Coal dressing composite reagent and preparing method thereof

A technology of compounding agent and preparation method, which is applied in flotation, solid separation and other directions, can solve the problems of general flotation effect, poor dispersibility, large agent consumption, etc., and achieves improved flotation effect, good stability and good economic benefits. and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

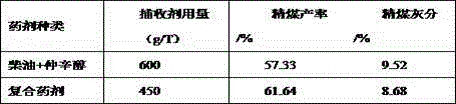

Embodiment 1

[0014] Embodiment 1, preparation coal preparation composite agent

[0015] Put 65 parts of aromatic hydrocarbon raffinate (refer to parts by mass, the same below), 15 parts of butanol raffinate and 5 parts of No. 0 light diesel oil into a stirred reactor and mix them, and start stirring for 30 minutes to form a mixed oil; at 100rmp Under the condition of stirring, add the mixed solution of 1 part of emulsifier and 14 parts of water to the obtained mixed oil, and continue to stir until the solution is brown.

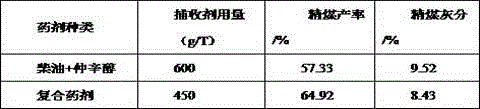

Embodiment 2

[0021] Embodiment 2, preparation coal preparation composite agent

[0022] Put 65 parts of aromatic hydrocarbon raffinate (refer to parts by mass, the same below), 15 parts of butanol raffinate and 5 parts of No. 0 light diesel oil into a stirred reactor and mix them, and start stirring for 30 minutes to form a mixed oil; at 100rmp Under the condition of stirring, add the mixed solution of 3 parts of emulsifier and 12 parts of water to the obtained mixed oil liquid, and continue to stir until the solution is brown.

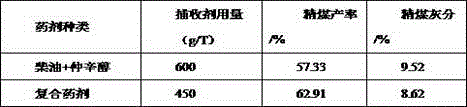

Embodiment 3

[0028] Embodiment 3, preparation coal preparation composite agent

[0029] Put 65 parts of aromatic hydrocarbon raffinate (refer to parts by mass, the same below), 15 parts of butanol raffinate and 5 parts of No. 0 light diesel oil into a stirred reactor and mix them, and start stirring for 30 minutes to form a mixed oil; at 100rmp Under the condition of stirring, add the mixed solution of 5 parts of emulsifier and 10 parts of water to the obtained mixed oil liquid, and continue to stir until the solution is brown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com