir, perform size mixing and perform flotation; and after flotation, the silicate minerals and sulfur-containing gangue in a major part of the sulfur-containing bauxite are enriched in foam as tailings, and the ore pulp obtained after flotation is used as concentrate. When the method disclosed by the invention is used, the synchronous dressing, desulfuration and desilicication of the sulfur-containing bauxite can be realized quickly. The method has the characteristics of short flow and simple process.

Owner:河南华慧有色工程设计有限公司 +1

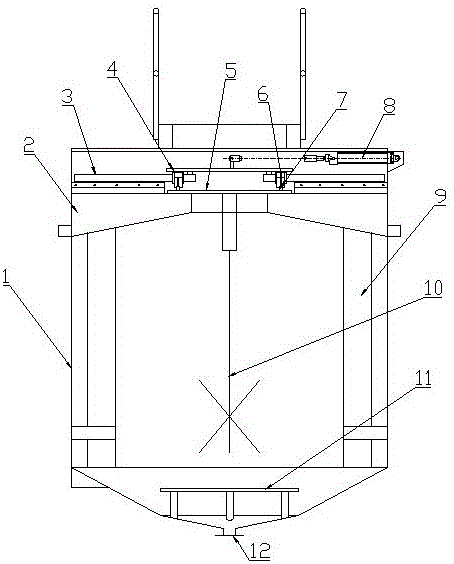

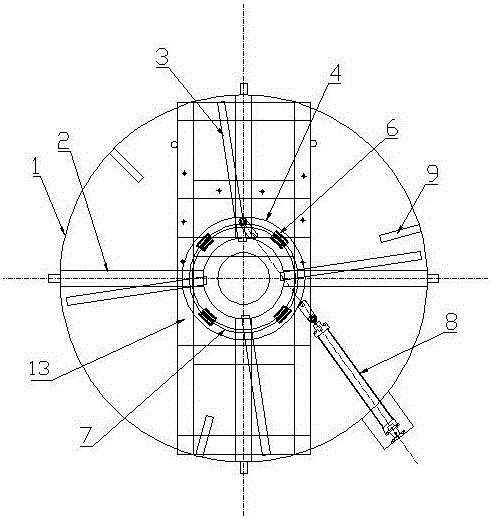

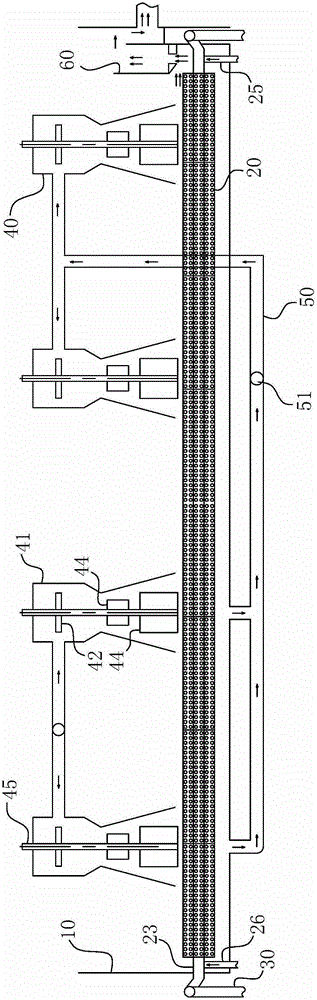

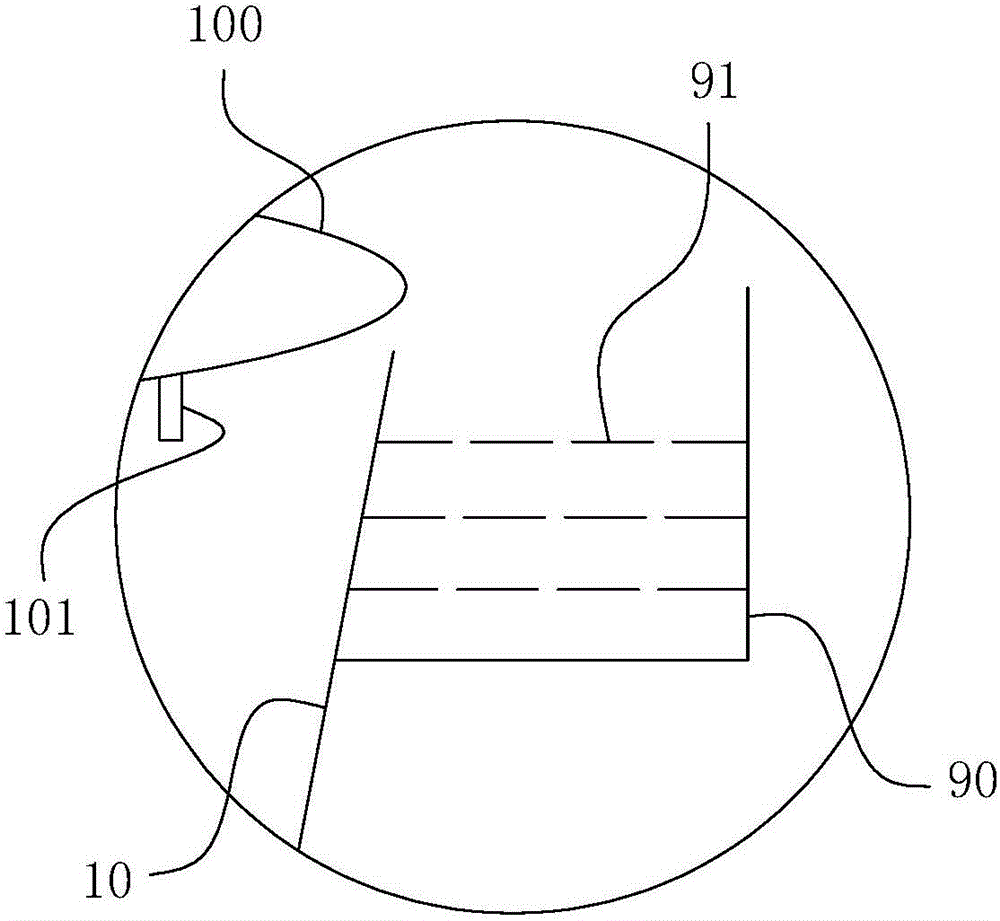

Flotation device and method for removing free carbon in silicon carbide powder

The invention relates to a flotation device and method for removing free carbon in silicon carbide powder. The device comprises a tank and a stirring device. The stirring device is connected with the tank through a fixed frame. A material inlet is arranged at the top of the tank, and a material outlet is arranged at the bottom of the tank. A foam scraping-away device is arranged at the position, between the inner wall of the tank and the stirring device, close to the material inlet, and comprises a foam collecting tank arranged in the radial direction of the tank and a rotary scraping plate matching the foam collecting tank. The outer end of the foam collecting tank is connected with the side wall of the tank, and a foam output opening is formed in the connecting position. The inner end of the foam collecting tank is connected with a fixed seat at the bottom of the fixed frame. A rotary seat is arranged on the fixed seat and provided with the rotary scraping plate. The foam collecting tank and the rotary scraping plate are arranged, so that foam with free carbon on a liquid face is removed smoothly in time, and flotation efficiency is improved. The foam output opening is arranged, so that automatic discharge is achieved. The rotary seat is arranged to avoid dead corner scraping. A power mechanism is arranged, so that the automation degree is high, good stability is achieved, and the flotation efficiency is improved.

Owner:连云港龙塔研磨材料有限公司

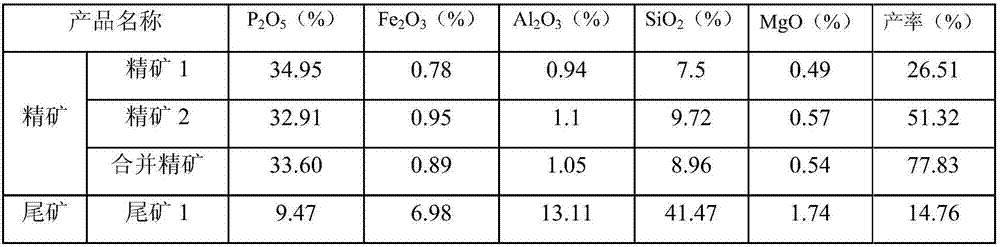

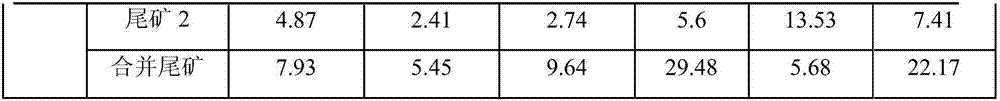

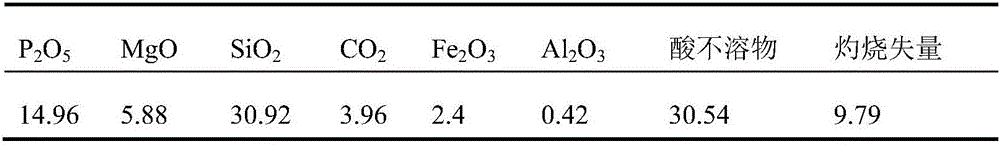

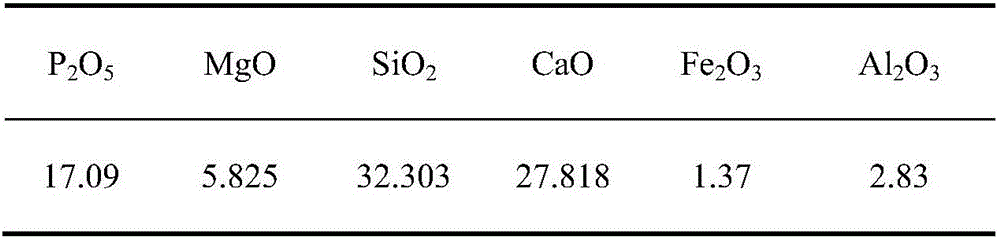

Collophanite ore beneficiation method

The invention belongs to the technical field of ore beneficiation, relates to a collophanite ore beneficiation method, and aims to solve the problems that a conventional collophanite ore beneficiation method is complex in process, high in production cost and poor in the collophanite ore beneficiation effect. The collophanite ore beneficiation method comprises the following steps: pulping collophanite ore to obtain collophanite ore pulp, performing classification on the collophanite ore pulp, performing flotation on the fine-grained ore pulp and performing solid-liquid separation on the concentrate ore pulp. The collophanite ore beneficiation method has the benefits as follows: by mainly controlling the grinding size of the collophanite ore, separating the coarse-grained ore pulp from the fine-grained ore pulp and performing flotation treatment on the fine-grained ore pulp instead of the coarse-grained ore pulp, the dosage of a flotation reagent is reduced, the flotation processes are reduced, and the flotation cost is lower; besides, the operation is simple, the equipment requirement is low, and the popularization and application are facilitated.

Owner:GUIZHOU CHANHEN CHEM CO LTD

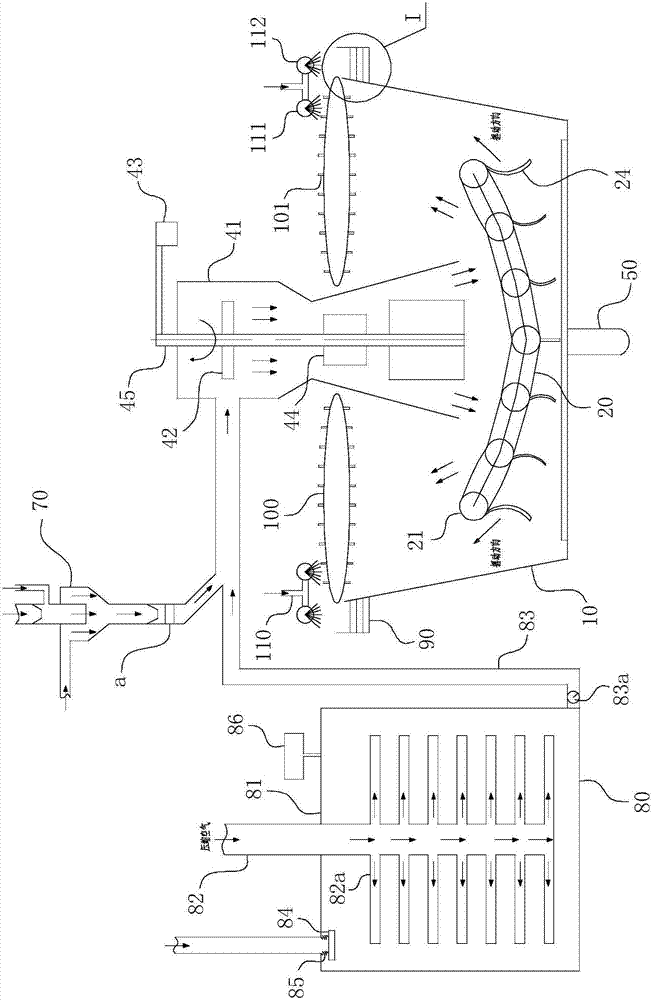

Swinging-stirring flotation equipment with self-slurry-mixing function

ActiveCN105689157AAvoid "sand sinking" situationsTo promote floatingFlotationMicro bubbleEngineering

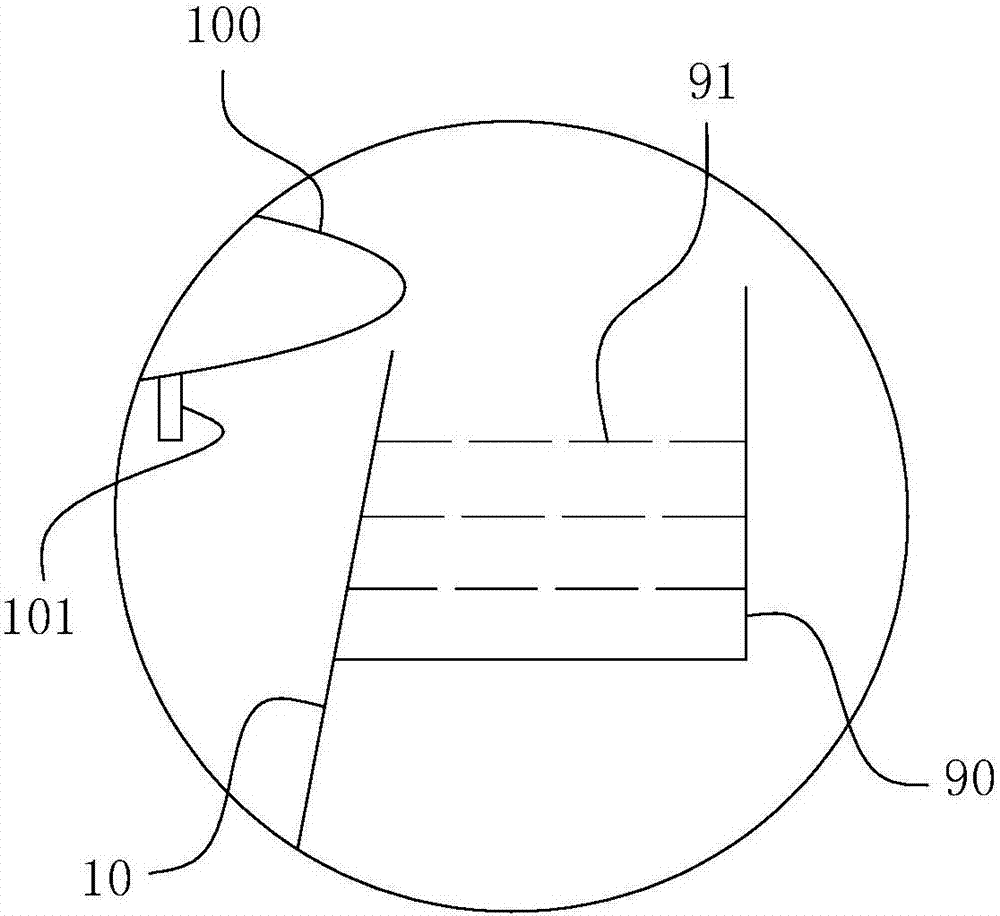

The invention relates to the field of coal slurry mixing and flotation treatment, and specifically relates to swinging-stirring flotation equipment with a self-slurry-mixing function. The swinging-stirring flotation equipment disclosed by the invention at least comprises a flotation cell, wherein a micro-bubble generation bed is arranged in the flotation cell; the micro-bubble generation bed comprises micro-bubble tubes; and a connection arm is arranged at each of the two ends of each micro-bubble tube to fix the co-end part of the micro-bubble tube. The equipment further comprises a gas pipeline, wherein the gas pipeline is communicated with the tube cavity of each micro-bubble tube through a prearranged gas channel in the corresponding connection arm; and micro-bubble generation holes used for ejecting a gas are densely distributed in the tube wall of each micro-bubble tube. The equipment further comprises power arms, wherein the two power arms are provided, and symmetrically arranged at the two sides of the micro-bubble generation bed; and a stirring baffle extends from the bottommost end of each micro-bubble tube, and the surface of each stirring baffle is vertical to the swinging direction of the micro-bubble generation bed. The equipment disclosed by the invention has the advantages of being great in micro-bubble flotation effect, easier in bubble mineralization, free from flotation 'dead areas' in the flotation cell, and more stable in foam layer; and the working efficiency and the flotation effect can both be effectively ensured.

