Process for large-scale preparation of pravastatin sodium D-type crystal

A technology of pravastatin sodium and a process is applied in the field of large-scale preparation of pravastatin sodium D-type crystals, and can solve the problems of yellowish color of pravastatin sodium D-type crystals, low crystal transformation efficiency, and unsuitability for industrial scale-up. , to achieve the effect of simple and easy process, high crystal form conversion rate and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 pravastatin sodium type D crystal

[0031] S1: Take pravastatin sodium crystals, add butanol with a water content of 5% at a liquid-solid ratio of 0.1mL / g at a temperature of 12°C, and ultrasonically mix for 8 minutes at an ultrasonic power of 750W to prepare into a mixed slurry;

[0032] S2: Put the mixed slurry described in S1 in a vacuum drying oven, raise the temperature to 65°C, and pass high-purity nitrogen gas for 12 hours while vacuuming, and keep the vacuum value at -0.40MPa;

[0033] S3: Stop feeding high-purity nitrogen, keep the temperature at 60°C, adjust the vacuum value to -1.0MPa, and dry for 12 hours to obtain the product.

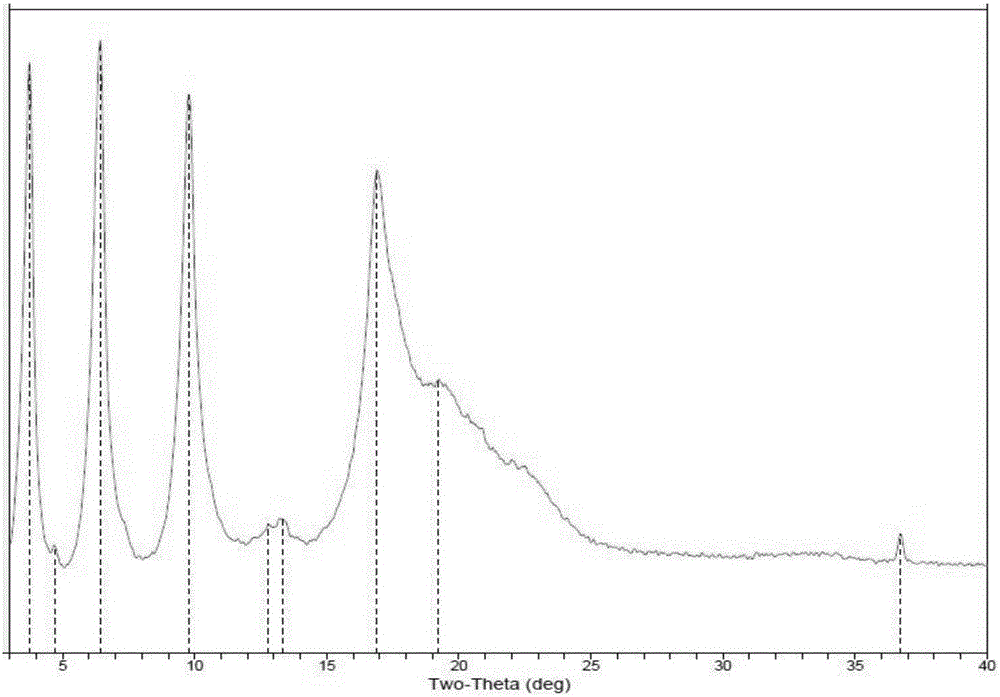

[0034] The prepared product is a white crystal, and its PXRD spectrum is as follows: figure 1 As shown, there are obvious characteristic peaks at diffraction angles 2θ°=3.8, 6.5, 9.8 and 17.0°, which are pravastatin sodium type D crystals, and it can be clearly seen from the PXRD pattern that except...

Embodiment 2

[0035] The preparation of embodiment 2 pravastatin sodium type D crystals

[0036] S1: Take pravastatin sodium crystals, and add an equal volume of acetone and propanol mixed organic solvent with a water content of 3% at a liquid-solid ratio of 0.12mL / g at a temperature of 10°C. Under the condition of 500W, ultrasonically mix for 10min to make a mixed slurry;

[0037]S2: Put the mixed slurry described in S1 in a vacuum drying oven, raise the temperature to 70°C, and pass high-purity nitrogen gas for 10 hours while vacuuming, and keep the vacuum value at -0.90MPa;

[0038] S3: Stop feeding high-purity nitrogen, keep the temperature at 50°C, adjust the vacuum value to -0.95MPa, and dry for 12h to obtain the product.

