Collophanite ore beneficiation method

A mineral processing method, collophosite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high production cost, poor mineral processing effect, complicated process, etc., and achieve saving of usage, flotation The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

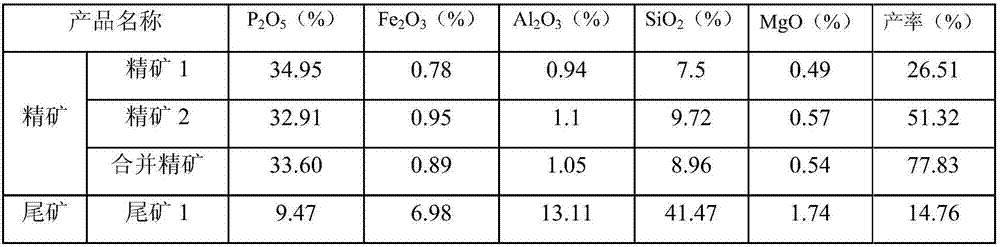

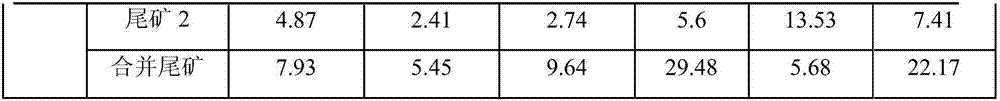

[0044] Embodiment 1 adopts the method of the present invention to flotation collophosite

[0045] The colloidite used in Example 1 is selected from the comprehensive ore sample 1 of siliceous-calcium phosphate rock in a mining area in Fuquan, Guizhou, and its main chemical composition is shown in Table 1 below:

[0046] Table 1 Collophosite composition list

[0047] Indicator name

P 2 o 5

Fe 2 o 3

al 2 o 3

SiO 2

MgO

content(%)

27.93

1.89

2.95

13.51

1.68

[0048] Adopt the inventive method to carry out beneficiation, concrete operating process is as follows:

[0049] Grinding collophosin to a fineness of less than 74 μm accounts for 35%, sieving and classifying with a 250 μm sieve and a 74 μm sieve, and performing flotation at a particle size of -74 μm to obtain concentrate 2, and a particle size of -250 μm+74 μm is concentrate 1. Concentrate 1 and concentrate 2 are combined into a qualified concentrate, an...

Embodiment 2

[0057] Embodiment 2 adopts the method of the present invention to flotation collophosite

[0058] The main chemical composition of the comprehensive sample 2 of silicon-calcium phosphate rock in a mining area in Weng'an, Guizhou is shown in Table 3 below.

[0059] Table 3 Collophosite composition list

[0060] Indicator name

P 2 o 5

Fe 2 o 3

Al 2 o 3

SiO 2

MgO

content(%)

25.88

1.64

3.57

19.72

1.98

[0061] The process is as follows: Grinding to a fineness of -74μm accounts for 38%, using 250μm sieves and 74μm sieves for sieving and classification, and -74μm particle size for flotation to obtain concentrate 2, -250μm+74μm particle size is concentrate 1, concentrate The ore 1 and the concentrate 2 are combined into a qualified concentrate, and the +250μm particle size is returned to the grinding for re-grinding.

[0062] Agents and dosages used in fine-grained flotation: tall oil soap 1.2-2.5kg / t. raw ore, s...

Embodiment 3

[0068] Embodiment 3 adopts the method of the present invention to flotation collophosite

[0069] The main chemical composition of the comprehensive sample 3 of silicon-calcium phosphate rock in a mining area in Weng'an, Guizhou is shown in Table 5 below:

[0070] Table 5 Colloidal composition list

[0071] Indicator name

P 2 o 5

Fe 2 o 3

Al 2 o 3

SiO 2

MgO

content(%)

23.67

1.38

3.23

25.72

1.74

[0072] The process is as follows: Grinding to a fineness of -74μm accounts for 42%, using 250μm sieves and 74μm sieves for sieving and classification, and -74μm particle size for flotation to obtain concentrate 2, -250μm+74μm particle size is concentrate 1, concentrate The ore 1 and the concentrate 2 are combined into a qualified concentrate, and the +250μm particle size is returned to the grinding for re-grinding.

[0073] Agents and dosages used in fine-grained flotation: tall oil soap 1.2-2.5kg / t. raw ore, sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com