Method for removing titanium minerals in high-sulfur bauxite

A high-sulfur bauxite and titanium mineral technology, applied in solid separation, flotation and other directions, can solve the problems of alumina dissolution and high titanium mineral content in unfavorable bauxite, and achieve good economic and technical indicators, low impurity content, The effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments, so that those skilled in the art can better understand and implement the technical solutions of the present invention.

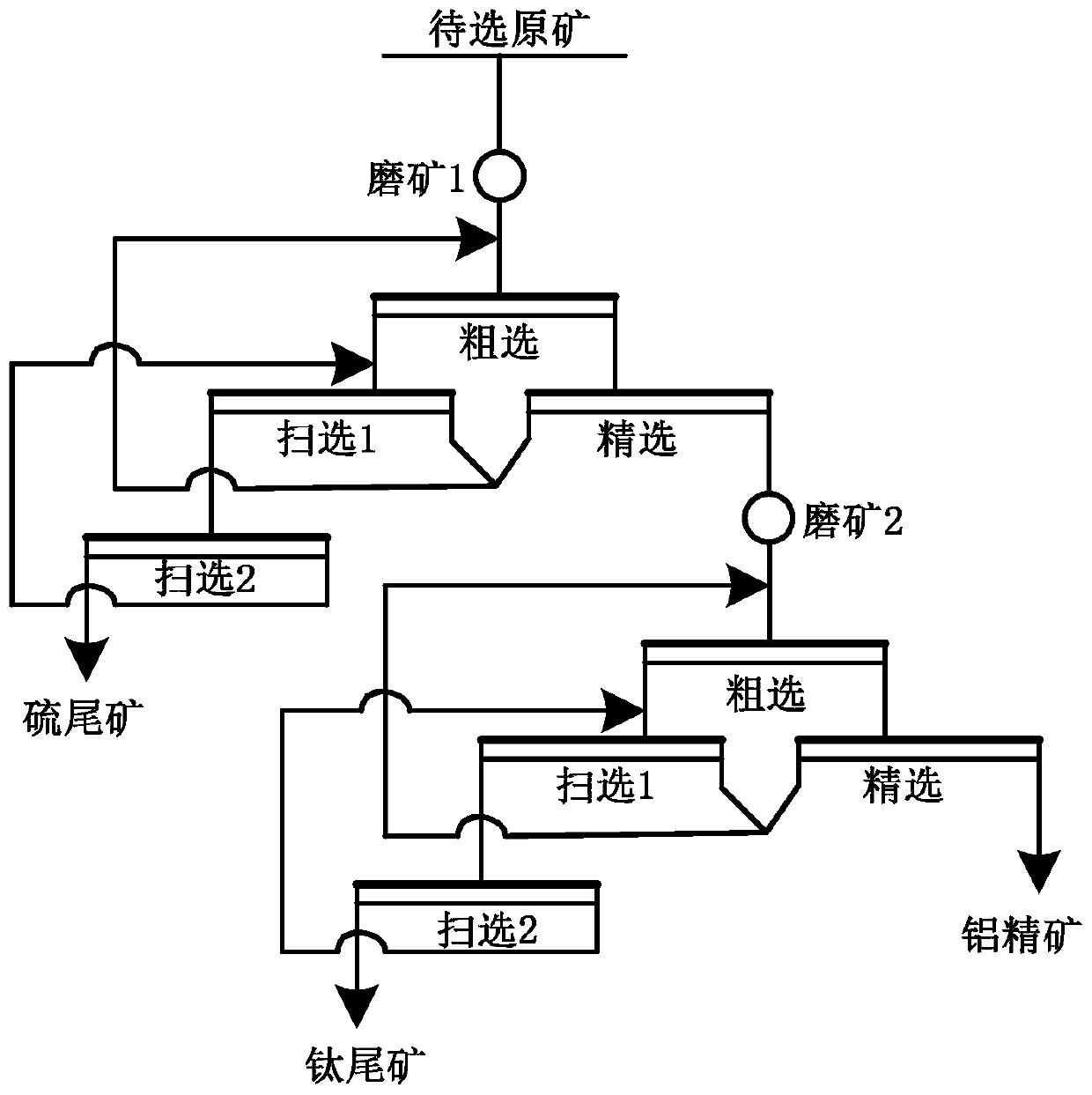

[0034] A method for removing titanium minerals in high-sulfur bauxite, comprising the following steps:

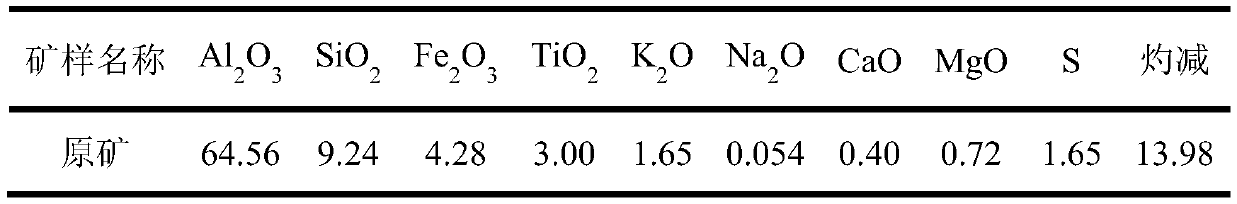

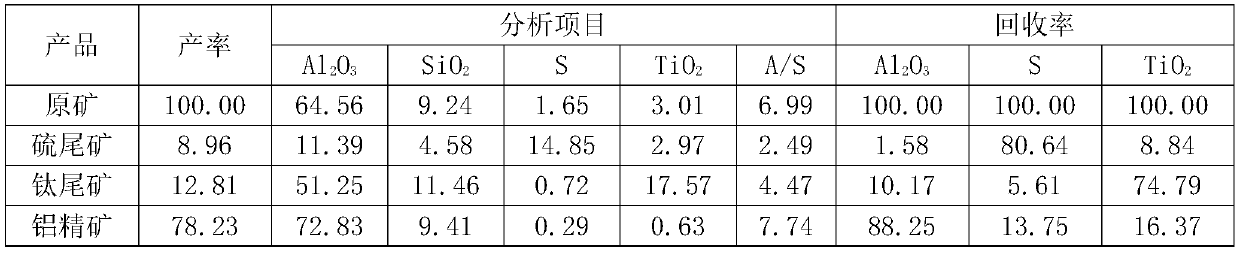

[0035] Taking the high-sulfur bauxite in a certain place in Guizhou as the test sample, the chemical multi-element analysis in the raw ore is shown in Table 1.

[0036] Table 1 Multi-element analysis of high-sulfur bauxite ore in Guizhou (%)

[0037]

[0038] According to the study of process mineralogy, the mineral composition of the ore samples is more, the main useful minerals are diaspore and a small amount of gibbsite, and the gangue minerals are mainly illite, pyrophyllite, chlorite and kaolinite and a small amount of Quartz, anatase, rutile, hematite, apatite and other minerals. The titanium minerals in the ore are mainly anatase and rutile, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com