Owner:内蒙古华星煤业有限公司

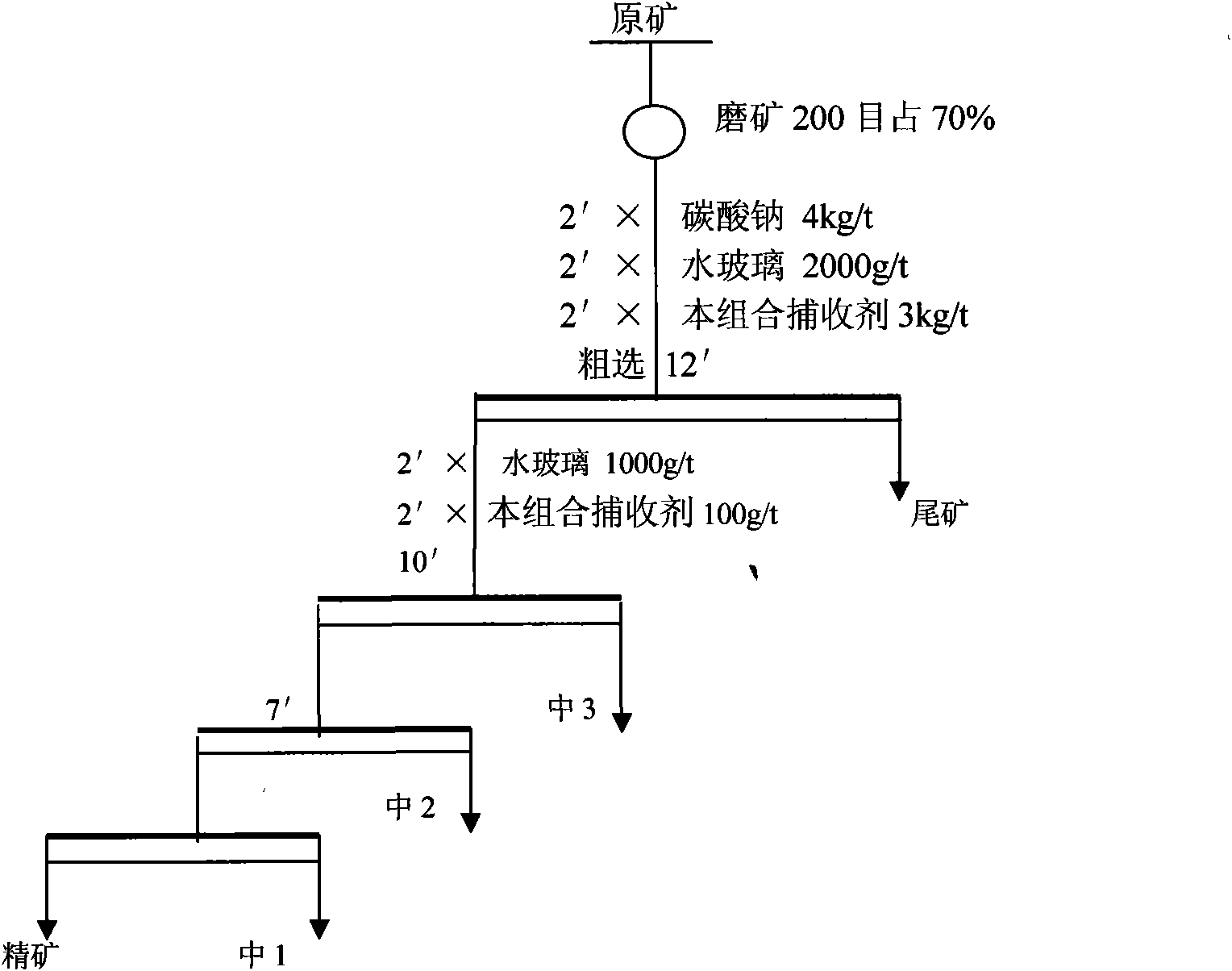

Combined collector of phosphorite

The invention discloses a combined collector of phosphorite. The invention relates to a floatation agent suitable for phosphate mineral with large mud content and belongs to the technical field of mineral machining engineering. The combined collector adopts another two agents which are combined and used in a conventional oxidized paraffin soap collector; the mixture ratio of the combined collector comprises that: the ratio of oxidized paraffin soap to salt to sodium oleate is 2:0.1:1; and three agents synergize to have more obvious and better effect than independently using the oxidized paraffin soap and the sodium oleate. The combined collector is used, can substantially reduce the consumption of sodium carbonate, and is favorable for sedimentation of concentrated ore; and the combined collector has wide source of raw materials, moderate price and market popularization value.

