Microbial fly ash building material and preparation method thereof

A technology of microorganisms and fly ash, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high processing costs, inability to consume fly ash on a large scale, and high processing costs of melting and solidification technology, and achieve significant environmental protection Benefits and social benefits, good practical application value, and high utilization rate of solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

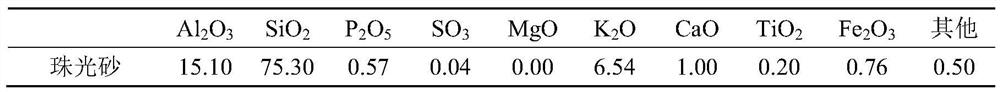

Embodiment 1

[0048] 50 parts of waste incineration fly ash, 2 parts of silica powder, 30 parts of fly ash, 3 parts of cement, 15 parts of slaked lime, 10 parts of 50-80 mesh pearlescent sand, 10 parts of bacterial liquid, 2 parts of pure acrylic emulsion, 5 parts of red mud , 9 parts of steel slag powder, 1 part of potassium metasilicate, 0.05 part of polyacrylamide, 0.1 part of KH570 silane coupling agent.

[0049] The bacterial liquid adopts the bacterial liquid obtained by screening, activating and culturing the microbial KJ01 strain.

[0050] The crushing index of the prepared ceramsite is 26%, the water absorption rate is 1.7%, and the mass loss corresponding to the firmness index is 12.5%.

Embodiment 2

[0052] 70 parts of waste incineration fly ash, 10 parts of silica powder, 20 parts of fly ash, 5 parts of cement, 10 parts of slaked lime, 30 parts of 50-80 mesh pearlescent sand, 40 parts of bacterial liquid, 4 parts of pure acrylic emulsion, 8 parts of red mud , 7 parts of steel slag powder, 20 parts of nutrient solution, 0.5 part of potassium silicate, 0.2 part of polyacrylamide, 0.5 part of KH570 silane coupling agent.

[0053] The bacterial liquid adopts the bacterial liquid obtained by screening, activating and culturing the microbial KJ01 strain.

[0054] The crushing index of the prepared ceramsite is 19%, the water absorption rate is 1.9%, and the mass loss corresponding to the firmness index is 7.6%.

Embodiment 3

[0056] 50 parts of waste incineration fly ash, 2 parts of silica powder, 25 parts of fly ash, 3 parts of cement, 15 parts of hydrated lime, 10 parts of 50-80 mesh pearlescent sand, 10 parts of bacterial liquid, 2 parts of pure acrylic emulsion, 6 parts of red mud , 8 parts of steel slag powder, 10 parts of nutrient solution, 0.8 part of potassium metasilicate, 0.1 part of polyacrylamide, and 0.1 part of KH570 silane coupling agent.

[0057] The bacterial liquid is obtained by screening, activating and culturing microbial carbonic anhydrase strains.

[0058] The crushing index of the prepared ceramsite is 14%, the water absorption rate is 1.2%, and the mass loss corresponding to the firmness index is 5.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com