Rotary jet mixing low-energy consumption flotation equipment driven by utilizing ore pulp

A low energy consumption, jet flow technology, applied in flotation, solid separation, etc., can solve the problems of particle shedding, high energy consumption, and affecting flotation effect, and achieve the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

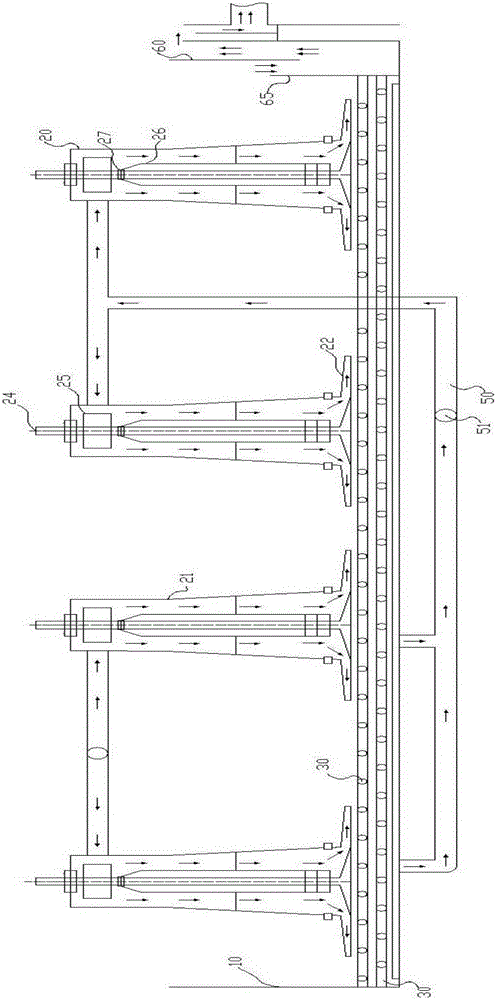

[0042] For ease of understanding, combined here Figure 1-9 , the specific embodiments of the present invention are further described as follows:

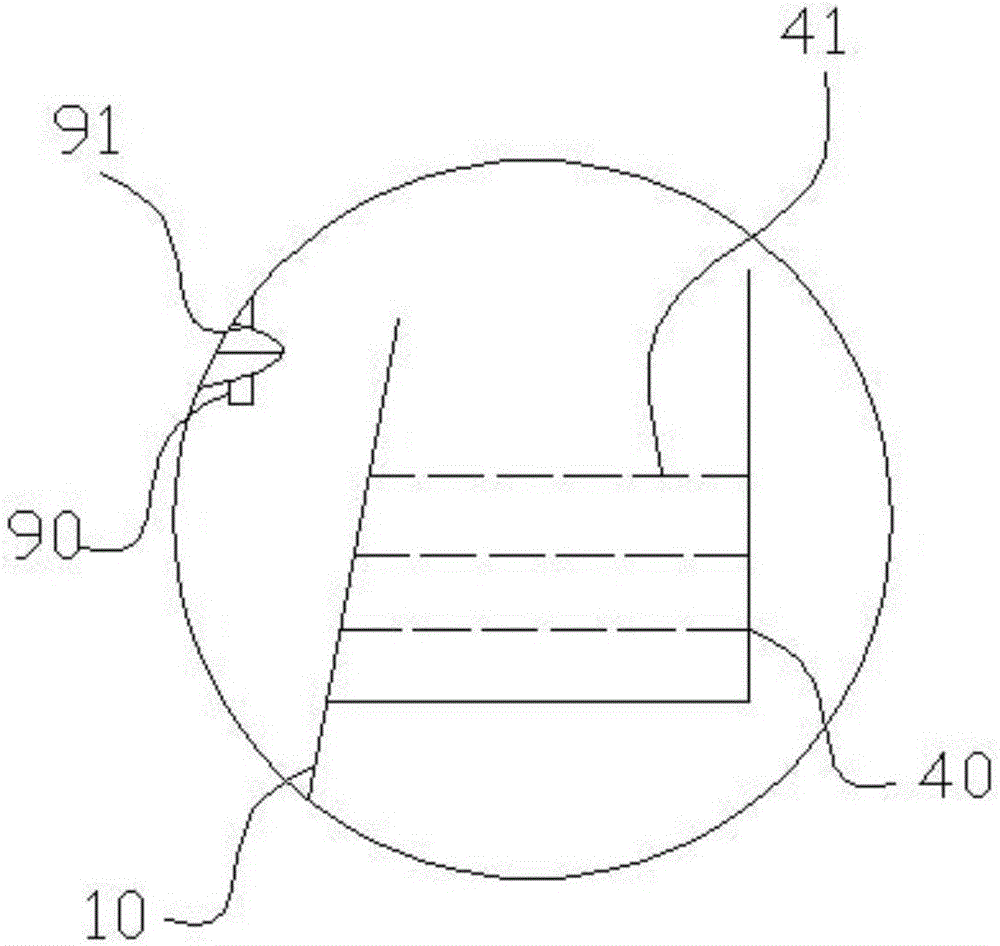

[0043] The specific components of the present invention are divided into several modules, including: feeding buffer tank 80, annular nozzle jet device 70, flotation tank 10, jet-driven agitator 20, microbubble generating bed 30, concentrate collection tank 40, Circulating foam scraping group 90, clean water spray assembly 100 and tailings box. Describe them one by one below:

[0044] 1. Flotation feeding buffer barrel

[0045] Its structure is as figure 1 As shown, the overall structure is in a cylindrical barrel, and the slurry inside is transported to the first group of mixing units by the feeding pump 80a through the feeding main pipeline, and the two jet-driven agitators 20 of the first group of mixing units are driven to work.

[0046] 2. Ring nozzle jet device

[0047] The ore slurry in the flotation feeding buffer tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com