Owner:KUNMING UNIV OF SCI & TECH

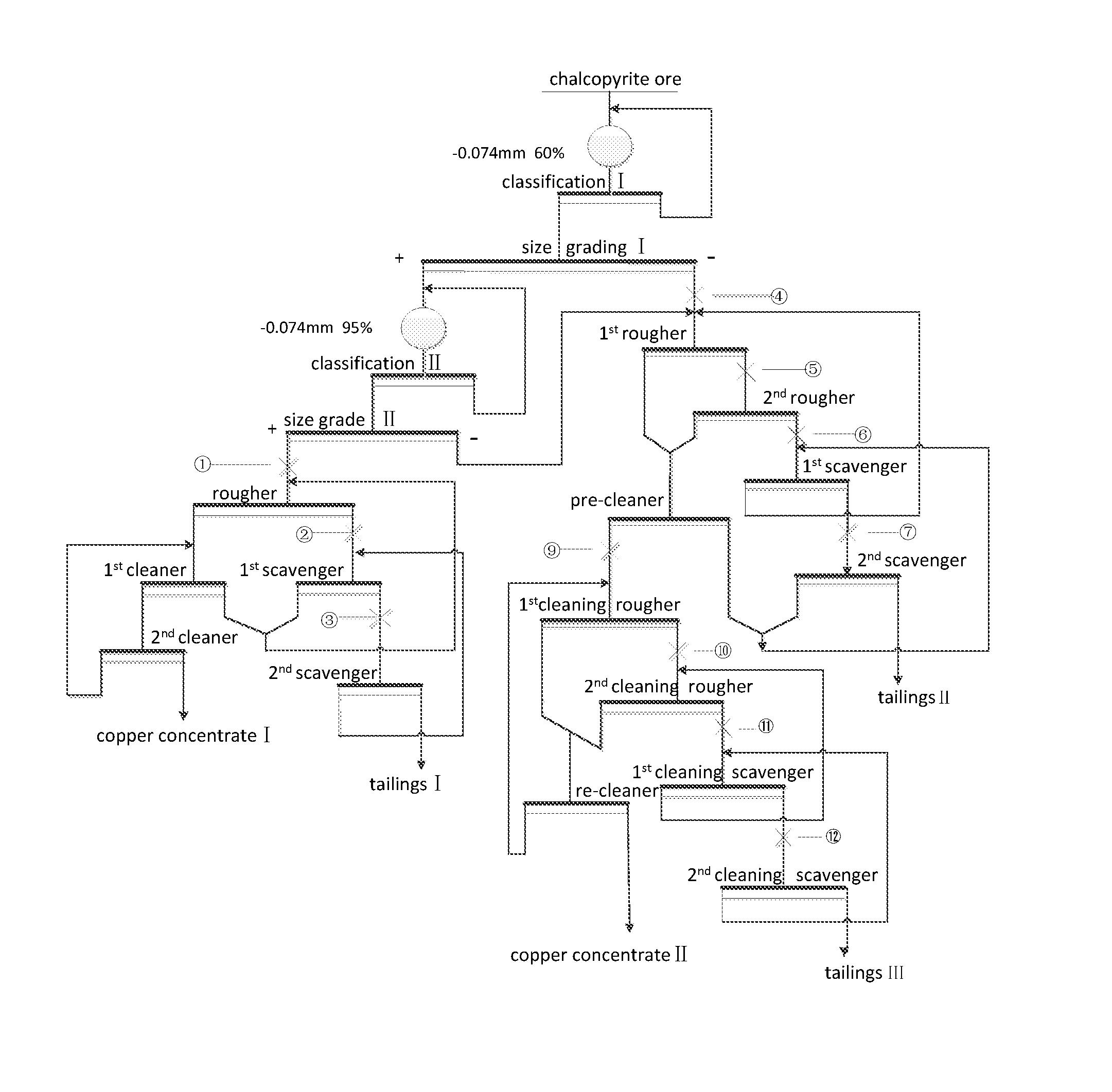

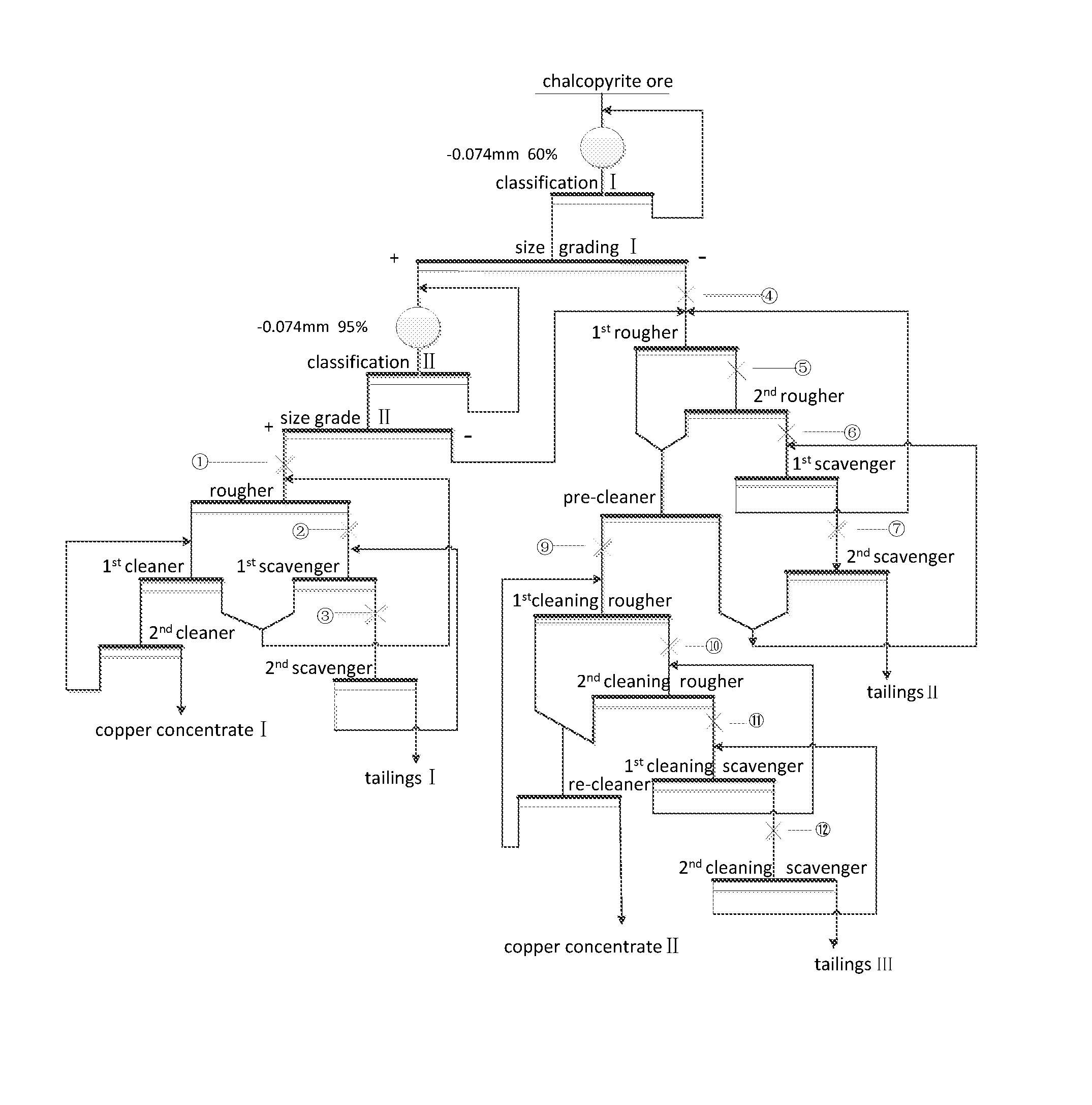

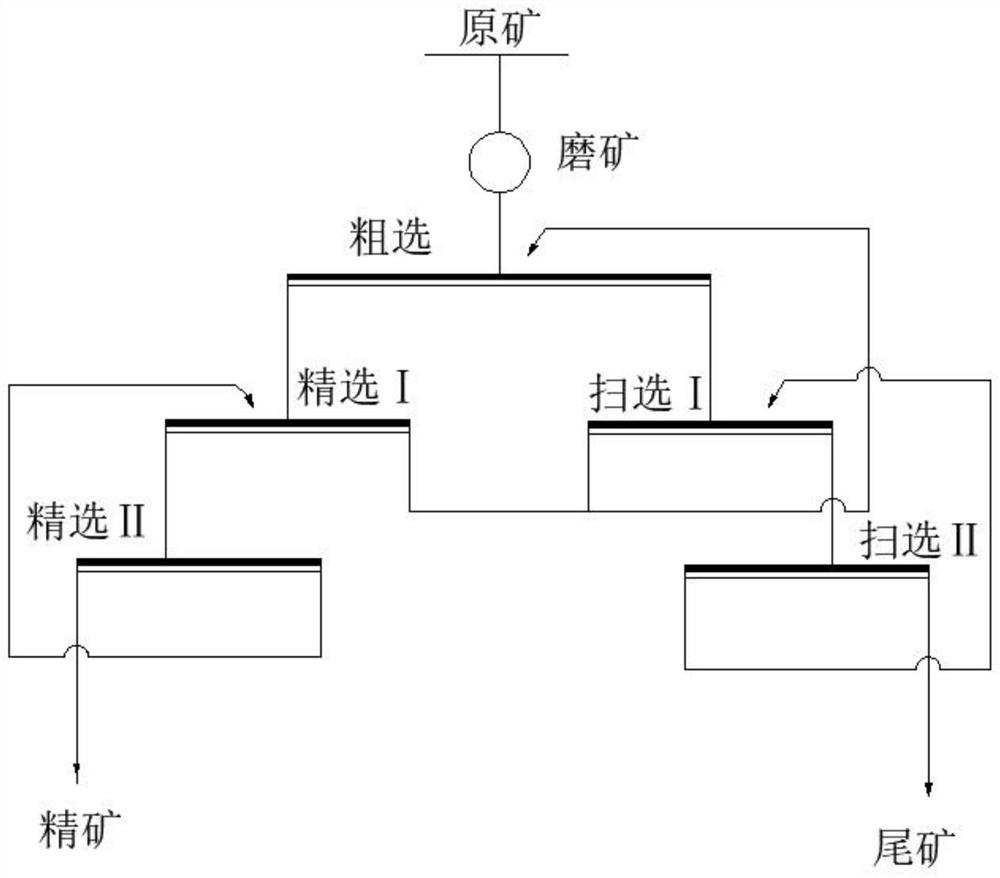

Chalcopyrite ore beneficiation process and method

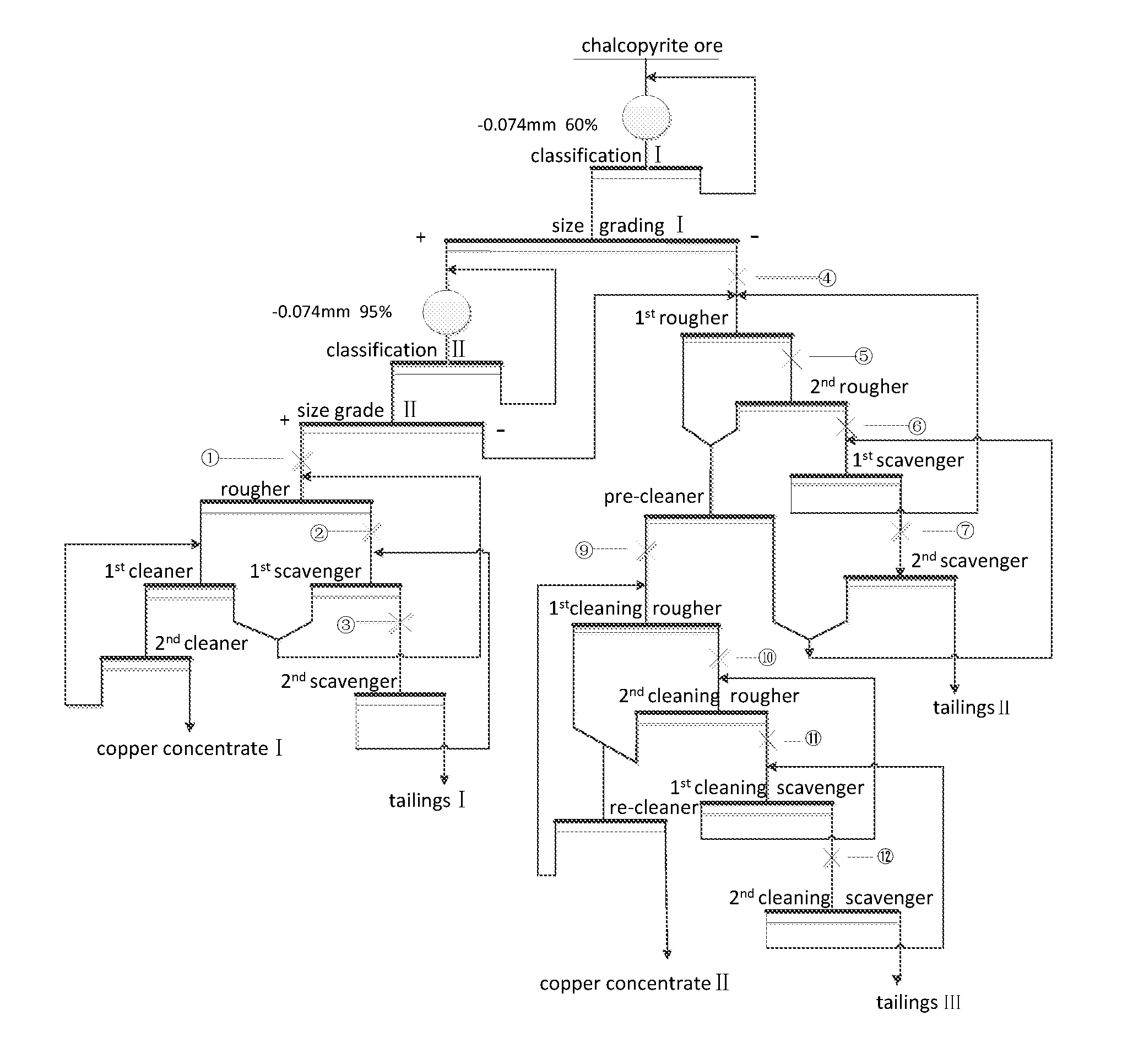

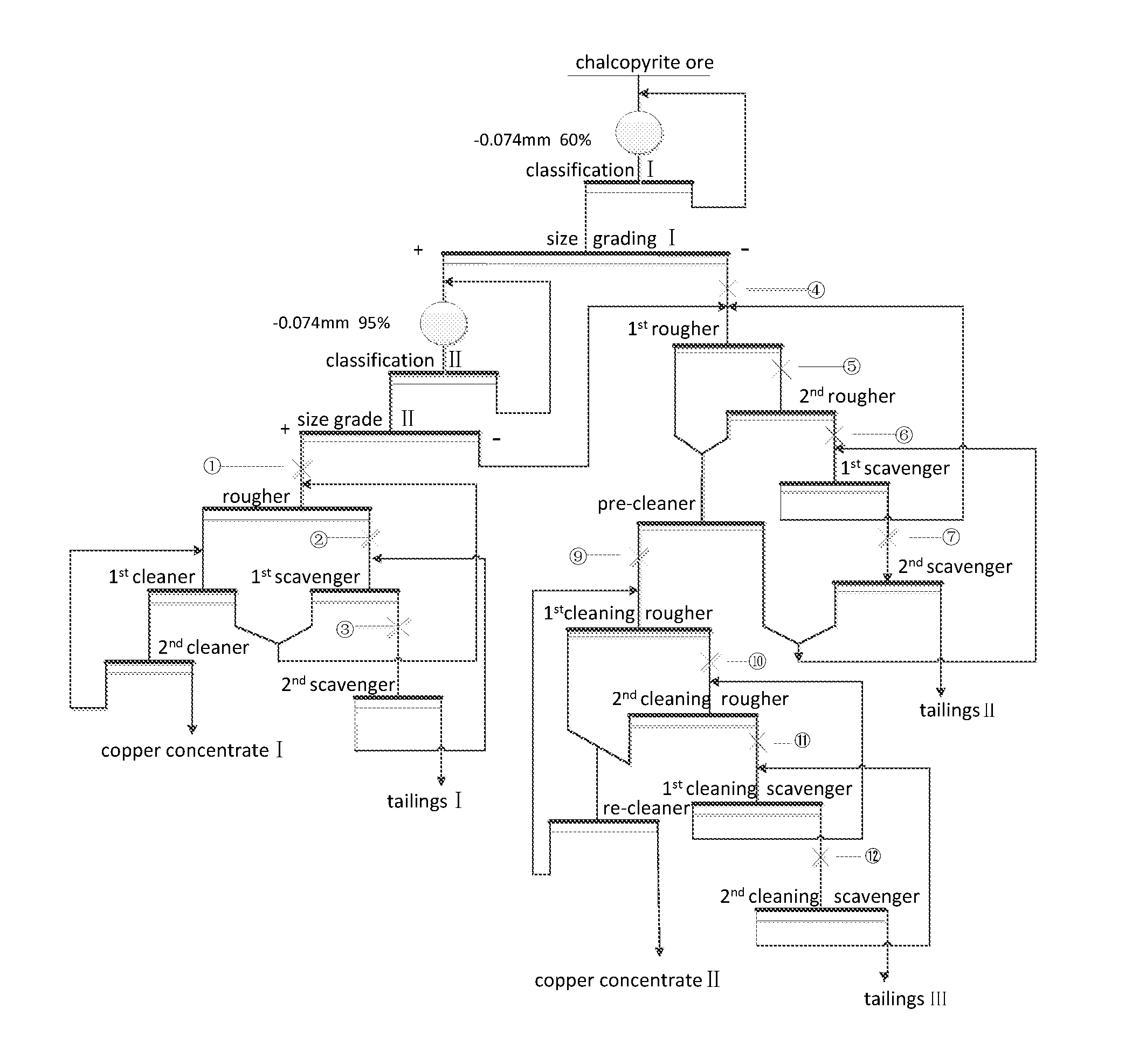

The present invention relates to a mineral processing technology and method for refractory chalcopyrite ores, particularly to a mineral processing technology and method for the separation of chalcopyrite from multiple natural types of copper ores containing chalcopyrite, pyrrhotite, talc and serpentine, which belongs to the technical field of mineral processing. It's characterized by: conducting a two-stage grinding on the chalcopyrite ore, with each grinding stage followed by size grading, and treating ores in different size fractions separately, wherein coarse-grain ores are separated in the presence of xanthate, with calcium oxide and CMC controlling the pH and acting as depressor respectively, while fine-grained ores are subjected to rougher in the presence of kerosene, and subsequently subjected to cleaner in the presence of xanthate.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

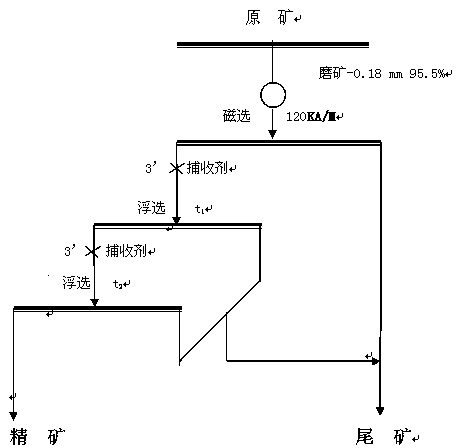

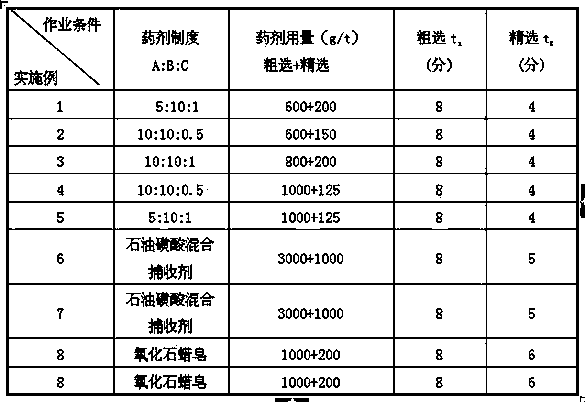

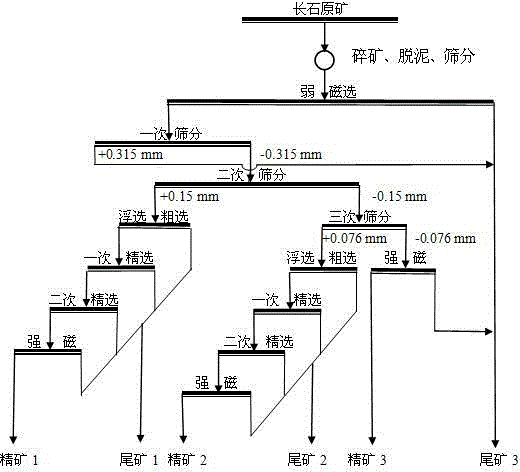

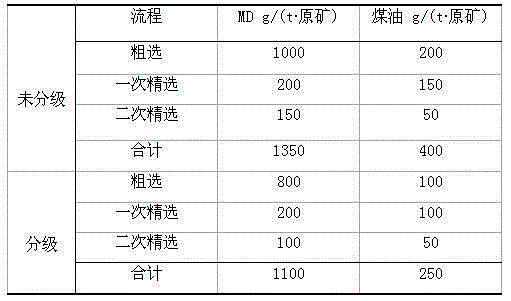

Beneficiation process for quality improvement and iron removal of feldspar ores

ActiveCN103506215ASimple processWide range of ore iron contentFlotationWet separationAlcoholIron removal

The invention discloses a beneficiation process for quality improvement and iron removal of feldspar ores. By adopting the technical scheme, the beneficiation process comprises the steps of first adopting a low-intensity magnetic separation process to perform the iron removal so as to obtain rough feldspar concentrates, wherein the low-intensity magnetic separation intensity is 120-200KA / M; performing reverse flotation on the rough feldspar concentrates at the 46%-52% pulp density to achieve further quality improvement and the iron removal, wherein the reverse flotation step includes one-time rough flotation and fine flotation for one-three times, a reverse flotation collecting agent is sulfonated grease, modified fatty acid, high-carbon mixed alcohol or a mixture of the sulfonated grease, the modified fatty acid and the high-carbon mixed alcohol, the using amount of a rough flotation collecting agent is 600-1000g / t, and the using amount of the fine flotation collecting agent is 1 / 4-1 / 8 of the using amount of the rough flotation collecting agent. The beneficiation process for the quality improvement and the iron removal of the feldspar ores has the advantages that the process is simple, the feldspar concentrate production rate is high, the Fe2O3 content in the concentrates is low, and the operation efficiency is high, and is especially suitable for the iron removal of the feldspar ores which are low in potassium-sodium content and high in iron removal and weathered severely, and a high-quality feldspar concentrate product with lower than 0.15% of Fe2O3 content can be produced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Chalcopyrite ore beneficiation process and method

InactiveUS20160158767A1Reduce the impactEffective selective separationFlotationGrain treatmentsKeroseneTalc

The present invention relates to a mineral processing technology and method for refractory chalcopyrite ores, particularly to a mineral processing technology and method for the separation of chalcopyrite from multiple natural types of copper ores containing chalcopyrite, pyrrhotite, talc and serpentine, which belongs to the technical field of mineral processing. It's characterized by: conducting a two-stage grinding on the chalcopyrite ore, with each grinding stage followed by size grading, and treating ores in different size fractions separately, wherein coarse-grain ores are separated in the presence of xanthate, with calcium oxide and CMC controlling the pH and acting as depressor respectively, while fine-grained ores are subjected to rougher in the presence of kerosene, and subsequently subjected to cleaner in the presence of xanthate.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

