Novel graded preliminary dressing-mixing and grinding-flotation process for improving quality of copper concentrates

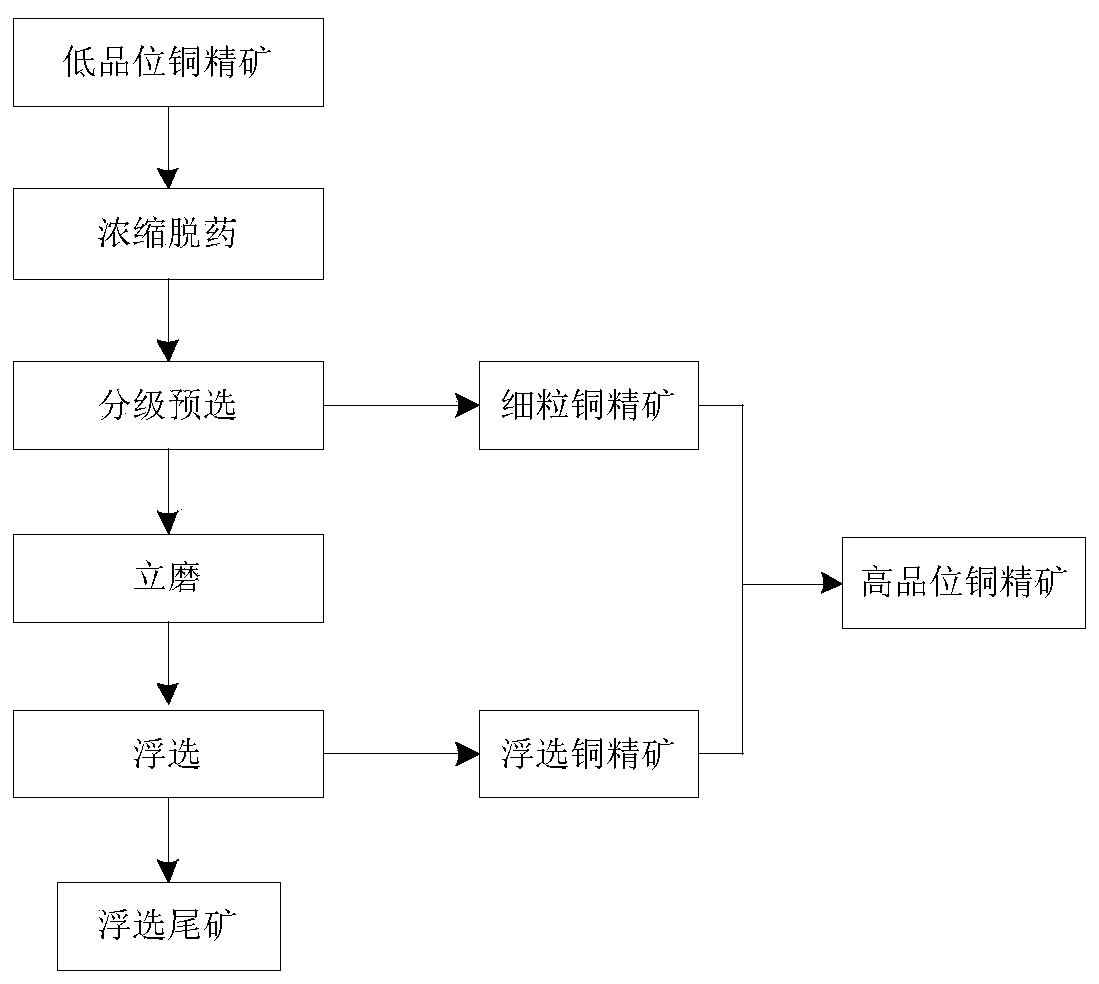

A technology for copper concentrate and stirring mill, which is applied in the new process field of classification pre-selection-stirring mill-flotation for upgrading copper concentrate, can solve the disadvantage of comprehensive recovery of rare and precious associated elements, increase the dosage of inhibitors such as lime, and the dosage of lime It can reduce the cost of beneficiation, reduce the cost of flotation, and reduce the cost of grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

