Flotation device and method for removing free carbon in silicon carbide powder

A technology of silicon carbide powder and flotation device, which is applied in flotation, solid separation and other directions, can solve the problems of poor device stability, reduced flotation efficiency, and high labor intensity, and achieves convenient operation, improved flotation efficiency, and reduced labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

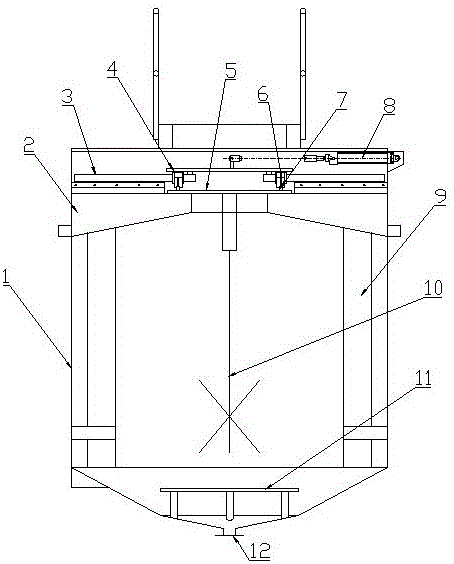

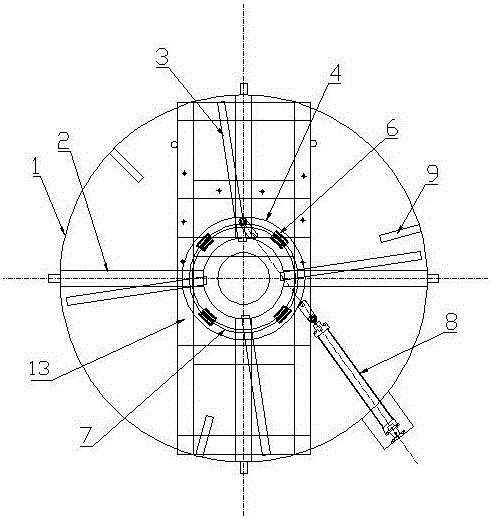

[0023] Embodiment 1, with reference to figure 1 and figure 2 , a flotation device for removing free carbon in silicon carbide powder, comprising a tank body 1 and a stirring device 10 arranged in the tank body 1, the stirring device 10 is connected to the tank body 1 through a fixing frame 13 on the top of the tank body 1 Then, the top of the tank body 1 is provided with a material inlet, the bottom of the tank body 1 is provided with a material outlet 12, and the tank body 1 between the material outlet 12 and the stirring device 10 is provided with a bubble generator 11, and the tank near the material inlet A foam scraping device is provided between the inner wall of the body 1 and the stirring device 10, and the foam scraping device includes a foam collection tank 2 arranged radially along the tank body 1 and a rotating scraper 3 matched with the foam collection tank 2. The scraper 3 is arranged on one side of the foam collection tank 2, the outer end of the foam collectio...

Embodiment 2

[0024] Embodiment 2, the flotation device for removing free carbon in silicon carbide powder described in embodiment 1: a rotating guiding mechanism is provided between the rotating seat 4 and the fixed seat 5, and the rotating guiding mechanism includes a fixed The annular guide rail 7 on the seat 5 and the roller 6 that cooperates with the annular guide rail 7, the roller 6 is contained on the rotating seat 4, improves the stability of the whole device, makes the rotation of the rotary scraper more flexible.

Embodiment 3

[0025] Example 3, the flotation device for removing free carbon in silicon carbide powder described in Example 2: four rollers 6 are provided, which are evenly distributed along the circumference of the rotating base 4 to ensure the stability of the rotating base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com