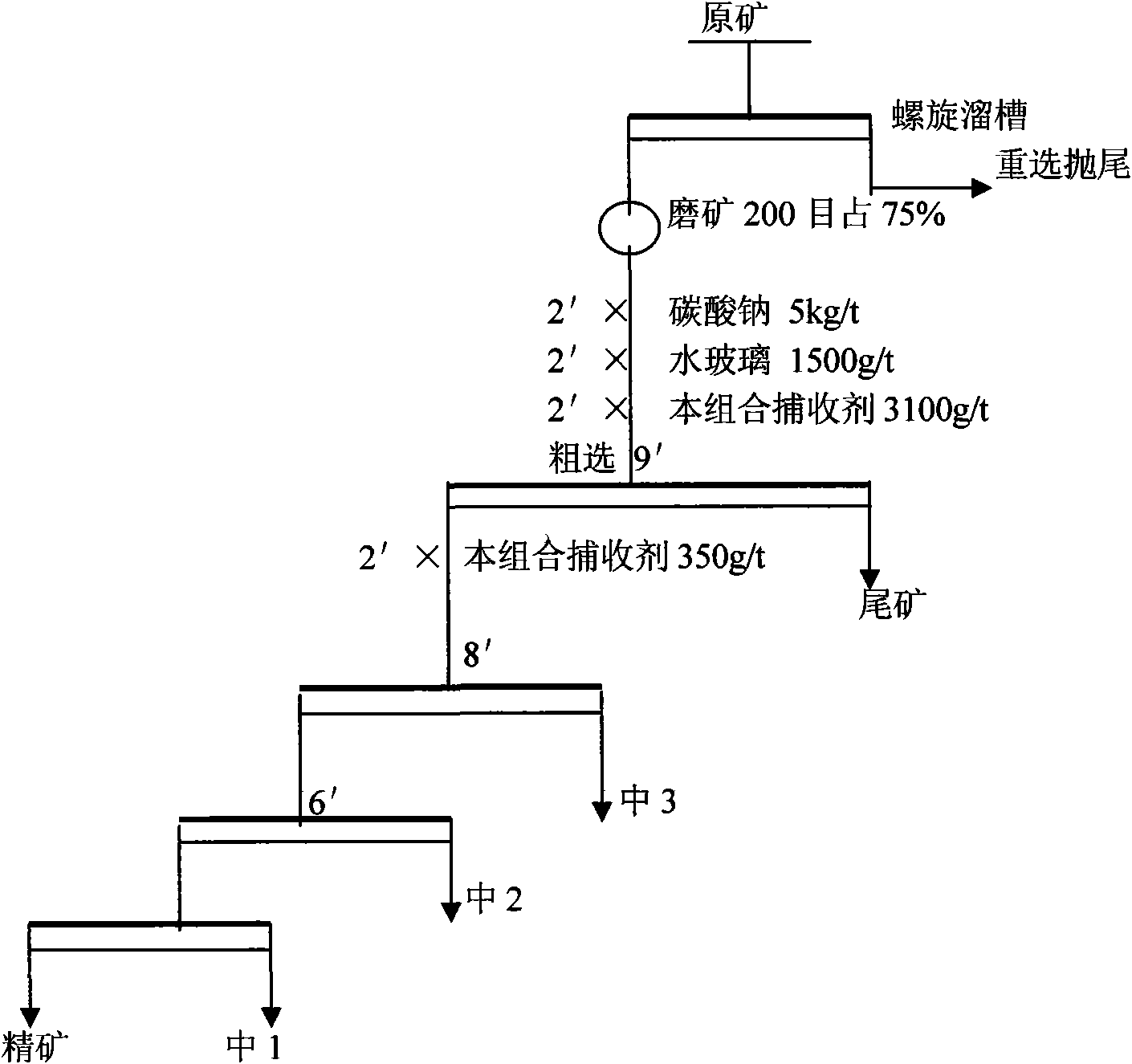

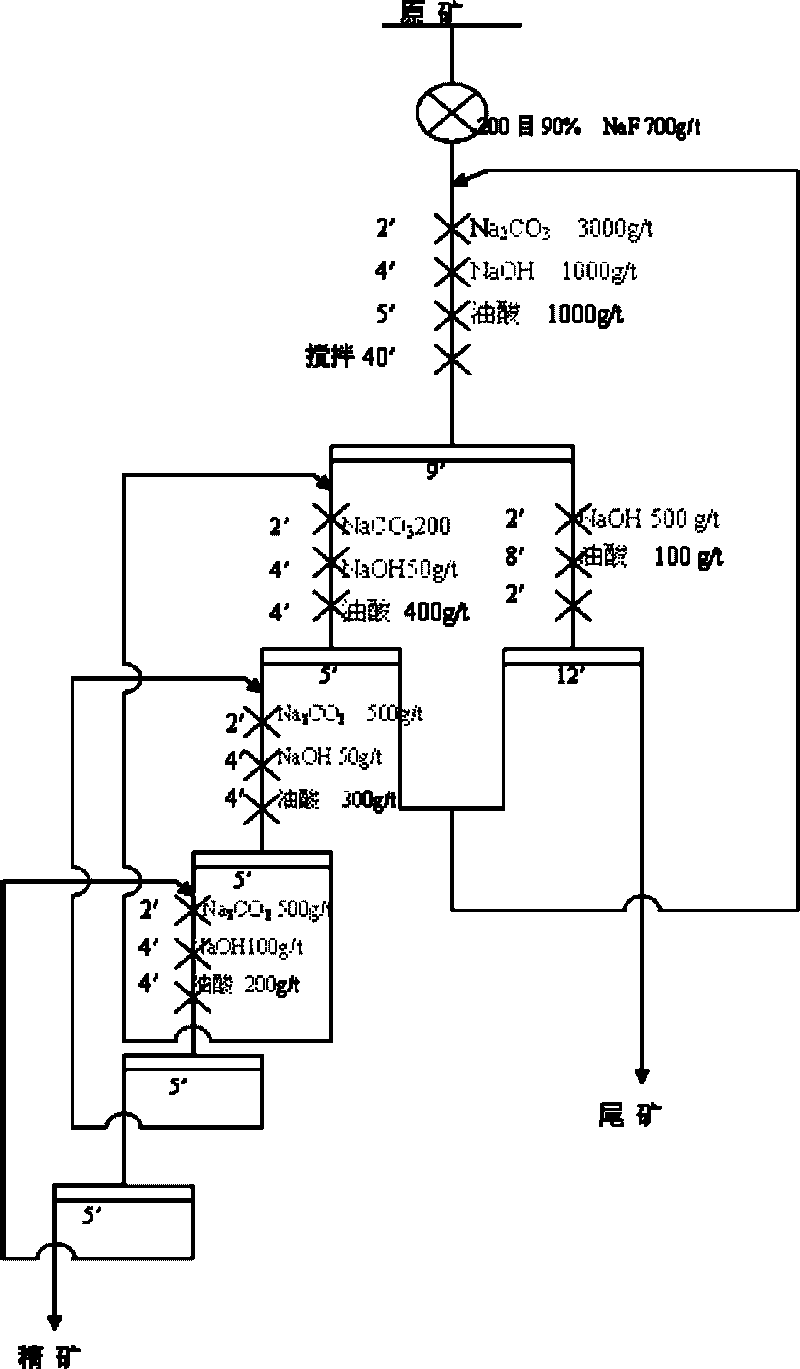

Floatation method for silica-calcium collophane with difficult separation

The invention discloses a floatation method for a silica-calcium collophane with difficult separation. According to the detailed technology, the floatation method includes the steps that (1) breaking and grinding are performed on the silica-calcium collophane; (2), a sulfate mineral negative ion collecting agent, a phosphate mineral negative ion collecting agent and a carbonate mineral negative ion collecting agent are respectively added into ore pulp for mixing and mineralizing, and air inflation is performed for reverse floatation; (3), magnesium removal phosphate ore concentrate is graded; (4), the ore pulp concentration of a coarsely graded phosphate ore concentrate is controlled, then sodium carbonate mineral positive ions and silicate mineral positive ions are respectively added for pulp mixing and mineralizing, and air inflation is performed for reverse floatation; (5), a finely graded phosphate ore concentrate and a desilication phosphate ore concentrate are mixed, and carbonate impurities and silicate impurities are mixed. The problems that because the carbonate impurities are removed only through single reverse floatation, the phosphate ore concentrate is not high in content and high in silicate impurity content, the requirement for the phosphate ore concentrate used for wet-process phosphoric acid can not be met, and then in the process that the silicate impurities are removed through reverse floatation, floatation froth is sticky, not prone to breaking and poor in ore pulp flowability due to the existence of a great deal of slurry are solved, and the floatation method is adaptive to the silica-calcium collophane and efficient in impurity removal.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Low-cost deironing quality-improving beneficiation method for high-impurity-content feldspar quarry

InactiveCN104923384AStrong applicabilityWidely applicableWet separationFroth flotationLower intensity

The invention discloses a low-cost deironing quality-improving beneficiation method for high-impurity-content feldspar quarry. Inferior fine magnetite concentrates of low-intensity magnetic separation operation are divided into four fractions through grading operation of three times, and the concentrates of the coarse fraction of grading operation of the first time are directly thrown out as tailings (3). Rough flotation, fine flotation and the high-intensity magnetic separation process are adopted on the concentrates of the rough fraction of grading operation of the second time. The concentrates of the fine fraction of grading operation of the second time are graded through grading of the third time, and rough flotation, fine flotation and the high-intensity magnetic separation process are adopted on the concentrates of the rough fraction of grading operation of the third time. High-intensity magnetic separation operation is directly carried out on the concentrates of the fine fraction of grading operation of the third time to obtain concentrates (3). The grading treatment process is adopted, and products of different qualities and purposes can be obtained according to different purposes. The particle size of products of all fractions after grading is concentrated, few flotation reagents are adopted, and the flotation cost is low. The productivity and ferric oxide recycling rate of grading flotation are high, and all flotation indexes are good. The deironing beneficiation process for feldspar is good in applicability, and can be used for grading various types of feldspar quarry.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

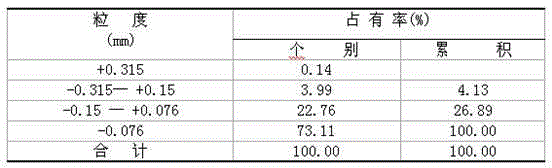

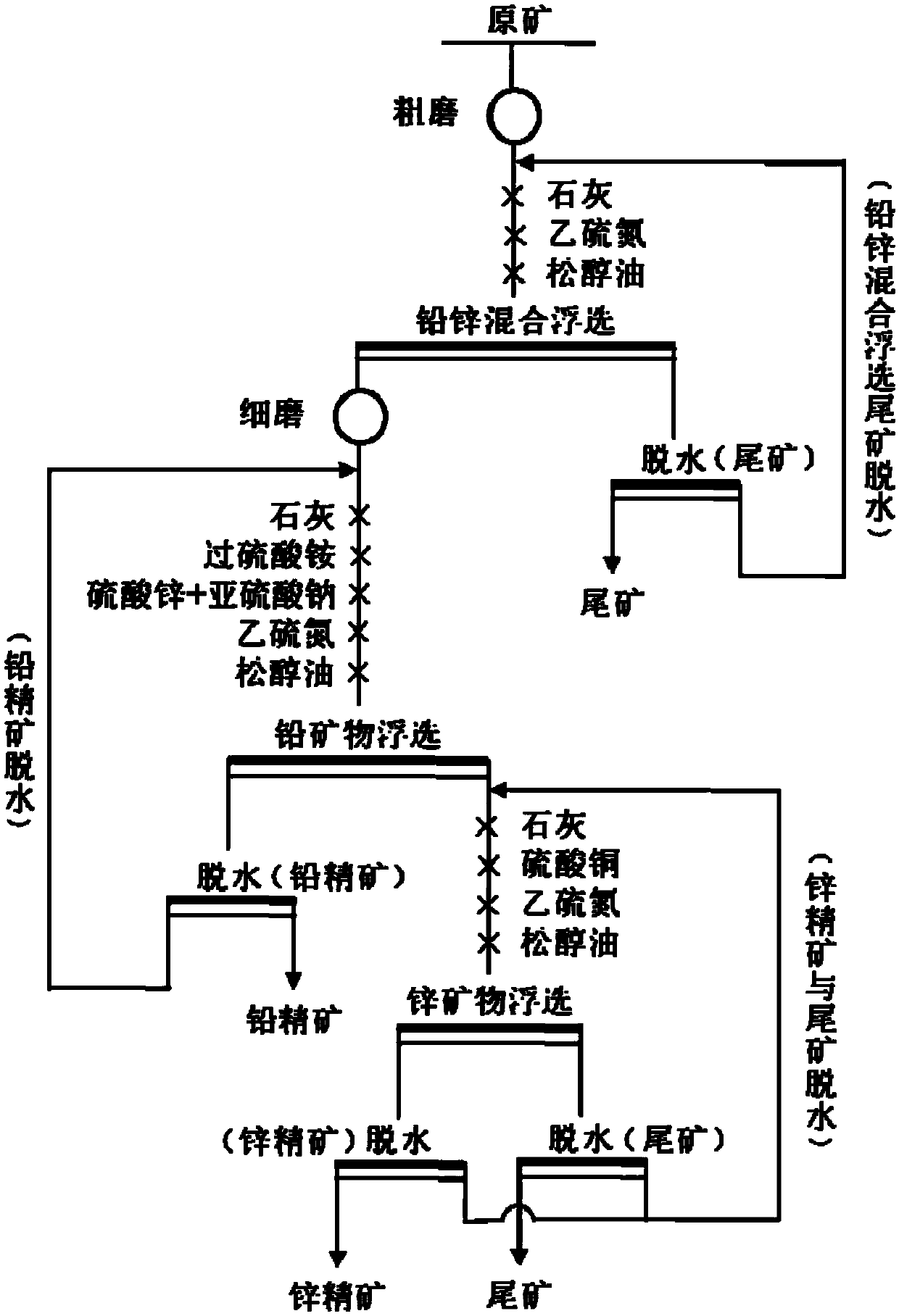

Floatation separation technology of refractory lead-zinc sulphide ores

ActiveCN107812616AImprove flotation efficiencyReduce flotation costsFlotationFoaming agentSeparation technology

The invention provides a floatation separation technology of refractory lead-zinc sulphide ores. The floatation separation technology comprises the steps that rough grinding is conducted on the lead-zinc sulphide ores, a pH regulator, a collector and a foaming agent are added, so that lead-zinc bulk floatation is conducted and lead-zinc bulk concentrates are obtained; and fine grinding is conducted on the lead-zinc bulk concentrates, a pH regulator, an electric potential regulator, an inhibitor and the like are added, so that lead ore floatation is conducted and lead concentrates are obtained,in the process, an electric potential of ore pulp is adjusted to be 210-350 mv by the electric potential regulator, and a pH value of the ore pulp is adjusted to be 9-11 by the pH regulator. A pH regulator, an activating agent and the like are added into lead ore floatation tailings, zinc ore floatation is conducted, and zinc concentrates and zinc ore floatation tailings are obtained. The lead-zinc floatation separation difficulty is reduced by adding the electric potential regulator, meanwhile waste water produced at various floatation stages is separated and independently recovered, the floatation separation technology is suitable for floatation separation of the lead concentrates and the zinc concentrates with high grades and recovery rates at low production cost from the refractory lead-zinc ores which are low in lead content and high in zinc content, and the application prospect is good.

