Mehtod for producing zinc concentrate and lead concentrate using zinc oxide ore and zinc slag

A technology for zinc oxide ore and zinc concentrate, which is applied in the fields of lead-zinc beneficiation and solid waste recycling, can solve the problems of shortened anode life, reduced zinc quality, waste of resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

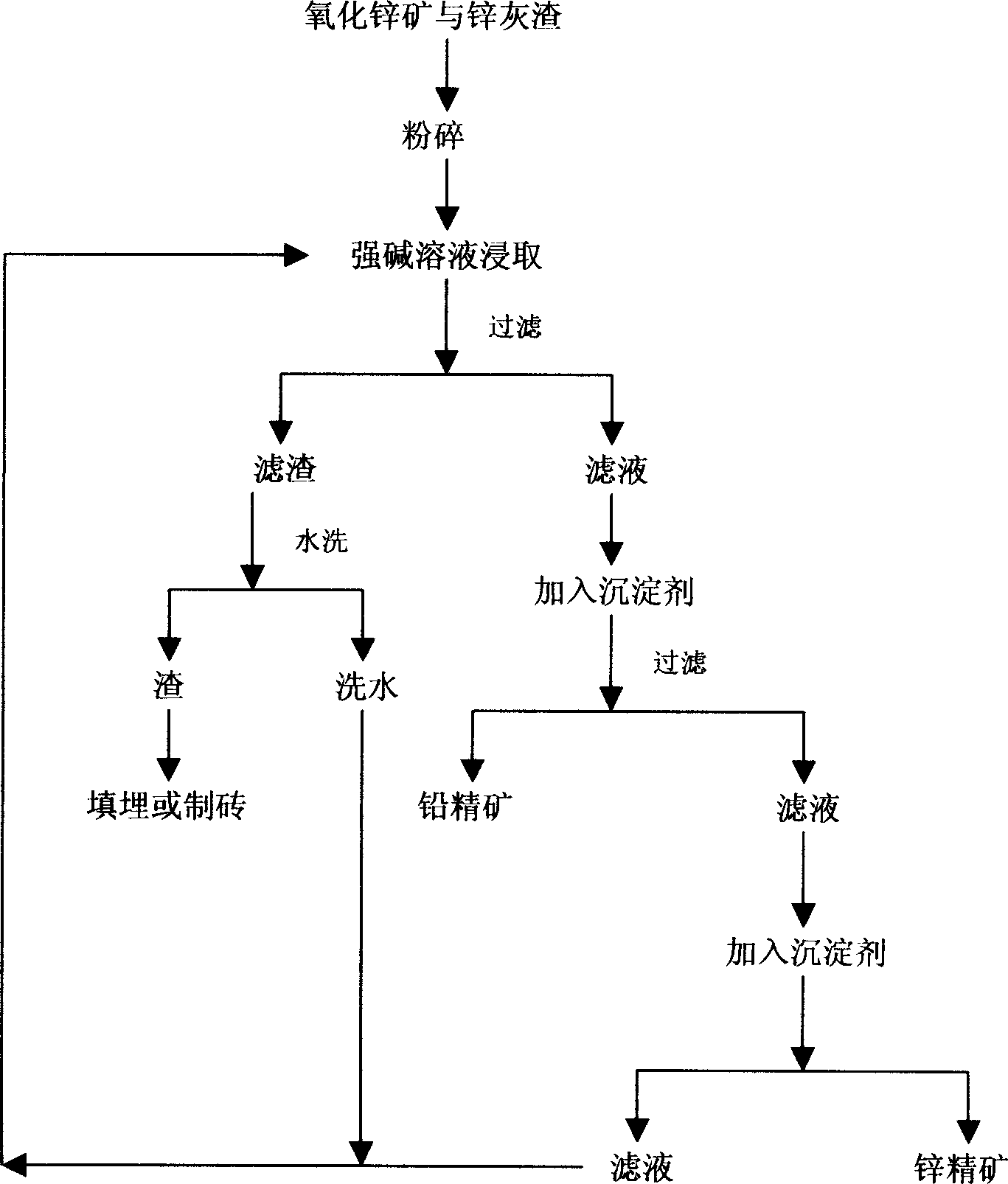

[0019] Please refer to the attached figure 1 . Using a low-grade zinc oxide ore as raw material, the zinc grade is 13.8, the lead grade is 4.6, and the zinc is mainly smithsonite (ZnCO 3 ), Willemite (ZnSiO 4 ) form, lead as white lead ore (PbCO 3 ) and lead alum (PbSO 4 ) form, these lead-zinc components have high solubility in strong alkaline solution. After the raw material is ground to a particle size of 0.1-1mm, put 1t of raw material into 3.5-5m 3 For industrial caustic soda solution, the leaching temperature is controlled at 10-95°C, the concentration of industrial caustic soda solution is 200-400g / L, and the reaction is carried out under the condition of slow stirring at 120 rpm for 90 minutes. Since most metals cannot be dissolved in strong alkali solution, iron, manganese, copper, calcium and other metals in zinc oxide ore will precipitate in the filter residue in the form of hydroxide, and the filtrate is only zinc, lead and a small amount of aluminum . The e...

Embodiment 2

[0021] Using zinc dust from a steelmaking plant as raw material, its chemical composition is as follows:

[0022] Element

[0023]Zinc dust particle size is all less than 1mm, and within the particle size required by the present invention, no pretreatment is needed, and it is directly leached with sodium hydroxide solution: immerse 1 ton of zinc dust in 3 cubic meters of sodium hydroxide solution and feed, leaching The temperature is controlled at 10-95° C., the concentration of sodium hydroxide solution is 250 g / L, and the extraction rates of zinc and lead are both 100 percent after reacting for 100 minutes under the condition of slow stirring at 120 rpm. Filter while it is hot, wash the filter residue with water and discharge it to make bricks or landfill, and wash the water for reuse. Add precipitant in the filtrate containing zinc and lead obtained after filtering, precipitant is ammonium sulfide, the addition of precipitant is added by 2 times mass ratio of lea...

Embodiment 3

[0025] Zinc and lead concentrates are produced from Guizhou lead-zinc ore and hot-dip galvanizing plant zinc ash. The chemical composition of lead-zinc ore and zinc ash is as follows:

[0026] chemical composition

PbO

ZnO

CaO

MgO

Fe 2 o 3

K 2 o

Na 2 o

SiO 2

Al 2 o 3

MnO

TiO 2

Content %

3.46

7.63

1.78

1.24

32.30

0.78

0.024

19.43

10.21

0.20

0.61

[0027] Element

Zn

Fe

Pb

Al

Cl

Cu

Content %

55.21

1.4~2.0

2~3

0.015

20~30

0.965

[0028] Although zinc ash has a high zinc content, it is a kind of zinc waste residue that has great recovery value and is difficult to handle due to the complex impurity components, especially the high chlorine content. The lead-zinc oxide ore used in this example has low zinc content and is difficult to handle with tradit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com