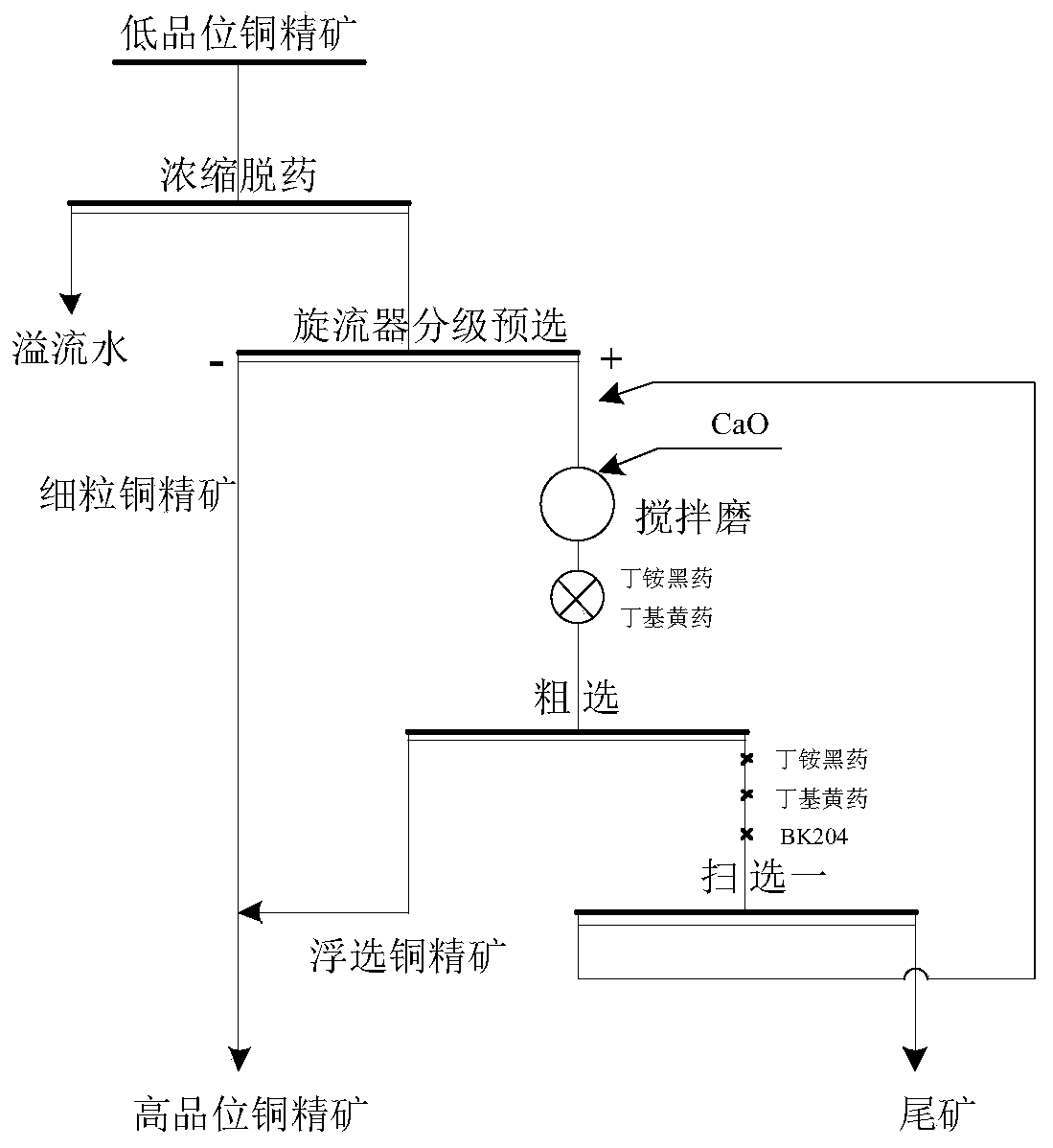

Method used

Image

Examples

Embodiment 1

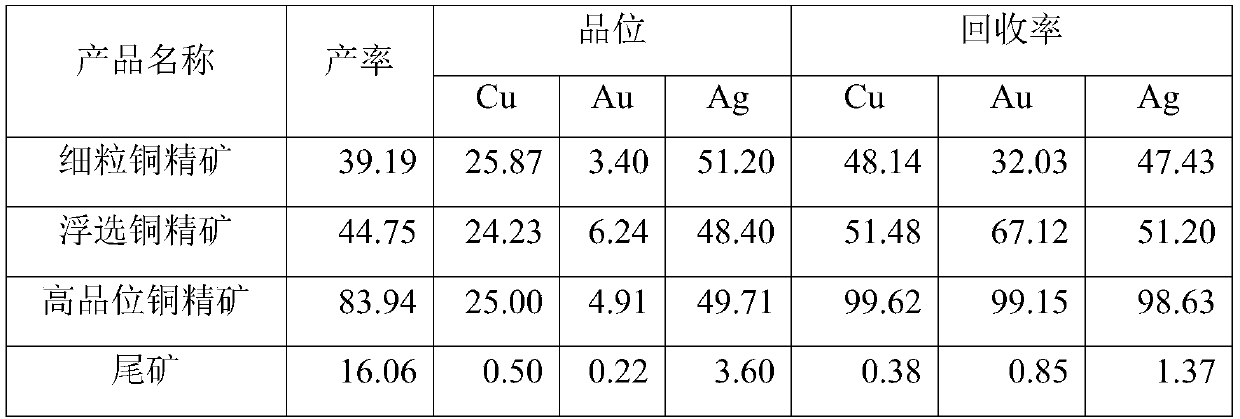

[0050]The copper grade in the copper concentrate in this embodiment is 21.06%, the associated gold and silver contents are 4.16g / t and 42.30g / t respectively, the copper minerals are mainly chalcopyrite, and the impurity minerals are mainly pyrite. There is also a small amount of gangue minerals with a fineness of -0.038mm, accounting for about 54.36%. The concrete steps that adopt technique of the present invention are as follows:

[0051] (1) The industrial test took the flotation copper concentrate pulp after the separation of copper and molybdenum on site. The pulp concentration was 42.50%. A Φ30m thickener was used for concentration, dehydration and drug removal. The concentration of the underflow of the thickener was 65.40%.

[0052] (2) Add water to the underflow of the thickener and stir to adjust the pulp, and adjust the pulp concentration to 28%.

[0053] (3) After the copper concentrate slurry is adjusted, it is pumped into a Φ150mm hydrocyclone for classification a...

Embodiment 2

[0064] The copper grade in the copper concentrate in this embodiment is 24.14%, the associated gold and silver contents are 3.42g / t and 36.90g / t respectively, the copper minerals are mainly chalcopyrite, and the impurity minerals are mainly pyrite. There is also a small amount of gangue minerals with a fineness of -0.038mm, accounting for about 56.07%. The concrete steps that adopt technique of the present invention are as follows:

[0065] (1) The industrial test took the flotation copper concentrate pulp after the separation of copper and molybdenum on site. The pulp concentration was 44.25%. A Φ30m thickener was used for concentration, dehydration and drug removal. The concentration of the underflow of the thickener was 67.20%.

[0066] (2) Add water to the underflow of the thickener and stir to adjust the pulp, and adjust the pulp concentration to 28%.

[0067] (3) After the copper concentrate slurry is adjusted, it is pumped into a Φ150mm hydrocyclone for classification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com