A discharge, collection and recycling method of the electrolyte of the wasted accumulator

A waste battery and electrolyte technology, which is applied in the field of electrolyte pouring, collection and recycling, can solve the problems of low recycling and comprehensive utilization of electrolyte solution, increase investment, pollute environmental groundwater resources, etc., and achieve huge environmental benefits and Social benefit, less system investment, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

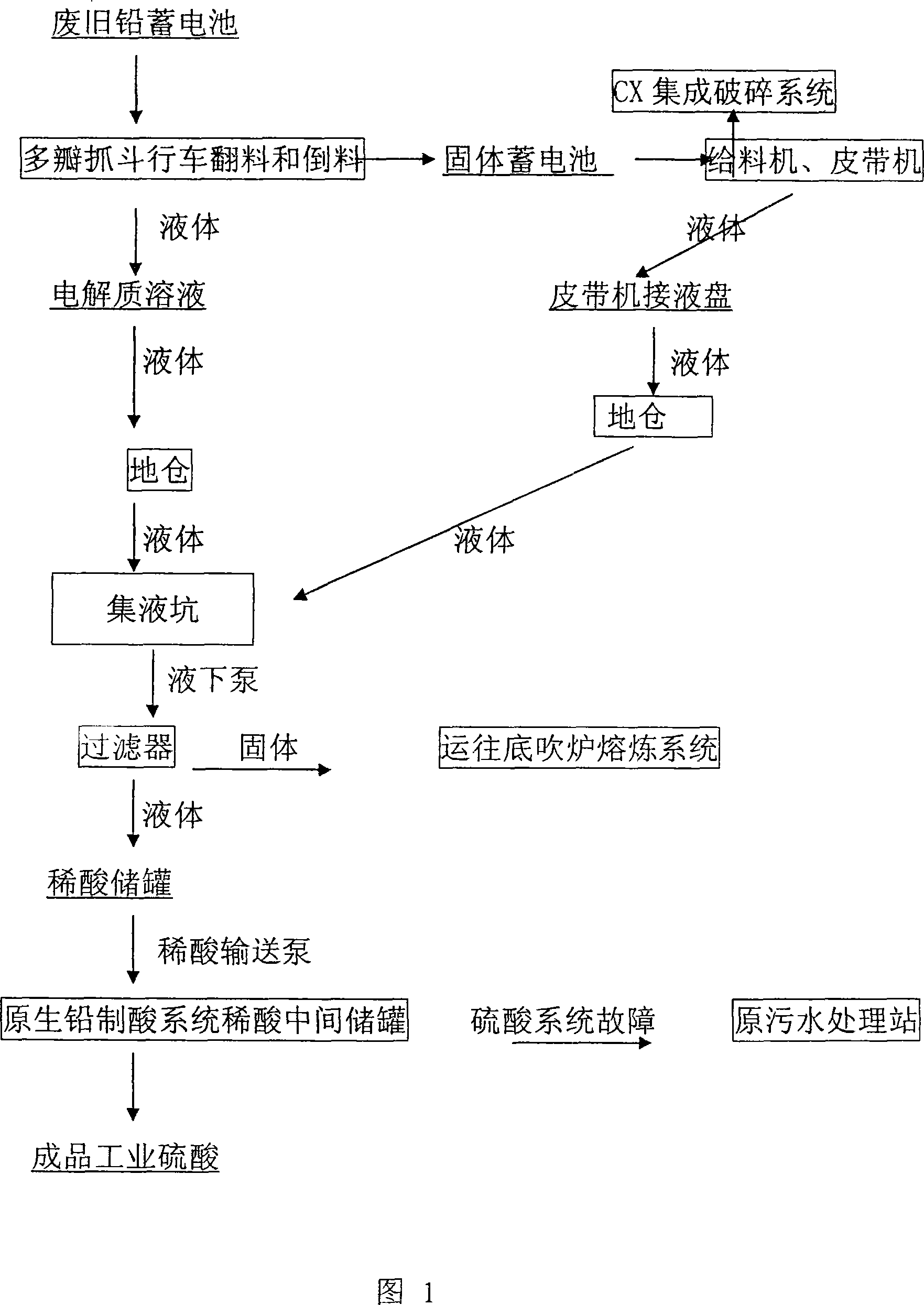

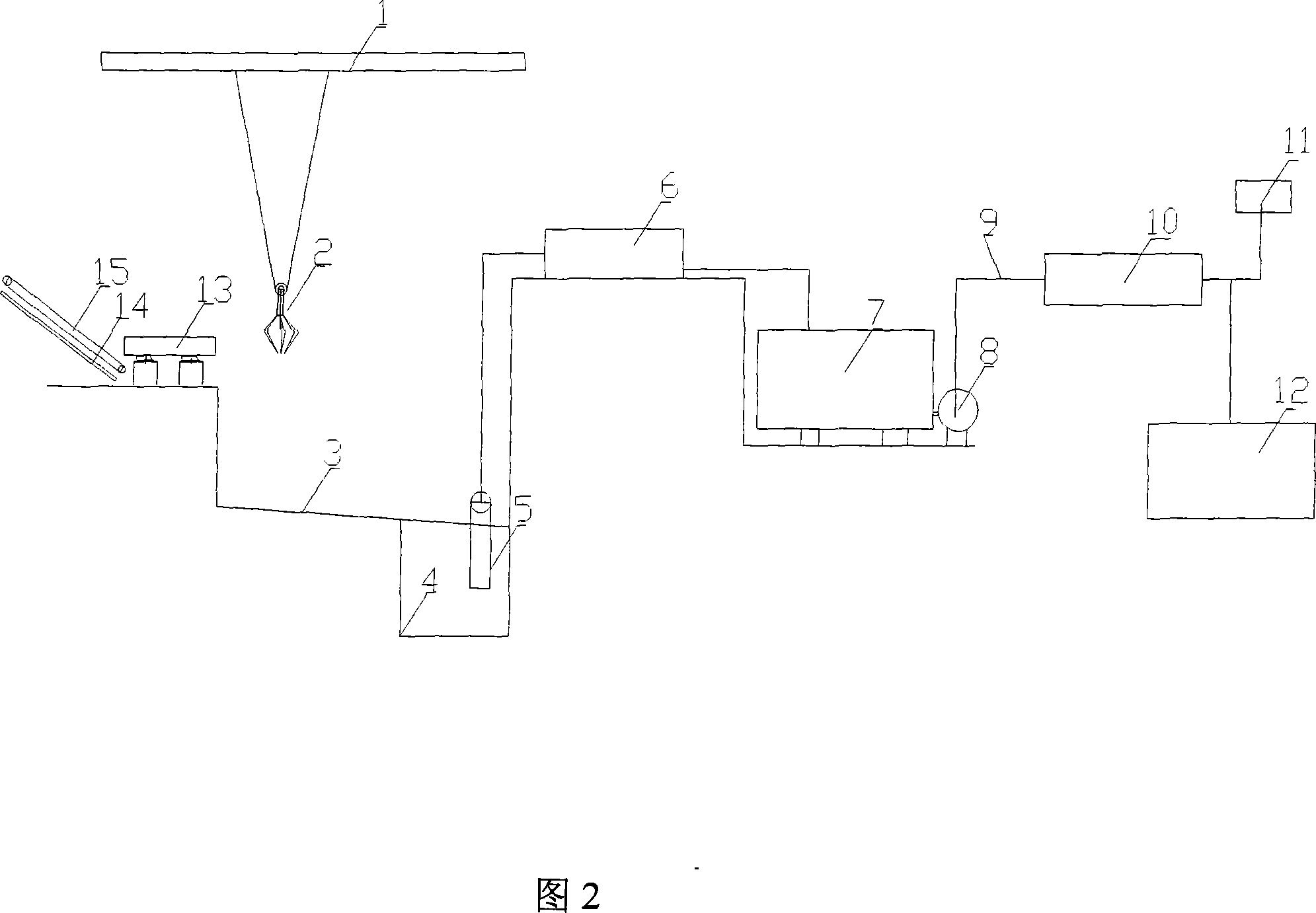

[0023] As shown in Figures 1 and 2, a kind of waste storage battery electrolyte of the present invention pours out, collects and recycles the method, specifically as follows:

[0024] Step 1: Turn over and dump the recovered aluminum batteries in the basement by using a hydraulic grab. During the process of lifting the battery, the battery shell is broken or broken, and part of the electrolyte solution flows out to the ground. Dicangli,

[0025] Step 2: Send the broken or broken battery case to the vibrating feeder, so that part of the electrolyte that has not flowed out will flow out under the vibration of the vibrating feeder when feeding, and this part of the liquid will pass through the feeding belt At the time, the liquid is collected in the liquid receiving pan at the lower part of the belt conveyor, flows to the tail of the belt conveyor, and then collects in the ground chamber.

[0026] Step 3: Collect all the electrolyte into the sump at the lowest part of the baseme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com