Owner:SANMING UNIV

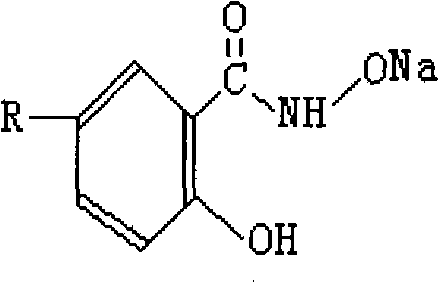

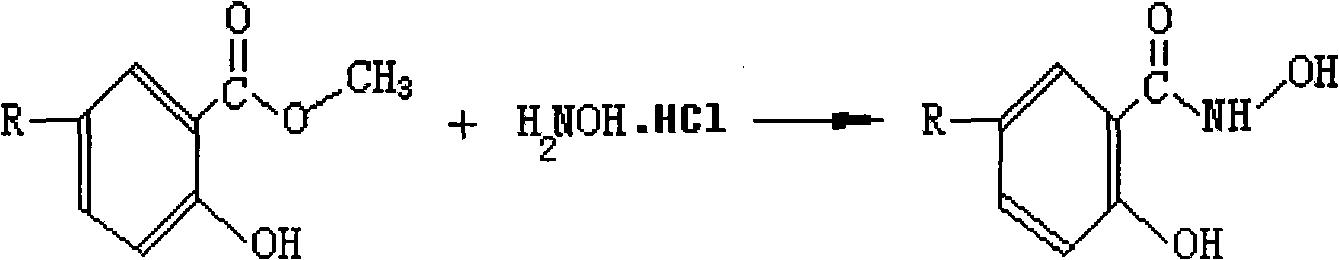

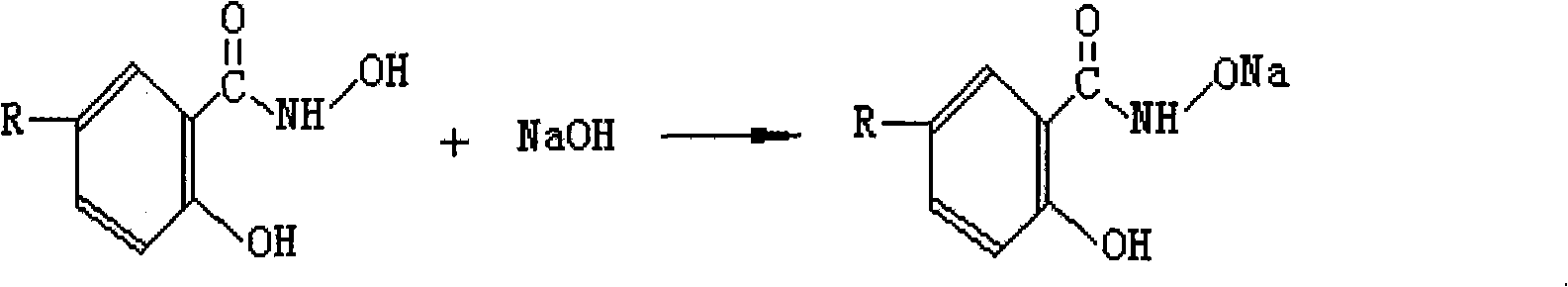

Hematite low temperature flotation agent and preparation method thereof

InactiveCN101618369AChemically stableStable in natureFlotationCarboxylic acid salt preparationBenzoic acidChemical composition

The invention relates to a hematite low temperature flotation agent and a preparation method thereof; the agent is the water solution of 2-hydroxyl-5-alkyl-sodium benzoic acid ammonium salt and sodium aliphatate in a ratio of 1:1-3 and the concentration of each solute is not less than 0.02mol / L. The preparation method comprises the following steps: preparing sodium aliphatate solution, preparing hematite collector 2-hydroxyl-5-alkyl-sodium benzoic acid ammonium salt solution, and then mixing the two solutions. The agent can be used for hematite roughing, the dosage is 0.01-0.18% of hematite and the flotation temperature is 20-30 DEG C. the preparation method of the invention has simple method, non-toxic and sate raw materials and stable chemical compositions and properties of the preparedflotation agent.

Owner:NORTHEASTERN UNIV

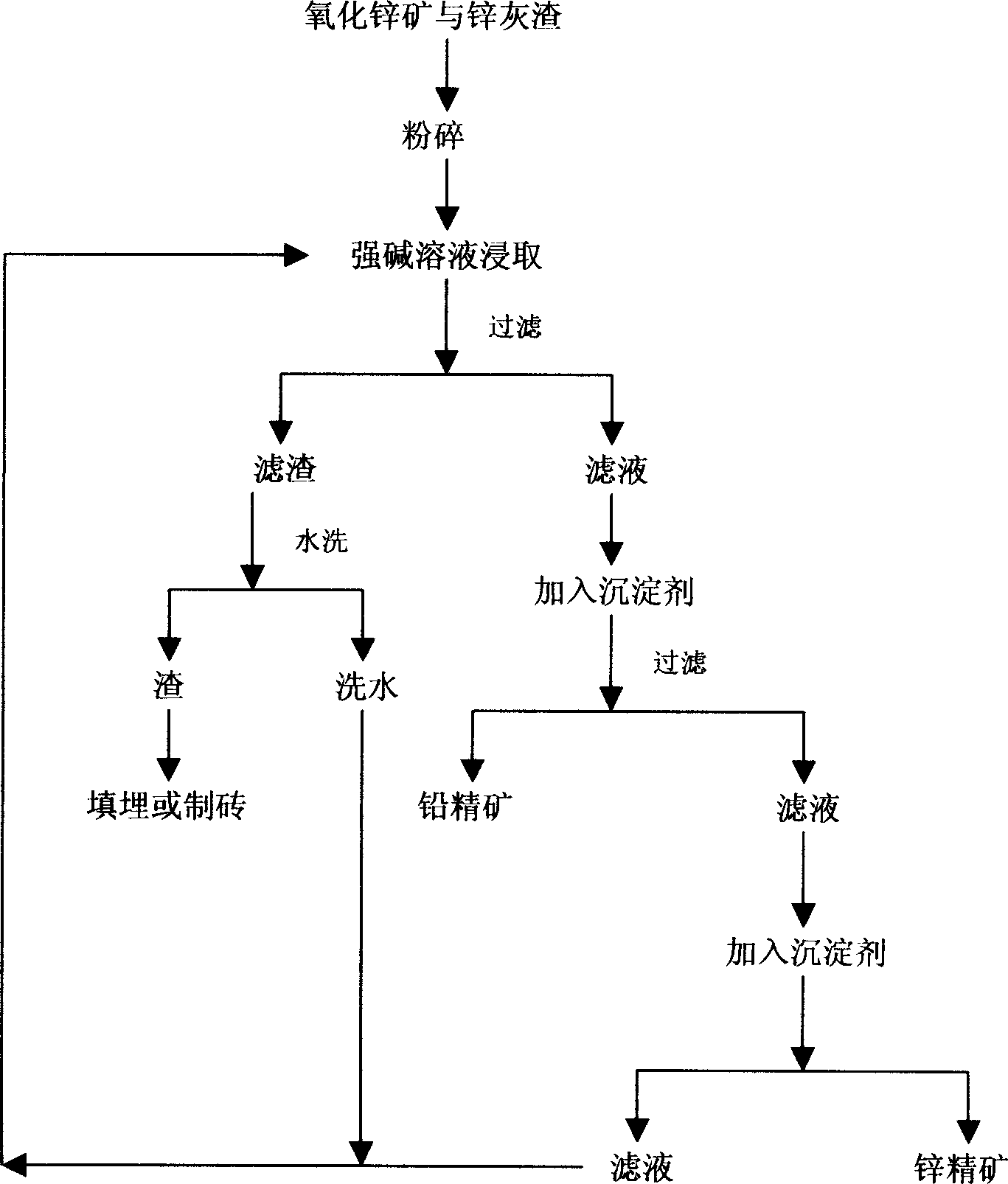

Mehtod for producing zinc concentrate and lead concentrate using zinc oxide ore and zinc slag

InactiveCN1858275AGood environmental and social benefitsSimple processProcess efficiency improvementSlagLow graded

The process of producing zinc concentrate and lead concentrate with zinc oxide and zinc slag includes the following steps: grinding material to granularity of 0.1-1mm, leaching in strong alkaline solution, stirring at 10-100deg.c for 60-100 min to leach out zinc and lead from the material; filtering, water washing filter residue, and producing slag brick or land filling of filter residue; adding precipitant in 0.5-3 times the lead content, stirring for 60 min, and filtering to obtain lead concentrate; adding precipitant in the amount of 0.5-5 times zinc content, stirring at 10-100 for 1-5 hr and filtering to obtain zinc concentrate; and returning filtrate and washing water for reuse. The present invention has simple technological process, low production cost and no environmental pollution, and can utilize zinc and lead resource, especially low grade resource, effectively.

Owner:TONGJI UNIV

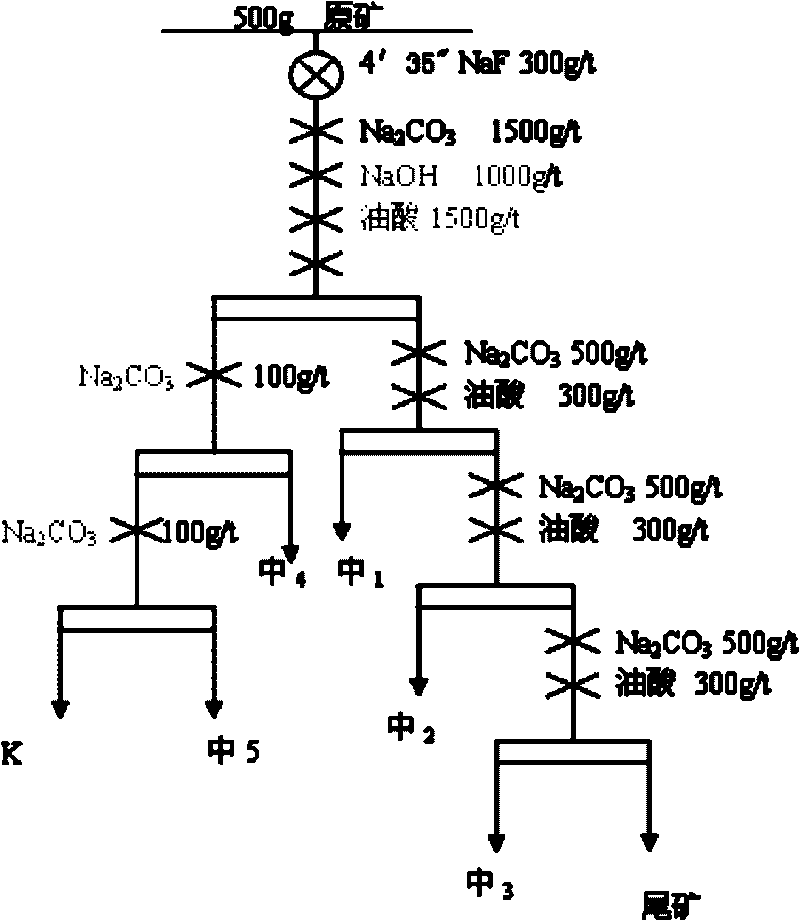

Efficient ore dressing method for bertrandite

InactiveCN101722109AEfficient separationTo achieve the purpose of enriching beryllium oreFlotationBeryllium oxideBeryllium Metal

The invention discloses an ore dressing method for bertrandite. The invention adopts the technical scheme that the method adopts a comminuting-flotation process, uses an inhibitor to inhibit gangue, uses an efficient activator to activate the beryllium ore and uses a collecting agent to float and reclaim beryllium. By treating the phenacite containing 0.17 percent of beryllium through the technology, the phenacite containing 3.21 percent of beryllium metal, namely 8.92 percent of beryllium oxide, can be obtained; the reclaiming rate reaches 85.18 percent; and the method can meet the requirement of good-quality raw materials smelted by beryllium ores, provides a new efficient path for comprehensive utilization of beryllium ore resources in China, and has the advantages of simple process flow, good effect, no pollution and the like compared with the current process for extracting the beryllium by a sulfuric acid method.

Owner:CENT SOUTH UNIV

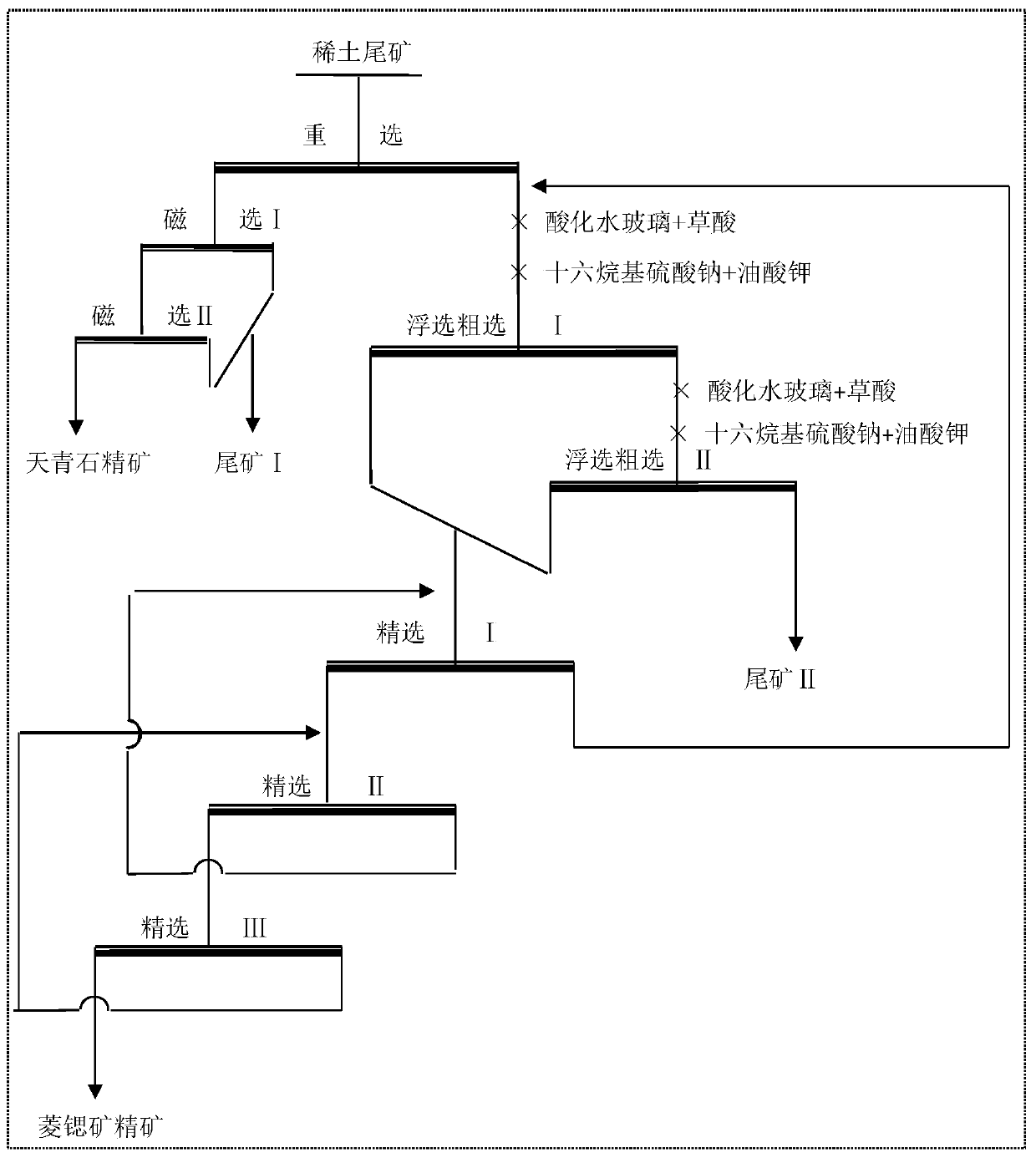

Beneficiation method for comprehensively recycling strontium mineral from rare earth tailings

The invention discloses a beneficiation method for comprehensively recycling a strontium mineral from rare earth tailings and relates to a beneficiation method for the rare earth tailings containing celestite and strontianite. The beneficiation method comprises the following steps that (1) heavy minerals in the rare earth tailings are screened out through gravity concentration, so that gravity concentrate is obtained; (2) rare earth, iron and other magnetic minerals in the gravity concentrate in the step (1) are attracted out through strong magnetic separation, so that celestite concentrate isobtained; (3) the strontianite mineral in the gravity tailings in the step (1) is floated out through flotation, so that strontianite concentrate is obtained. The beneficiation method for comprehensively recycling the strontium mineral from the rare earth tailings has the beneficial effects of remarkably recycling the strontium mineral from the rare earth beneficiation tailings, improving the comprehensive utilization value of resources and greatly lowering the discharge amount of tailings.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

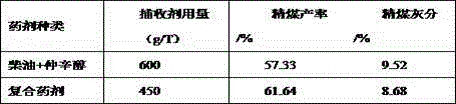

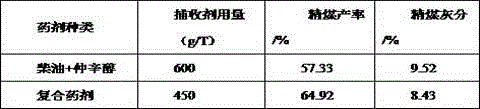

Coal dressing composite reagent and preparing method thereof

The invention discloses a coal dressing composite reagent and a preparing method thereof. Raw materials used in the preparing method of the coal dressing composite reagent include, by mass percent, 65% of arene residual liquid, 15% of butanol and octanol residual liquid, 5% of light diesel oil, 1%-5% of an emulsifying agent and 10%-14% of water. The manufacturing method of the coal dressing composite reagent comprises the following steps that the arene residual liquid, the butanol and octanol residual liquid and the light diesel oil are mixed according to a required proportion and put into a reaction kettle with a stirring function, stirring is conducted for 30 min, and mixed oil liquid is formed; and the emulsifying agent and the water are mixed according to a required proportion, a mixed solution of the emulsifying agent and the water is obtained, the mixed solution of the emulsifying agent and the water is added to the obtained mixed oil liquid under the stirring condition at the stirring rate of 100 rmp, and stirring is conducted continuously till the solution is brown. Selectivity of hydrocarbon oil on cleaned coal can be improved through the coal dressing composite reagent, a floatation effect is improved, the floatation cost is saved, in addition, products high in additional value are produced by reasonably utilizing the arene residual liquid, and very good economic benefits and social benefits are achieved; and meanwhile the beneficial effects of facilitating energy saving and emission reducing, improving the economic benefits and the like are achieved.

