Efficient ore dressing method for bertrandite

A beneficiation method and hydroxysilicon beryllium technology, applied in flotation, solid separation and other directions, can solve the problems of low grade, complex ore properties, complex gangue composition, etc., and achieve high enrichment ratio, simple process flow, and high economic promotion. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

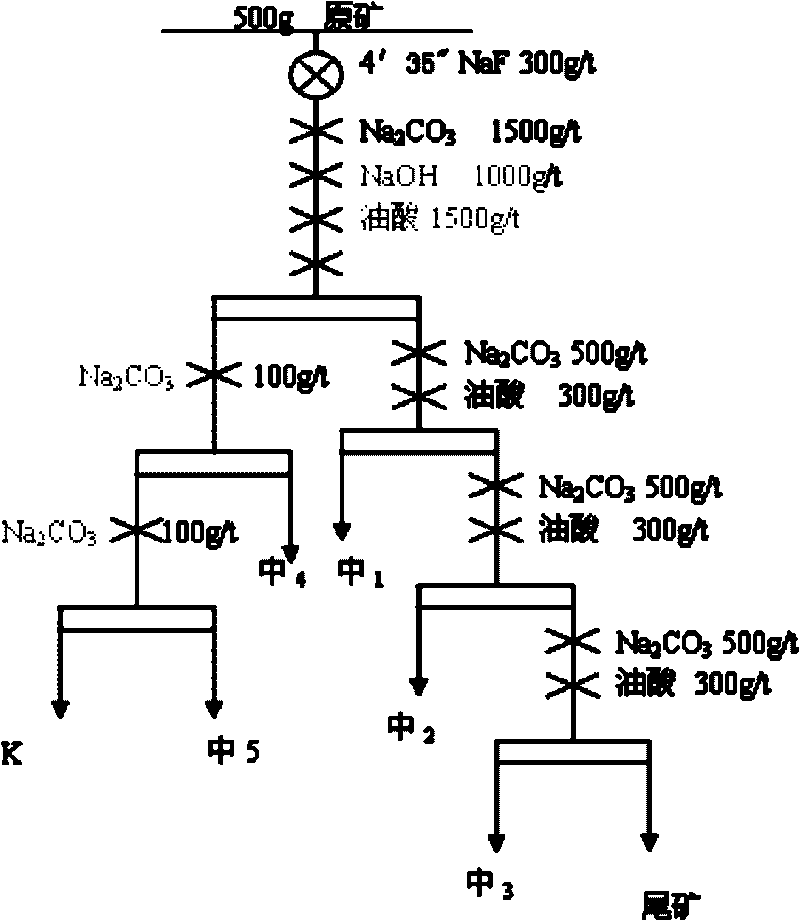

[0030] Embodiment 1: Actual ore open circuit test

[0031] Taking a beryllium ore in Xinjiang as the test object, the process flow chart used in the test is shown in figure 1 , the test results are shown in Table 1.

[0032] Table 1 Open circuit test results

[0033] product name

[0034] It can be seen from the results that the concentrate grade can reach 3.38%, the coarse concentrate recovery rate is 69.35%, and the concentrate + medium ore recovery rate can reach 92.11%.

Embodiment 2

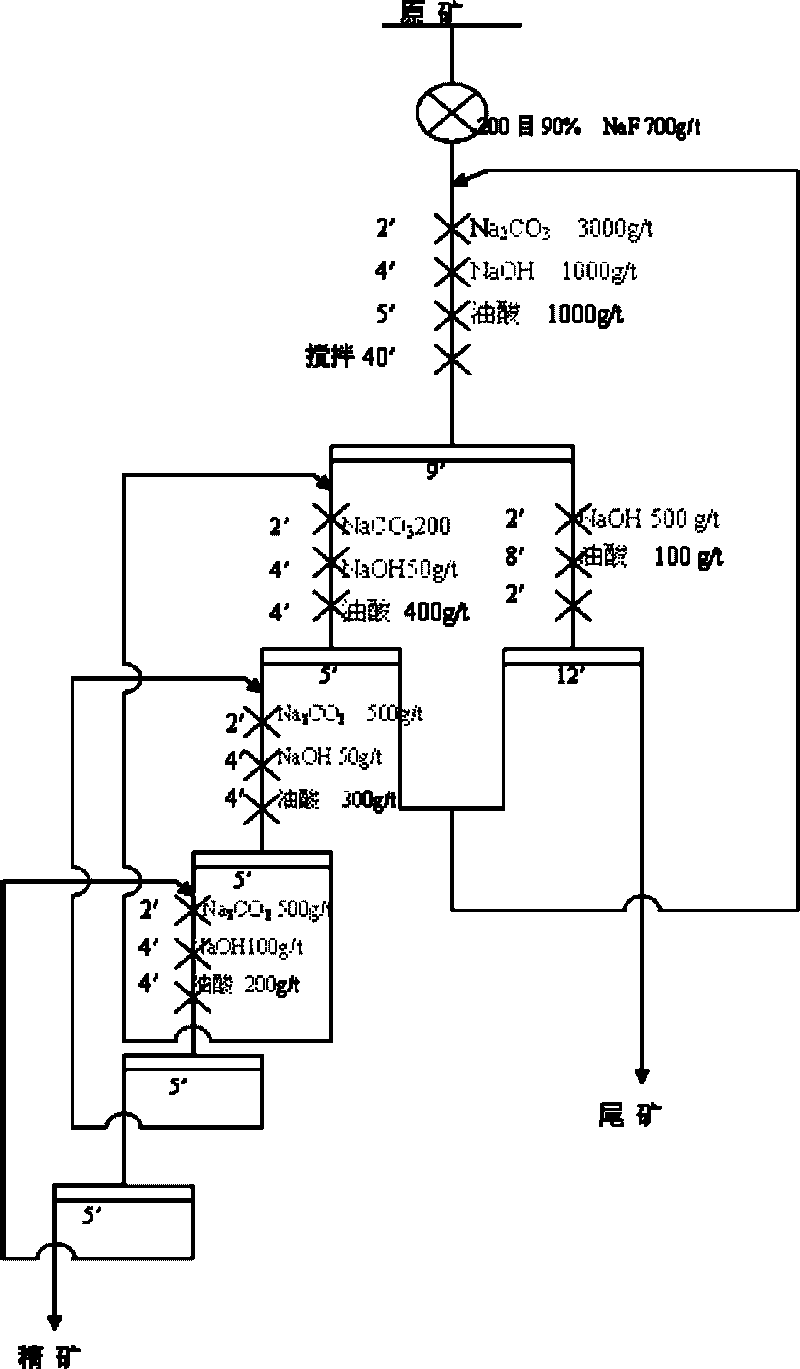

[0035] Example 2: Small-scale closed-circuit test of actual ore in a beryllium mine in Xinjiang

[0036] In order to eliminate the influence of difficulties in flotation separation of middle ore, a small closed-circuit test was carried out on a certain beryllium ore in Xinjiang. For the process flow used in the test, see figure 2 , the results are shown in Table 2.

[0037] Table 2 Small closed circuit test results

[0038] product name

[0039] It is found that only 0.16% of the raw ore can be obtained, and the concentrate grade can reach 3.21%, and the recovery rate can reach 85.18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com