Processing method for correcting low steepness optical mirror surface error

A technology of optical mirror surface and processing method, which is applied in the field of correction of optical mirror surface error, and can solve problems such as increasing processing cost, increasing dwell time, and inaccurate acquisition of removal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment is carried out on the ion beam polishing equipment (KDIFS-500 type can be selected), and the ion beam modification process parameters are set as follows: the working gas is argon, and the working vacuum is 0.8×10 -2 Pa, ion energy 1100eV, beam current 25mA. The polished component to be processed is a CVD SiC glass-ceramic plane with a diameter of 90 mm.

[0072] Carry out ion beam polishing to above-mentioned glass-ceramic plane by following method step:

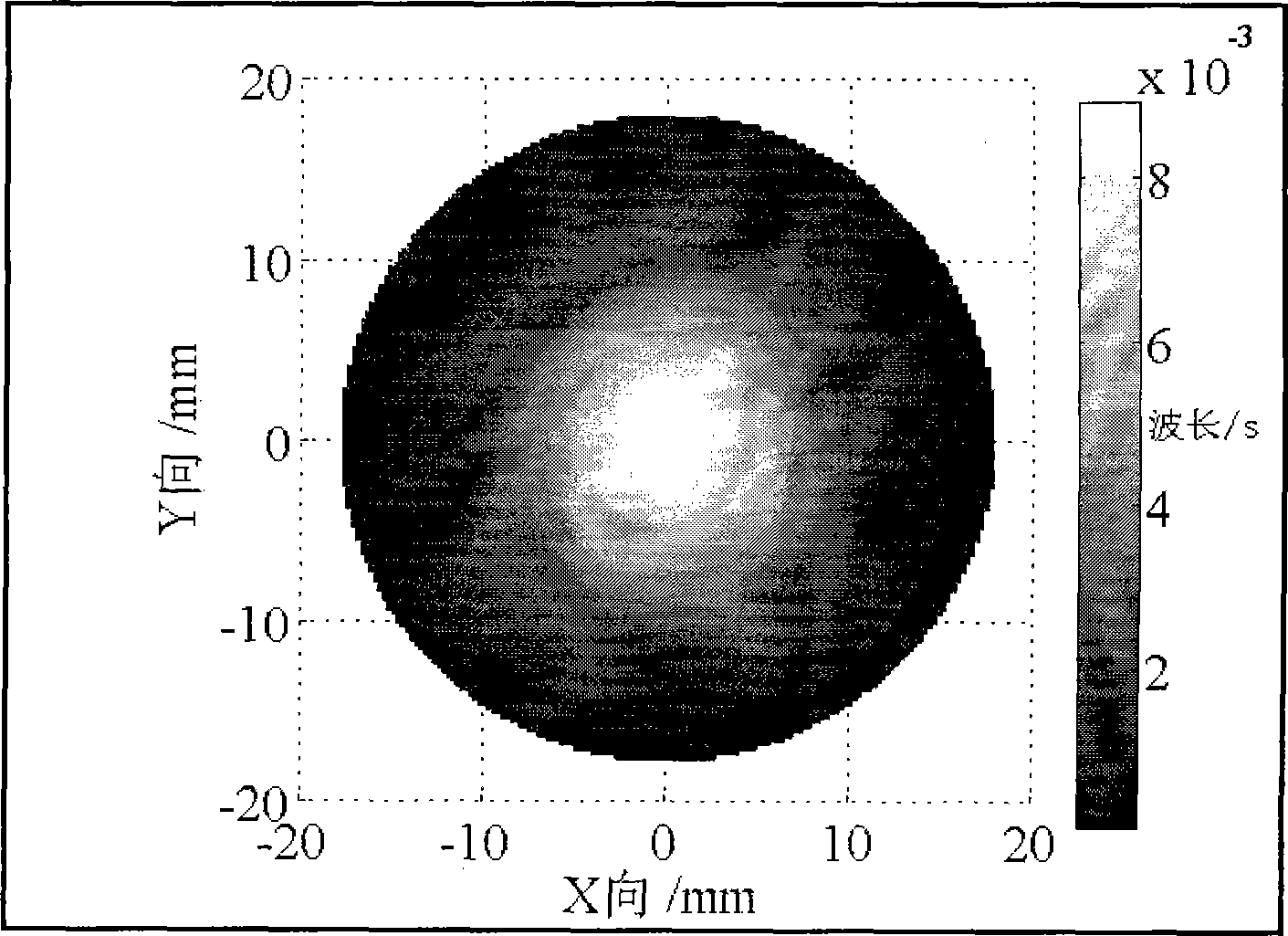

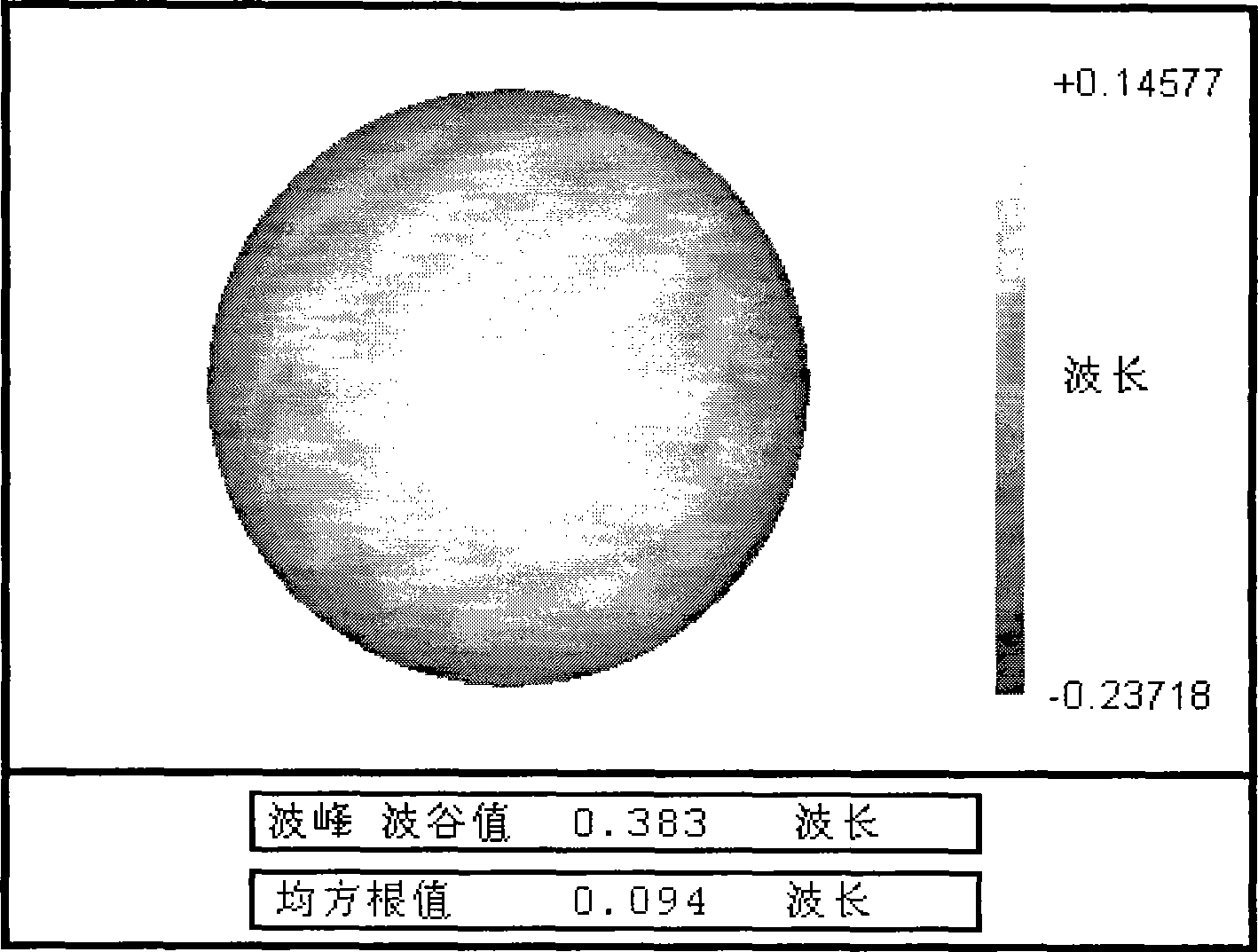

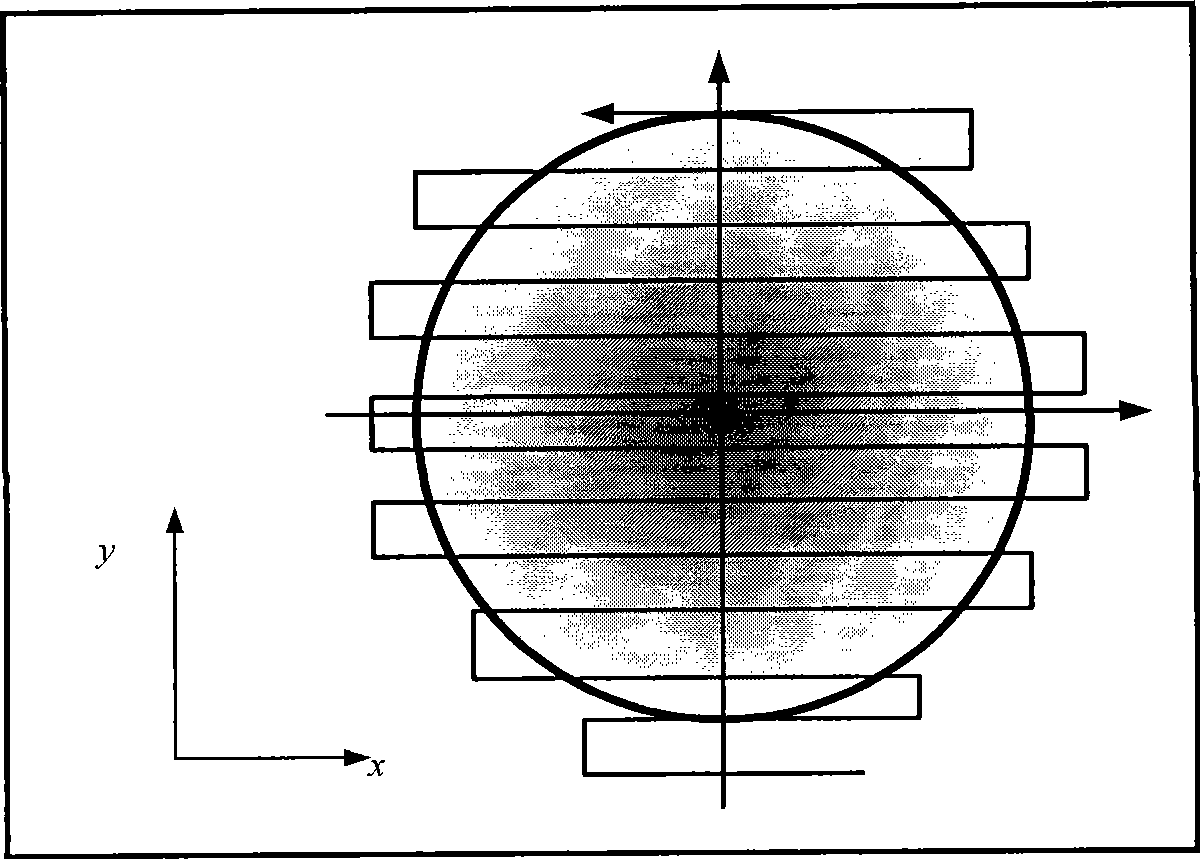

[0073] 1. Determine the removal function: apply the above-mentioned ion beam modification process to carry out the removal function test, and the obtained removal function is denoted as R(x, y), and its distribution is as follows figure 1 As shown, the radius R of the removal function t =18mm; the removal function is discretized into a 37×37 square matrix at an interval of S=1mm, and the square matrix of the removal function obtained by the discretization is denoted as R, and the efficiency paramete...

Embodiment 2

[0086] This embodiment is carried out on the ion beam polishing equipment (KDIFS-500 type can be selected), and the ion beam modification process parameters are set as follows: the working gas is argon, and the working vacuum is 0.8×10 -2Pa, ion energy 1100eV, beam current 25mA. The polished component to be processed is an ordinary glass-ceramic spherical surface with a diameter of 196 mm.

[0087] The ion beam polishing is carried out to the described glass-ceramics by the following method steps:

[0088] 1. Determine the removal function: apply the above-mentioned ion beam modification process to carry out the removal function test, and the obtained removal function is denoted as R(x, y), and its distribution is as follows figure 1 As shown, the radius R of the removal function t =18mm; the removal function is discretized into a 37×37 square matrix with an interval of S=1mm, and the square matrix of the removal function obtained by the discretization is denoted as R, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com