Owner:江苏禹山机械科技有限公司

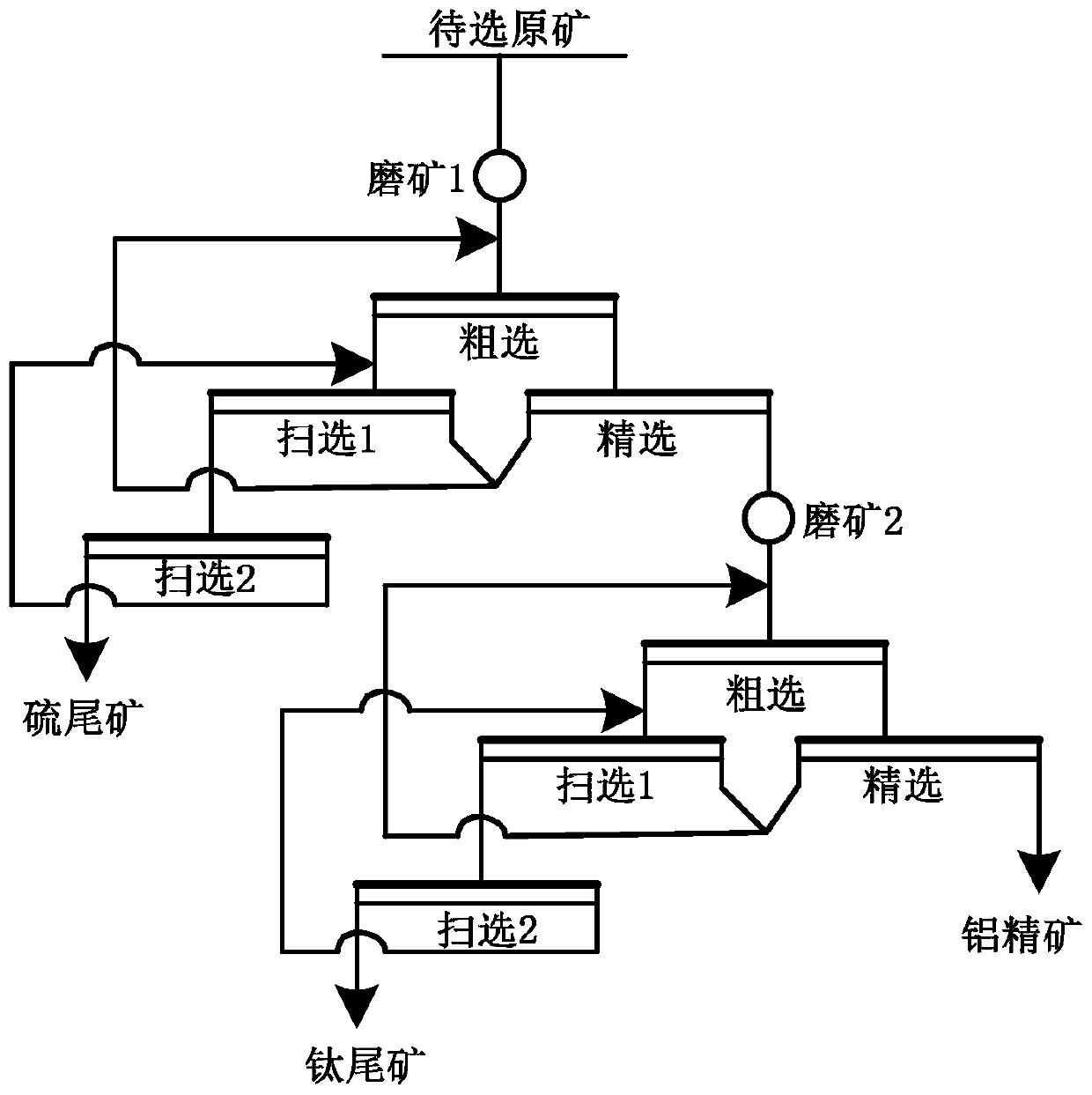

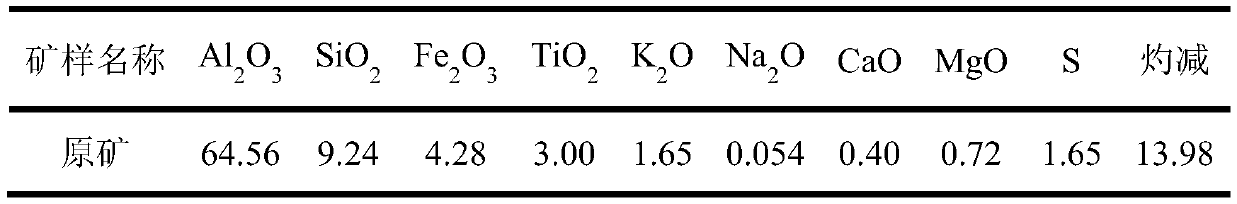

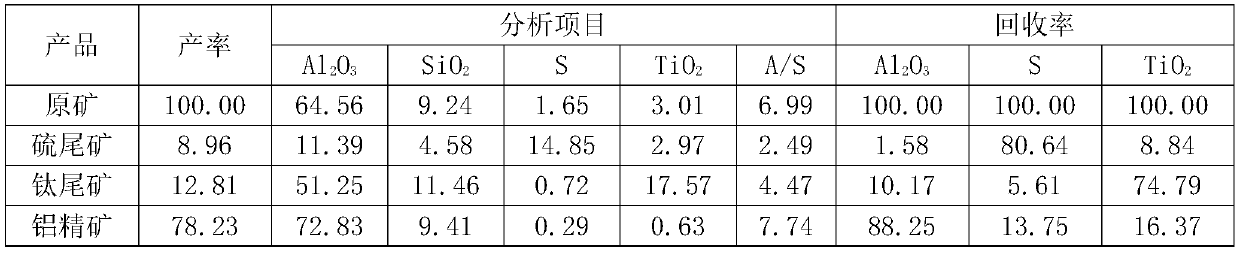

Method for removing titanium minerals in high-sulfur bauxite

The invention provides a method for removing titanium minerals in high-sulfur bauxite, and the method comprises the following steps: crushing and grinding high-sulfur bauxite raw ore to obtain ore pulp, and adding an activating agent, a desulfurization collecting agent and a foaming agent to perform sulfur mineral flotation to allow sulfur minerals to float upwards to obtain desulfurized aluminumconcentrate; and grinding the aluminum concentrate again, adding an adjusting agent and a composite titanium removal collecting agent for titanium mineral flotation to allow the titanium minerals to float upwards and separate to can be removed. According to the method for removing the titanium minerals in the high-sulfur bauxite, an asynchronous reverse flotation method is adopted for treating thehigh-sulfur bauxite, the sulfur minerals and the titanium minerals are removed respectively, the content of the titanium minerals in the bauxite is reduced, harm of the titanium minerals in the subsequent Bayer process dissolution process is reduced, and efficient utilization of high-sulfur bauxite resources can be achieved.

Owner:GUANGZHOU CITY CONSTR COLLEGE

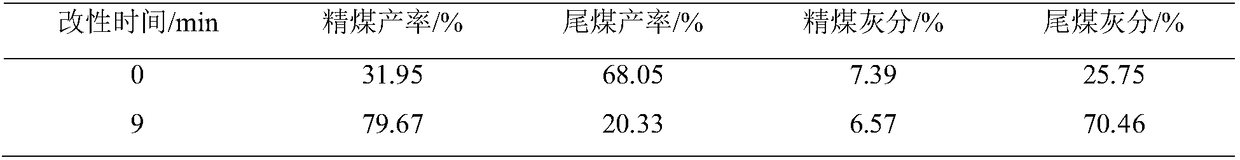

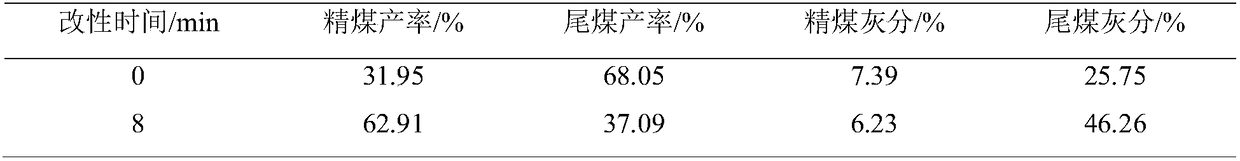

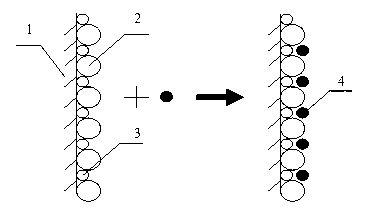

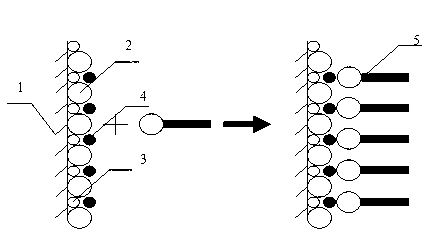

Method for preparing low-rank coal slime bipolar collecting agent through modification of hydrocarbon-type oil

ActiveCN108325755AHigh activityEnhanced harvesting capacityFlotationLow temperature plasmaPlasma reactor

The invention discloses a method for preparing a low-rank coal slime bipolar collecting agent through modification of hydrocarbon-type oil. The bipolar collecting agent is formed through reaction of the hydrocarbon-type oil and air. The preparing process comprises the following steps that 1, the conventional hydrocarbon-type oil is fed into a low-temperature plasma reaction chamber; 2, a reactionchamber body is placed in an oscillator for 3-5 min, and medicament is evenly distributed in the reaction chamber; 3, air with the quantity of flow being 30 L / (min.m<2>) is led into a plasma reactor;4, the low-temperature plasma reactor is started to make the hydrocarbon-type oil react with the air for 5-10 min; 5, the low-temperature plasma reactor is shut down; and 6, air leading is stopped, reaction products are taken out of the reactor, and the bipolar collecting agent is prepared. The method for preparing the low-rank coal slime bipolar collecting agent through modification of the hydrocarbon-type oil has the advantages that the preparation method is simple, raw materials are easy to get, the process is efficient, and the medicament property is stable by taking chemical change as priority; and by using the collecting agent prepared through the method, the low-rank coal slime flotation clean coal productivity can be greatly improved under the same medicament dosage.

Owner:CHINA UNIV OF MINING & TECH

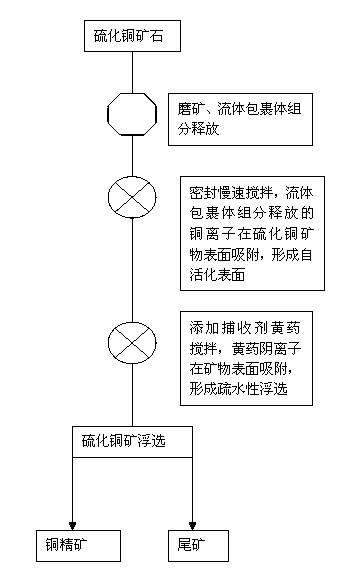

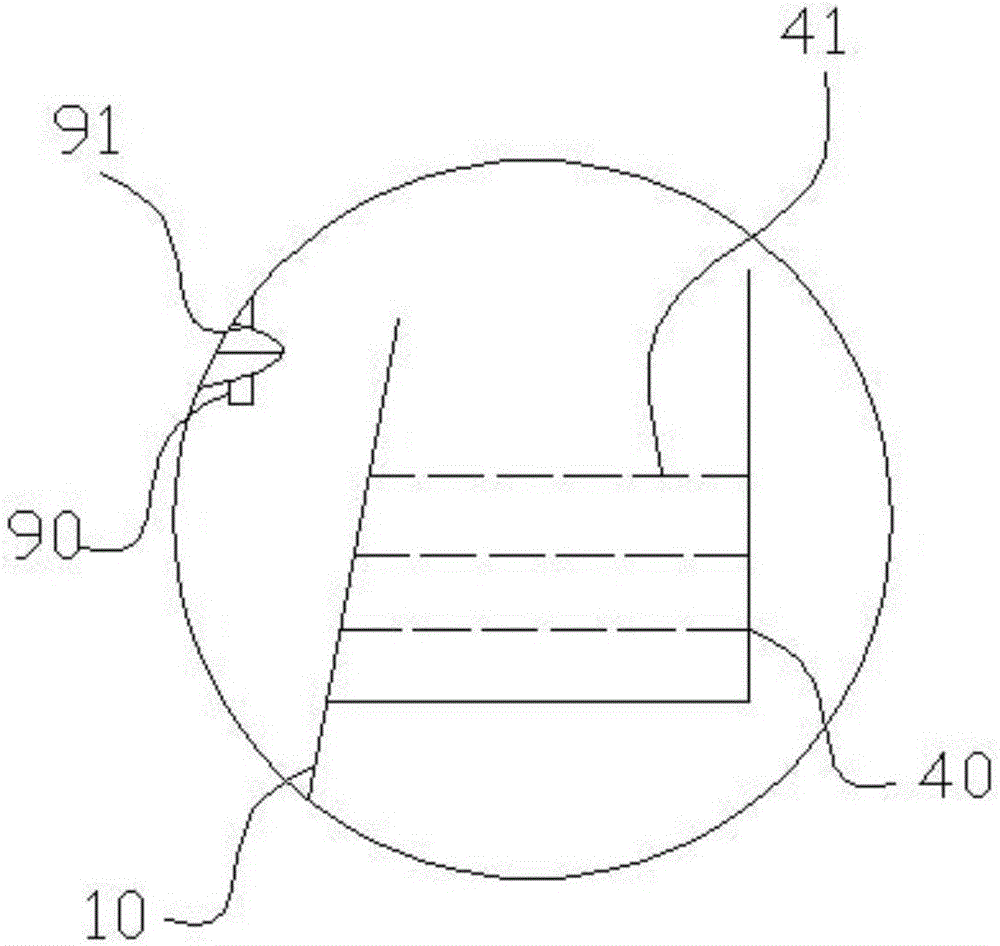

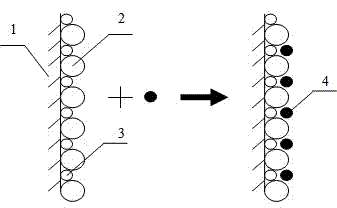

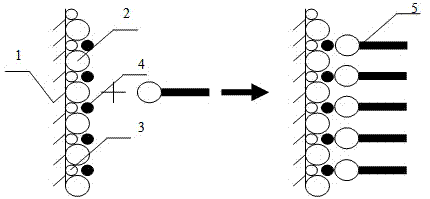

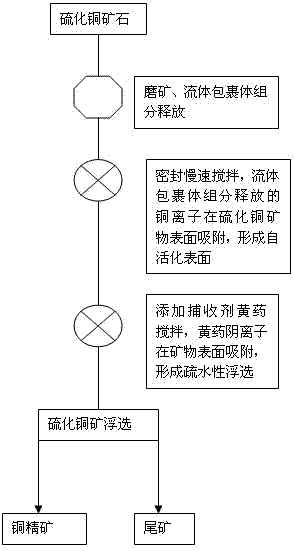

Self-activation flotation method for component of fluid inclusion of copper sulfide ore

