Beneficiation method for comprehensively recycling strontium mineral from rare earth tailings

A mineral processing method and tailings technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of large land occupation, environmental and safety hazards, waste of resources, etc., and achieve the effect of reducing the amount of tailings produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

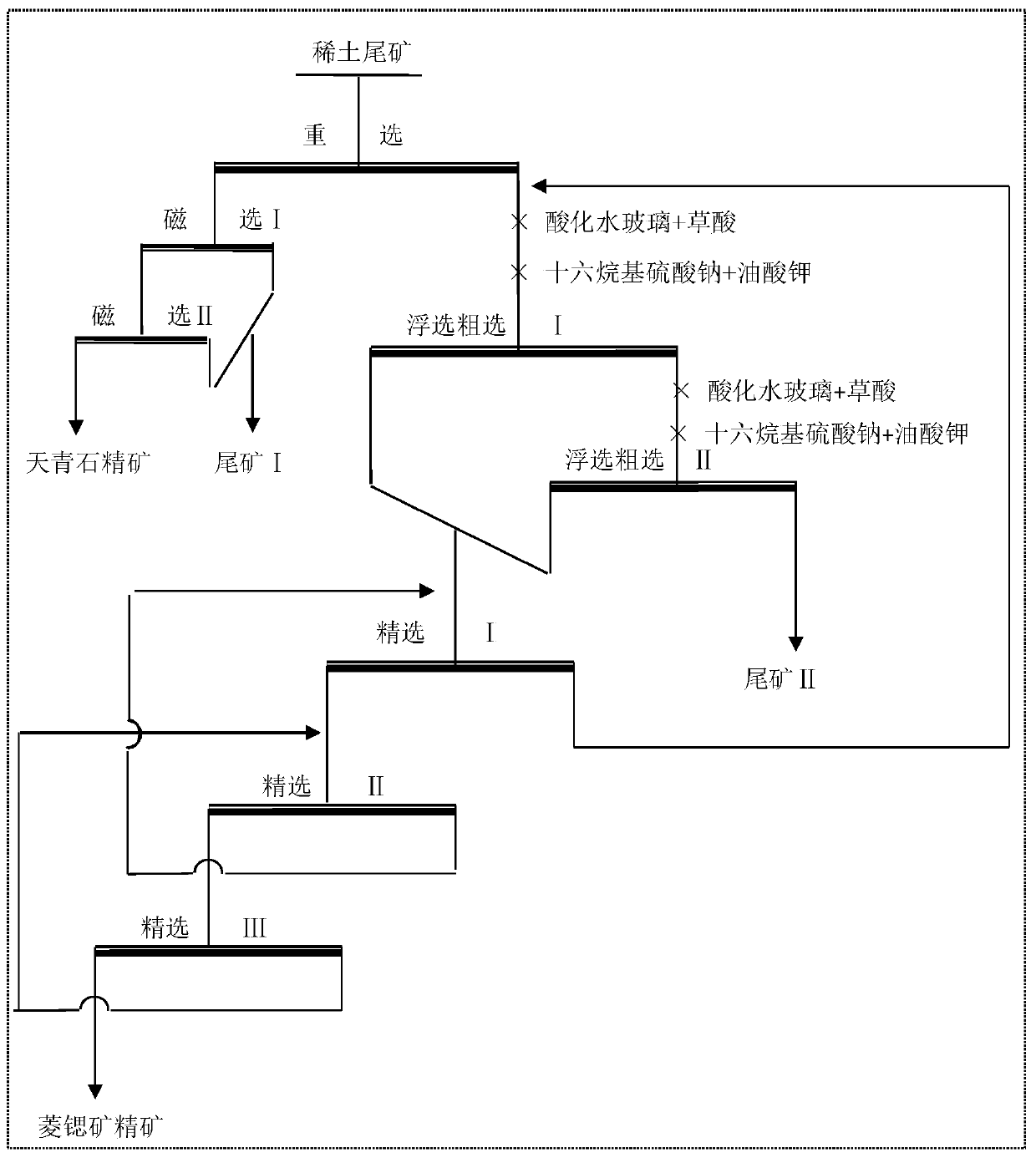

Image

Examples

Embodiment 1

[0034] A mineral processing method for comprehensively recovering strontium minerals from rare earth tailings, the steps are as follows:

[0035] 1) Take the rare earth beneficiation tailings, add water and adjust the slurry until the ore accounts for 25% of the mass percentage of the slurry. The test results show that the raw ore mainly contains SrO16.18wt%, Fe 2 o 3 3.17wt%, REO 0.85wt%, K 2 O 4.18wt%, Na 2 O 1.40wt%, Al 2 o 3 9.90wt%, SiO 2 28.32wt%, CaF 2 15.16wt%, BaO 1.25%, etc.

[0036]2) carry out two-stage gravity separation to the ore pulp of step 1), obtain gravity separation concentrate and gravity separation tailings;

[0037] 3) carry out strong magnetic separation operation to the gravity separation concentrate obtained in step 2), the magnetic separation intensity is 1.0 Tesla, obtain magnetic minerals (tailings I) and non-magnetic minerals, and the non-magnetic minerals are celestite concentrates;

Embodiment 2

[0045] A mineral processing method for comprehensively recovering strontium minerals from rare earth tailings, the steps are as follows:

[0046] 1) Take the rare earth beneficiation tailings, add water and adjust the slurry until the ore accounts for 30% of the mass percentage of the slurry. The test results show that the ore mainly contains SrO 18.50wt%, Fe 2 o 3 4.86wt%, REO 0.80wt%, K 2 O 4.20wt%, Na 2 O 1.51wt%, Al 2 o 3 9.72wt%, SiO 2 31.05wt%, CaF 2 12.28wt%, BaO 1.76%, etc.

[0047] 2) carry out two-stage gravity separation to the ore pulp of step 1), obtain gravity separation concentrate and gravity separation tailings;

[0048] 3) Carry out strong magnetic separation operation to the gravity separation concentrate obtained in step 2), the magnetic separation intensity is 1.5 tesla, obtain magnetic mineral (tailings I) and nonmagnetic mineral, nonmagnetic mineral is lapis lazuli concentrate;

[0049] 4) Add 7.5% by mass of sodium silicate solution to the grav...

Embodiment 3

[0056] A mineral processing method for comprehensively recovering strontium minerals from rare earth tailings, the steps are as follows:

[0057] 1) Take the rare earth beneficiation tailings, add water and adjust the slurry until the ore accounts for 30% of the mass percentage of the slurry. The test results show that the raw ore mainly contains 20.15wt% SrO, Fe 2 o 3 4.06wt%, REO 0.75wt%, K 2 O 3.58wt%, Na 2 O 1.03wt%, Al 2 o 3 8.13wt%, SiO 2 31.52wt%, CaF 2 11.16wt%, BaO 1.75%, etc.

[0058] 2) carry out two-stage gravity separation to the ore pulp of step 1), obtain gravity separation concentrate and gravity separation tailings;

[0059] 3) Carry out strong magnetic separation operation to the gravity separation concentrate obtained in step 2), the magnetic separation intensity is 1.2 tesla, obtain magnetic minerals (tailings I) and nonmagnetic minerals, and the nonmagnetic minerals are celestite concentrates;

[0060] 4) To the gravity separation tailings describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com