Method and apparatus for preparing titanium dioxide by oxidation reactor

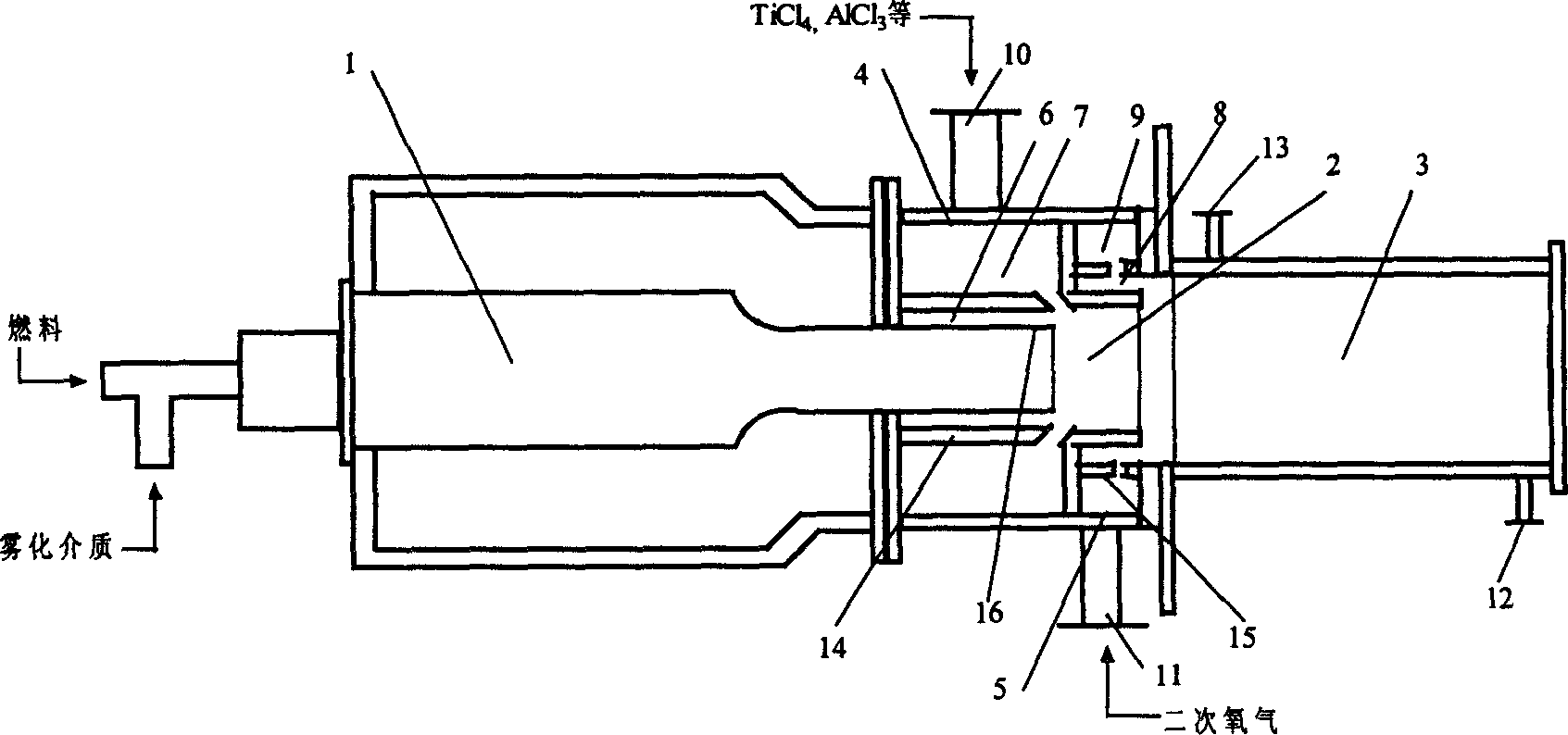

An oxidation reactor, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, fibrous fillers, etc., can solve the problem of unreasonable and effective scar prevention and scar removal measures, and the material cannot withstand high temperature oxidation corrosion and erosion , unreasonable structure design of the oxidation furnace, etc., to avoid macroscopic reverse flow, strengthen the effect of gas film protection, and achieve the effect of intense momentum exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preventing Scarring

[0028] First, use a special preheater to heat the oxygen to about 1000°C. The design principle of the preheater is to increase the temperature of the oxygen entering the oxidation reactor as much as possible. Then use the combustion of toluene to heat the oxygen to the reaction temperature of about 1800°C; the hot TiCl 4 After the gas comes out of the preheater, it enters the AlCl 3 generator, the AlCl 3 It is the product of the reaction between aluminum powder and chlorine gas entering from the upper part of the generator, and the reaction product AlCl 3 Exothermic, the TiCl 4 and AlCl 3 The mixing temperature rises to 550°C, and the mixed fluid enters the TiCl 4 oxidation reactor.

[0029] Using secondary oxygen in TiCl 4 After the feeding ring, the high-speed tangentially enters the reactor, and the rectified high-speed secondary oxygen forms an air curtain cooling layer on the inner wall of the mixing zone of the reactor and t...

Embodiment 2

[0030] Example 2: Preventing Scarring

[0031] First, preheat the oxygen to 800°C, and then use the combustion of toluene to heat the oxygen to the reaction temperature of 1600°C; heat TiCl 4 After the gas comes out of the preheater, it enters the AlCl 3 Generator, TiCl 4 and AlCl 3 The mixing temperature rises to 500°C, and the mixed fluid enters the TiCl 4 oxidation reactor. Using secondary oxygen in TiCl 4 After the feeding ring, the high-speed tangentially enters the reactor, and the rectified high-speed secondary oxygen forms an air curtain cooling layer on the inner wall of the mixing zone of the reactor and the subsequent reaction zone (cylindrical cooling zone), and there is no sintering scar layer in the reactor .

Embodiment 3

[0032] Embodiment 3: titanium dioxide quality control

[0033] The average particle size of the particles depends on the number of crystal nuclei formed in the reaction. The number of crystal nuclei depends on the activity and quantity of the nucleating species at the reaction temperature. In order to control the number of crystal nuclei, on the one hand, the degree of gas mixing is controlled, and on the other hand, the reaction temperature is controlled. A high reaction temperature will form too many crystal nuclei, resulting in a thinner average particle; a low reaction temperature will form too few crystal nuclei, resulting in a coarser average particle. In this process, the jet feeding of titanium tetrachloride is very critical, because it involves the realization of oxygen and TiCl 4 Quick, even mixing. If the two reactants are not mixed uniformly, the resulting particles may be of different sizes. Even if the average particle size meets the requirements, the particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com