The invention relates to a self-activation flotation method for a component of a fluid inclusion of a copper sulfide ore. Specific to the 'rich sulfur' state formed by surface relaxation of the copper sulfide ore, by utilizing the characteristics that copper ions released by the fluid inclusion of the copper sulfide ore have ultrahigh adsorption activity on a 'rich sulfur' surface, the copper ions of the component of the fluid inclusion are attached to a new surface of the copper sulfide ore so as to form a 'rich copper' surface, so that the adsorption activity of the surface of the copper sulfide ore to xanthate anions is increased, the self-activation flotation for the surface of the copper sulfide ore is realized, the flotation recovery of the copper sulfide ore is increased, the dosage of collecting agents is reduced and the technical and economic targets are increased.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

Flotation reagent for gold-containing thiocyanic castaway slag

The invention discloses a flotation reagent for gold-containing thiocyanic castaway slag. The flotation reagent is composed of, by weight, 200-320 parts of sodium hexametaphosphate, 1500-2500 parts of sodium silicate, 40-60 parts of ethionine ester, 30-55 parts of copper sulfate, 66-110 parts of butyl xanthate, 133-220 parts of sodium isoamylxanthate and 50-110 parts of oil No.2. The sodium hexametaphosphate is adopted for inhibiting gangue; the sodium silicate is adopted for inhibiting iron minerals; the ethionine ester Z-200 serves as a collecting agent of copper sulphide; the copper sulfate serves as an activating agent; the butyl xanthate and the sodium isoamylxanthate serve as collecting agents; the oil No.2 serves as a foaming agent. When the flotation reagent is adopted for flotation of enriched concentrate fines, the grade is greatly increased; the metal content of flotation slag is low; the recovery rate is up to 80%; the gold-containing grade of enriched concentrate is increased to 20g / t, the silver grade is increased to 220g / t, and the sulphur content is up to 33%. The flotation cost is reduced to a great extent, resources are effectively recovered, and the environment is protected.

Owner:河南黄金产业技术研究院有限公司

Melamine derivative compound calcium magnesium inhibitor for phosphate ore flotation and preparation and application method of melamine derivative compound calcium magnesium inhibitor for phosphate ore floatation

The invention discloses a melamine derivative compound calcium magnesium inhibitor for phosphate ore floatation and a preparation and application method of the melamine derivative compound calcium magnesium inhibitor for phosphate ore floatation. The preparation method comprises the steps that firstly melamine, formaldehyde and sodium pyrosulfite are adopted and generate a reaction under the alkaline condition, and melamine hexasulfonic is prepared; then melamine hexaacetic acid is prepared; and finally the melamine hexasulfonic, the melamine hexaacetic acid and a synergist OP-10 are jointly added to a reactor, in the presence of the strong alkaline, basic materials are prepared, water is added for diluting, and the inhibitor is obtained. The synthetic process and the compound process of the inhibitor are simple and easy to implement, the reaction condition is mild, and the two kinds of melamine derivatives and the synergist are compounded; and complexing of calcium and magnesium minerals can be achieved more effectively under the synergetic action of the two kinds of melamine derivatives, the removal rate of oxide magnesium in the direct flotation process is increased, the direct-reverse flotation process is simplified as a one-step direct flotation process, the amount of a collector is reduced, the cost of flotation is lowered, and the melamine derivative compound calcium magnesium inhibitor and the preparation and application method are of great significance.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

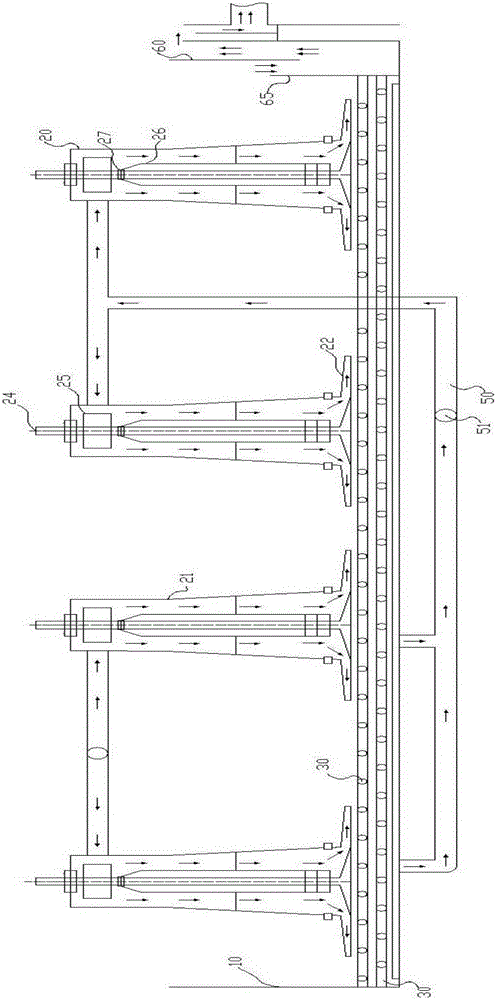

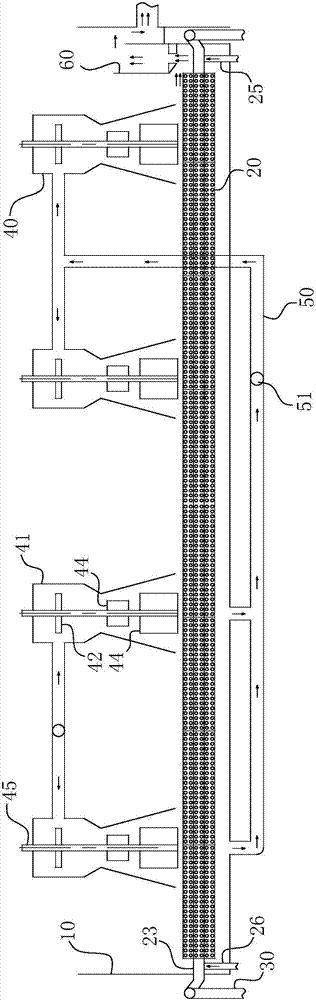

Rotary jet mixing low-energy consumption flotation equipment driven by utilizing ore pulp

The invention relates to the field of coal slime flotation treatment, in particular to rotary jet mixing low-energy consumption flotation equipment driven by utilizing ore pulp. The rotary jet mixing low-energy consumption flotation equipment at least comprises a flotation groove, wherein jet driving mixers are arranged in the flotation groove; each jet driving mixer comprises a driving turbine and a swirl jet mixing rotor which are separately connected to the upper part and the lower part of a rotary shaft, and the rotary shaft rotates under the joint action of driving force of the corresponding driving turbine and nozzle jet reactive force; the residue power of conveyed ore pulp is fully utilized, so that flotation mixing in the groove is realized; the rotary jet mixing low-energy consumption flotation equipment further comprises micro foam generation beds which are formed by micro foam generation pipes and are divided into an upper layer and a lower layer; the micro foam generation beds are arranged in a staggered manner and are not coincided with each other; micro foam generation holes are uniformly distributed in each micro foam generation pipe; and the left end and the right end of the micro foam generation beds are separately provided with a gas pipeline and a cleaning water pipeline. The rotary jet mixing low-energy consumption flotation equipment has the advantages that mixing energy consumption is low; the micro foam flotation effect is good; no flotation dead zones exist in the flotation groove; a foam layer is more stable; the work efficiency and the flotation effect both can be effectively ensured.

Owner:滦平县小营乡利民矿业有限公司

Catching agent for reverse flotation of carbonate and silicate in phosphorite at same time and preparation method for same

The invention relates to a catching agent for reverse flotation of carbonate and silicate in phosphorite at the same time and a preparation method for the same. The catching agent preparation method comprises steps of mixinig 0.4 to 0.6 parts of C14 to C18 saturated fatty acid and 0.4 to 0.6 parts of oleic acid or linoleic acid, heating the mixture to the temperature of 80 to 100 DEG C, adding alkali liquor and stirring to saponify the mixture, controlling a pH value to be 8 to 9, saponifying for 50 to 70 minutes to achieve a semi-finished product, and adding 0.01 to 0.05 parts of polypropylene glycol and 0.01 to 0.05 parts of alkyl amino propionic acid to mix to achieve the catching agent. The catching agent can be applied to silicon calcium phosphate mines; reverse floatation of minerals of carbonate and silicate in the phosphorite can be achieved at the same time; and great selection effect can be achieved. Compared with the prior art, and removal process of carbonate and silicate minerals in the phosphorite and preparation of agents can be simplified by the use of the catching agent; and agent use amount and phosphorite floatation cost can be reduced.

Owner:HUBEI FORBON TECH

Self-activation flotation method for component of fluid inclusion of copper sulfide ore

The invention relates to a self-activation flotation method for a component of a fluid inclusion of a copper sulfide ore. Specific to the 'rich sulfur' state formed by surface relaxation of the copper sulfide ore, by utilizing the characteristics that copper ions released by the fluid inclusion of the copper sulfide ore have ultrahigh adsorption activity on a 'rich sulfur' surface, the copper ions of the component of the fluid inclusion are attached to a new surface of the copper sulfide ore so as to form a 'rich copper' surface, so that the adsorption activity of the surface of the copper sulfide ore to xanthate anions is increased, the self-activation flotation for the surface of the copper sulfide ore is realized, the flotation recovery of the copper sulfide ore is increased, the dosage of collecting agents is reduced and the technical and economic targets are increased.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

