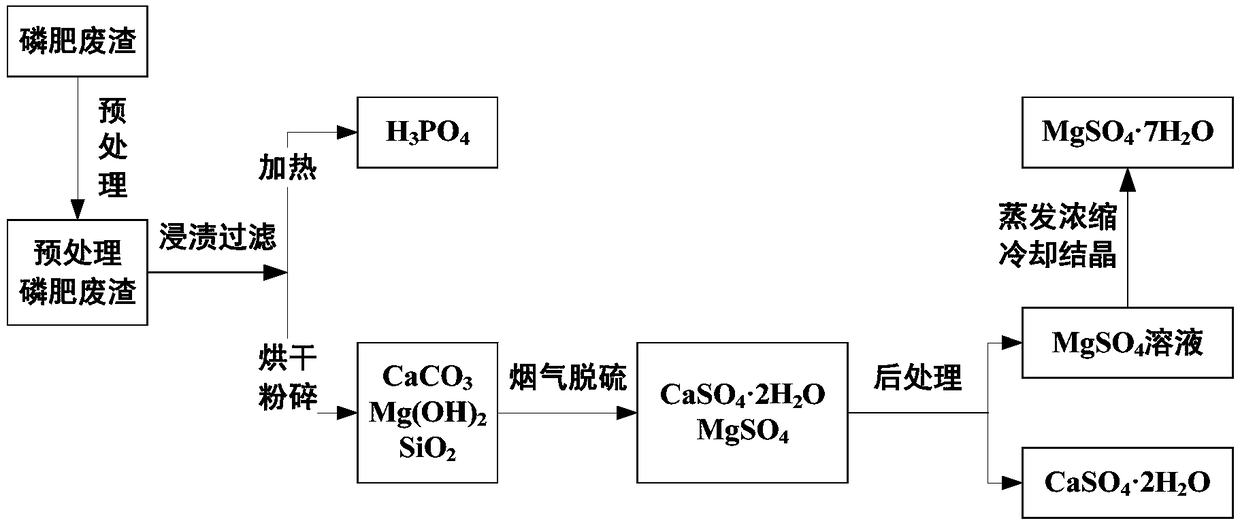

Desulfurization and resource utilization method of phosphorus fertilizer waste residues

A phosphate fertilizer waste residue and resource utilization technology, applied in chemical instruments and methods, separation methods, phosphoric acid and other directions, can solve problems such as dust flying, pollution of surface water and groundwater, land occupation, etc., achieve significant economic benefits, realize resource utilization, Significant social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The phosphate fertilizer waste residue is dried and crushed to below 300 mesh to obtain the pretreated phosphate fertilizer waste residue. According to the ratio of 10mL deionized water / 1g pretreated phosphate fertilizer waste residue, add deionized water and pretreated phosphate fertilizer waste residue into the soaking tank successively, stir at room temperature for 12 hours, filter with a centrifuge to obtain impregnation liquid and filter cake, and heat the impregnation liquid to 80 Keep at ℃ for 60min to obtain phosphoric acid. The filter cake, that is, the phosphate fertilizer waste residue, is dried and pulverized, and sent to the slurry tank. Add water and stir continuously to form a slurry with a solid content of 25%, and heat it to 60°C to obtain an absorption liquid. Keep the pH value of the absorption liquid at 7, and regularly discharge the sediment at the bottom of the tank. The absorption liquid is atomized by the nozzle and pumped into the absorption tow...

Embodiment 2

[0061] The phosphate fertilizer waste residue is dried and crushed to below 300 mesh to obtain the pretreated phosphate fertilizer waste residue. According to the ratio of 40mL deionized water / 1g pretreated phosphate fertilizer waste residue, add deionized water and pretreated phosphate fertilizer waste residue into the impregnation tank successively, stir at room temperature for 24 hours, filter with a centrifuge to obtain impregnation liquid and filter cake, and heat the impregnation liquid to 70 Keep at ℃ for 60min to obtain phosphoric acid. The filter cake, that is, the phosphate fertilizer waste residue, is dried and pulverized, and sent to the slurry tank, adding water and continuously stirring to form a slurry with a solid content of 20%, heating to 30°C to obtain an absorption liquid, keeping the pH value of the absorption liquid at 8, and regularly discharging the sediment at the bottom of the tank. The absorption liquid is atomized by the nozzle and pumped into the a...

Embodiment 3

[0064] The phosphate fertilizer waste residue is dried and crushed to below 300 mesh to obtain the pretreated phosphate fertilizer waste residue. According to the ratio of 20mL deionized water / 1g pretreated phosphate fertilizer waste residue, add deionized water and pretreated phosphate fertilizer waste residue into the impregnation tank successively, stir at room temperature for 36 hours, filter with a centrifuge to obtain impregnation liquid and filter cake, and heat the impregnation liquid to 60 Keep at ℃ for 30min to get phosphoric acid. The filter cake, that is, the phosphate fertilizer waste residue, is dried and pulverized, and sent to the slurry tank. Add water and stir continuously to form a slurry with a solid content of 15%, and heat it to 50°C to obtain an absorption liquid. Keep the pH value of the absorption liquid at 6, and regularly discharge the sediment at the bottom of the tank. The absorption liquid is atomized by the nozzle and then pumped into the absorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com