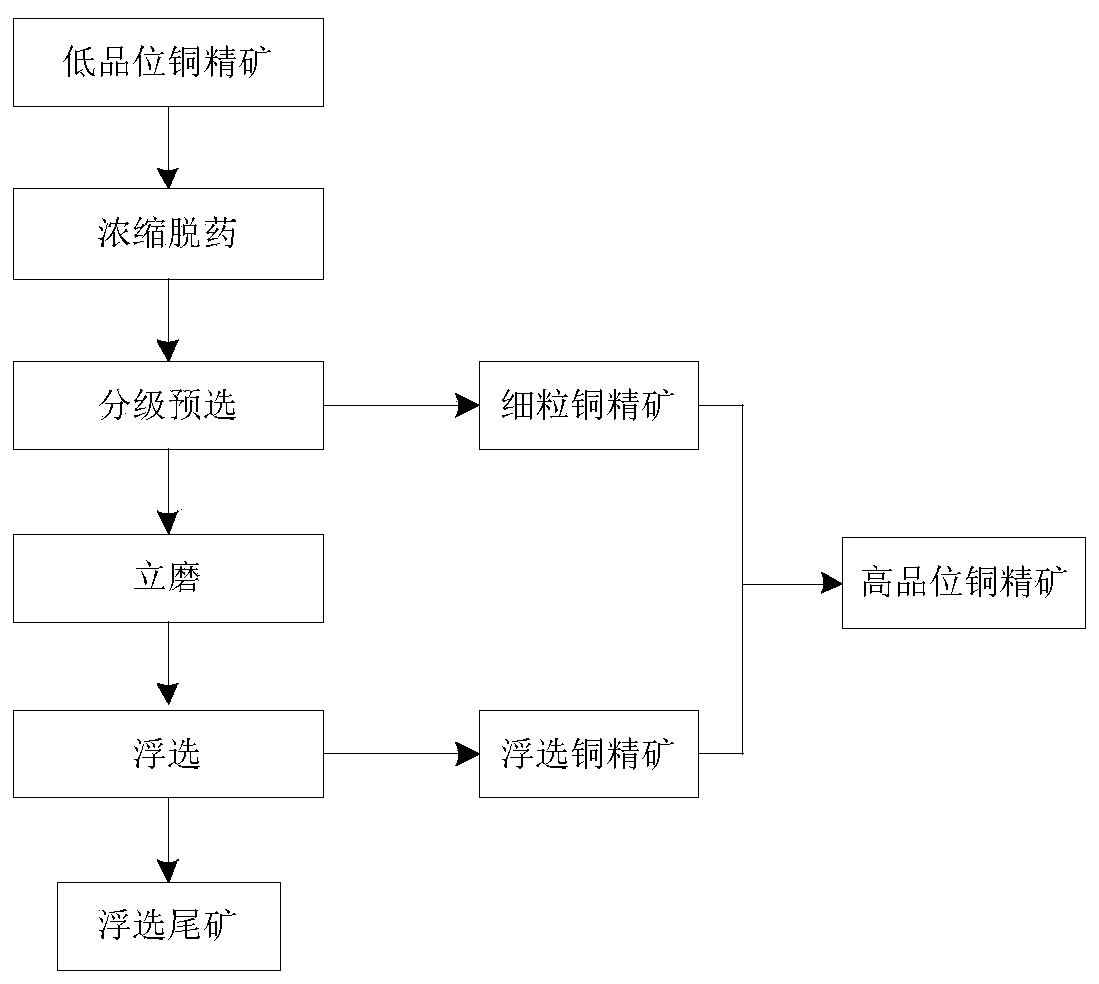

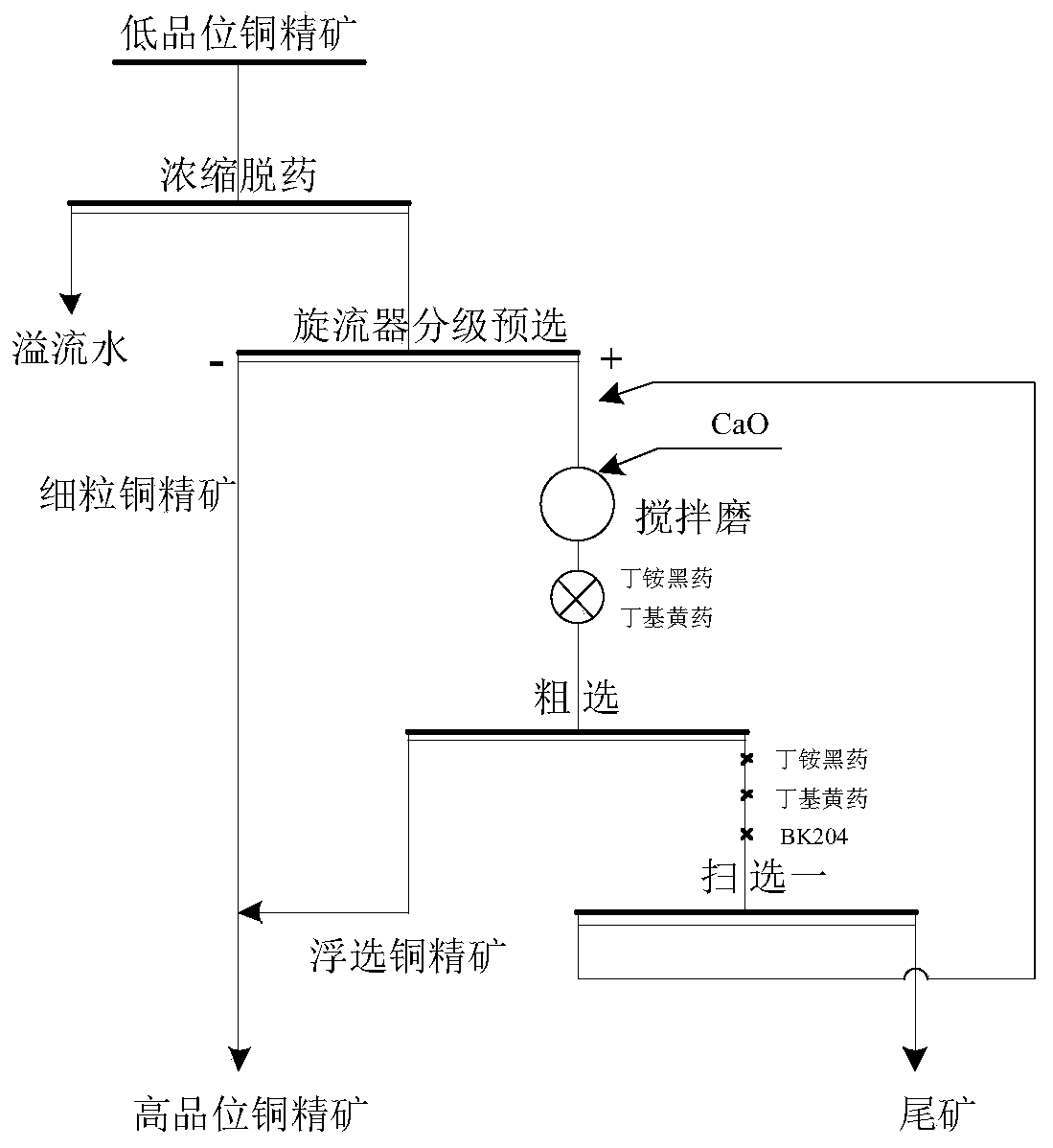

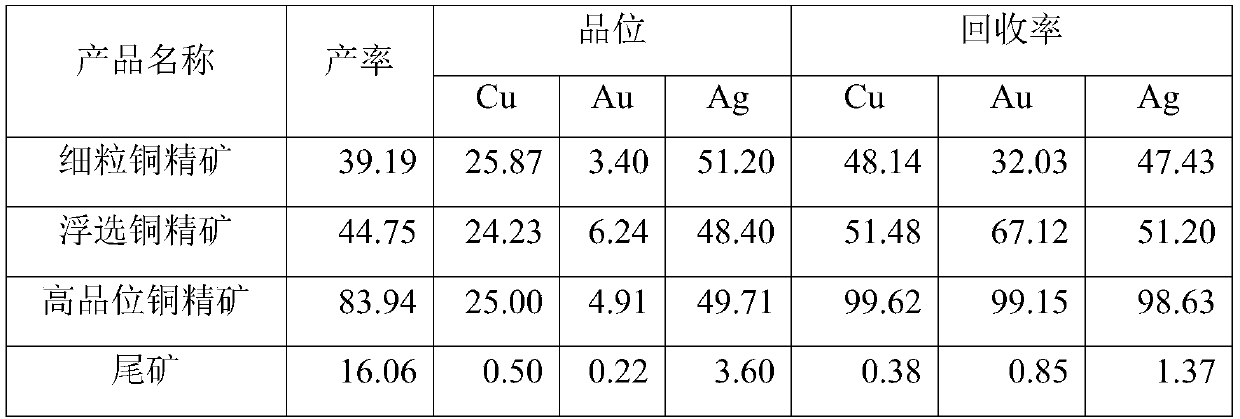

Novel graded preliminary dressing-mixing and grinding-flotation process for improving quality of copper concentrates

InactiveCN110560252AReduce grinding and floating treatment capacityReduce mineral processing costsWet separationCycloneCopper

The invention discloses a novel graded preliminary dressing-mixing and grinding-flotation process for improving the quality of copper concentrates. The process takes flotation copper concentrates as araw material, and comprises the following steps of concentrating to remove reagents, performing graded preliminary dressing, mixing and grinding ore, and performing copper flotation. Most residual dressing reagents in copper concentrate pulp are removed through concentration, and by using the characteristics that the copper concentrates are fine in grain and copper is enriched in fine fractions,the fine-fraction high-quality copper concentrations are obtained through graded preliminary separation by a cyclone, and settling sand is re-ground and re-dressed to realize the effective separationof impurity minerals and copper minerals, so that the purpose of improving the quality of the copper concentrations is achieved. The ore dressing process for improving quality of the copper concentrations is simple and effective, and has great significance in raising copper concentration sale price and reducing transportation cost. The process has the characteristics of simple flow, stable index and remarkable quality improving effect, and is beneficial for being applied and popularized in similar mines.

Owner:JIANGXI COPPER CORP

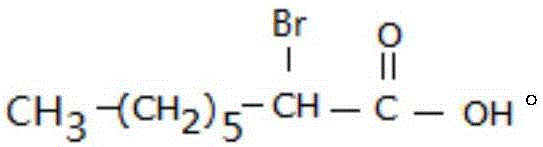

Multi-polar-group non-vulcanized ore flotation combined collecting agent and preparation and use method thereof

The invention belongs to the technical field of mineral processing, and particularly relates to a multi-polar-group non-vulcanized ore flotation combined collecting agent and a preparation and use method thereof. The multi-polar-group non-vulcanized ore flotation combined collecting agent is prepared from the following components in mass percentage: 82-94% of 1-octoxyl 5-carboxyl para-decyl amine, 3-9% of alpha-bromo-octanoic acid and 3-9% of 3-octoxyl propylamine. The multi-polar-group non-vulcanized ore flotation combined collecting agent disclosed by the invention is used for reverse flotation of quartz with hematite iron ore, direct flotation of CaF2 with fluorite ore and direct flotation of apatite with phosphorite, is good in selectivity and high in collecting performance, and can realize effective separation of target minerals from other minerals.

Owner:NORTHEASTERN UNIV

Coal flotation capsule slow-release collecting agent and preparation method and application thereof

ActiveCN114471956AImprove adsorption capacityEnhanced inhibitory effectFlotationActive agentCombinatorial chemistry

The invention discloses a coal flotation capsule slow-release collecting agent as well as a preparation method and application thereof. The collecting agent comprises a collecting agent, a functional agent and an emulsifier, wherein the collecting agent comprises the following components: diesel oil, pine oil and oleic acid ester; the functional medicament is formed by mixing a water glass solution and a sulfuric acid solution in proportion; and the emulsifier is a nonionic surfactant. Compared with a conventional collecting agent, the capsule slow-release collecting agent is of a special capsule structure and has the dual effects of collecting and selective inhibition; when a collecting agent capsule shell acts on a coal molecule hydrophobic point, an original capsule structure collapses, an inhibitor component of a capsule inner core is released, and when a collecting agent does not act on coal molecules, an inhibitor is temporarily sealed and stored by the collecting agent. And due to slow release of the inhibitor, excessive consumption in a short time is avoided, the problem that the inhibition effect becomes poor along with reduction of the concentration of the inhibitor is solved, and the capsule slow-release collecting agent is higher in selectivity and has a wide application prospect.

Owner:CHINA UNIV OF MINING & TECH

A slurry-driven stirring flotation equipment with self-adjusting slurry and self-defoaming functions

The invention relates to the field of coal slurry pulp conditioning flotation treatment, in particular to pulp drive agitating type flotation equipment with self pulp conditioning and self defoaming functions. The pulp drive agitating type flotation equipment at least comprises a flotation tank and a drive agitating mechanism; the feeding end of the drive agitating mechanism is of a fork structure, one inlet end of the drive agitating mechanism is communicated with a double-sleeve jet flow assembly used for jet flow of flotation reagents, and the other inlet end is communicated with a flotation feeding pressure buffer tank; bubble overflow grooves are formed in the two side tank walls in the length direction of the flotation tank, and are formed in the outer side wall of the tank wall of the flotation tank, and an overflow wall is formed through the outer side wall of the tank wall of the flotation tank; at least one layer of defoaming screen plate for defoaming is horizontally arranged in a groove body of each bubble overflow groove; and the equipment further comprises a defoaming spraying head and a tailing box. The equipment has the beneficial effects that bubble mineralization is easier, a foam layer is more stable, and the defoaming process is more rapid; the concentrate taste can be effectively improved, and meanwhile great convenience is provided for transportation of subsequently-transported flotation foam.

Owner:ANHUI UNIV OF SCI & TECH

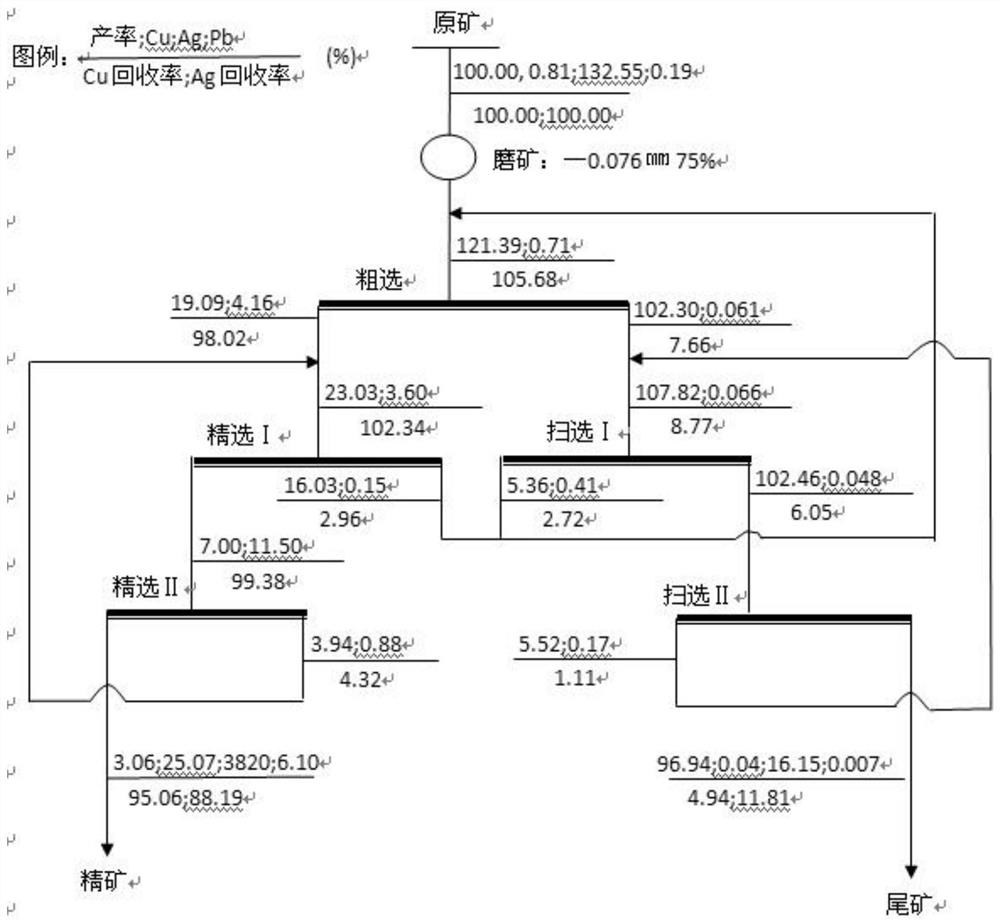

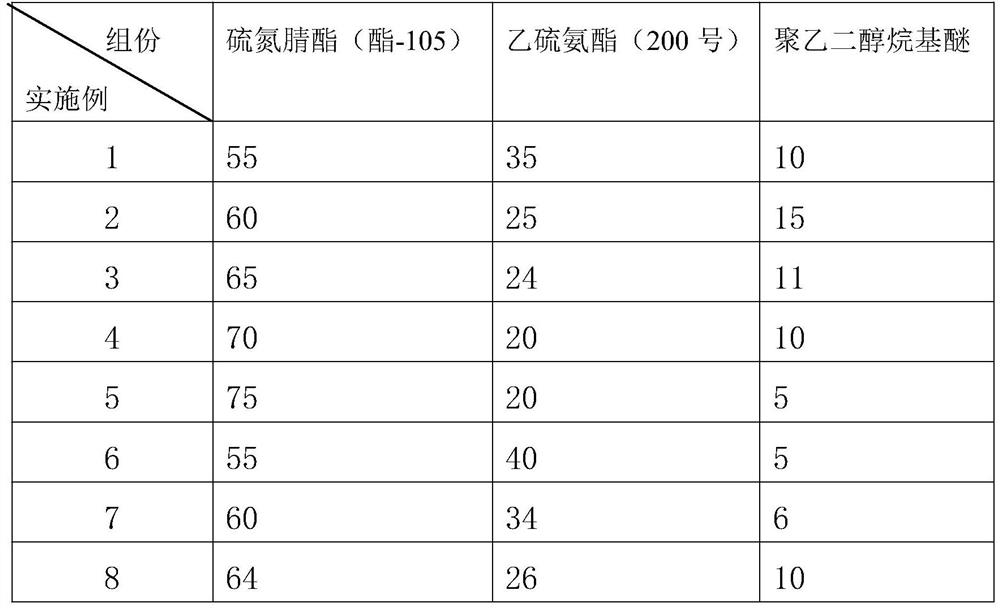

Collecting agent for flotation of complex and difficult-to-treat copper-silver sulfide ore

PendingCN114210462ANo pollutionSolve the technical problems of beneficiation that are difficult to use efficientlyFlotationFoaming agentCopper sulfide

The invention discloses a collecting agent for flotation of complex and difficult-to-treat copper sulfide silver ore, which is prepared by mixing the following components in percentage by mass: 55 to 75 percent of sulfur nitrogen nitrile ester, 20 to 40 percent of ethionine ester and 5 to 15 percent of polyethylene glycol alkyl ether. The collecting agent disclosed by the invention not only has very strong collecting performance, but also has foamability, so that the cost of a foaming agent can be saved in production; due to the fact that the collecting agent MT-23 is high in capacity, the total consumption of the agent per ton of ore is extremely low; the flotation cost is saved by more than 25% compared with that of an existing agent; the collecting agent is non-toxic, odorless and easy to degrade, belongs to a green and environment-friendly mineral separation collecting agent, and has a wide popularization prospect. By the adoption of the method, the recovery rate of copper and silver can be remarkably increased on the premise that the quality of copper-silver concentrate products is guaranteed, and the method has the advantages of being simple in technological process, stable, reliable, high in applicability, simple in reagent system, small in reagent dosage, convenient to add and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com