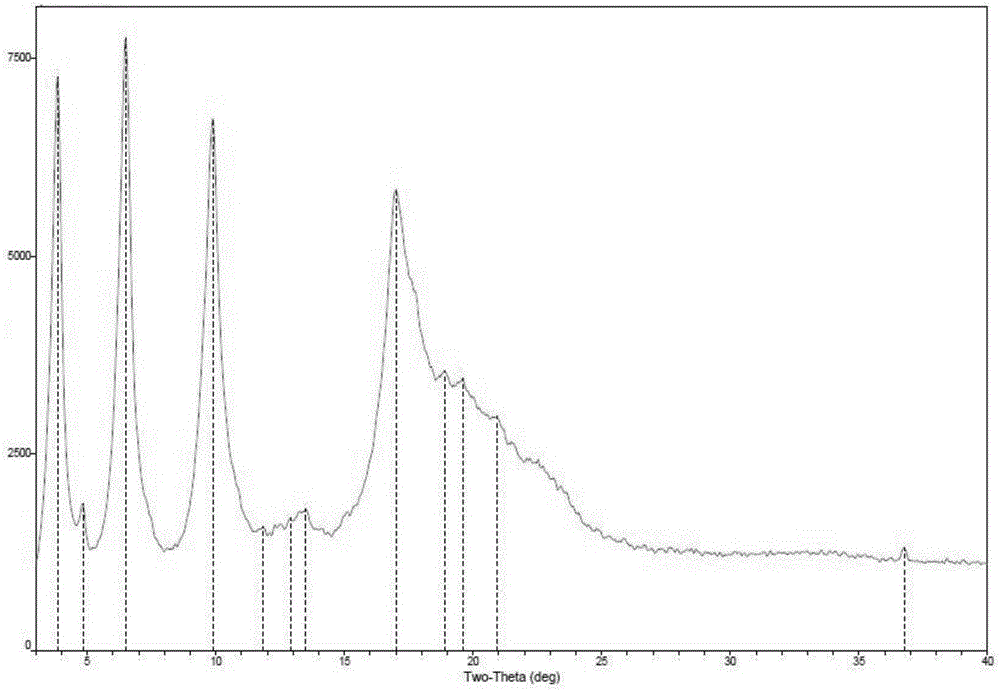

[0039] The prepared product is a white crystal, and its PXRD spectrum is as follows: figure 2 As shown, there are obvious characteristic peaks at diffraction angles 2θ°=3.7, 6.4, 9.8 and 16.9°, which is a D-type crystal of pravastatin sodium, and it can be clear...

Embodiment 3

[0040] Embodiment 3 Preparation of pravastatin sodium D-type crystal

[0041] S1: Take pravastatin sodium crystals, add propanol with a water content of 10% at a liquid-solid ratio of 0.08mL / g at a temperature of 10°C, and ultrasonically mix for 6 minutes at an ultrasonic power of 600W to prepare into a mixed slurry;

[0042] S2: Put the mixed slurry described in S1 in a vacuum drying oven, raise the temperature to 50°C, and pass high-purity nitrogen gas for 15 hours while vacuuming, and keep the vacuum value at -0.60MPa;

[0043] S3: Stop feeding high-purity nitrogen, keep the temperature at 70°C, adjust the vacuum value to -1.0MPa, and dry for 15 hours to obtain the product.

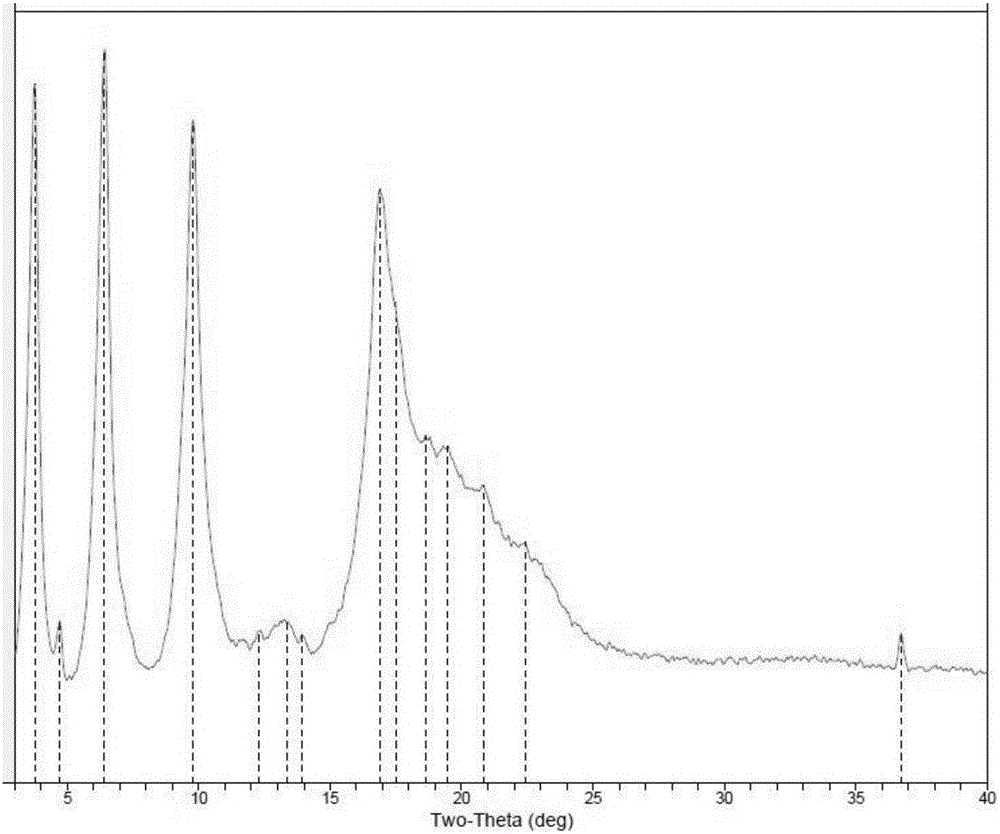

[0044] The prepared product is a white crystal, and its PXRD spectrum is as follows: image 3 As shown, there are obvious characteristic peaks at diffraction angles 2θ°=3.8, 6.4, 9.8 and 16.9°, which are pravastatin sodium type D crystals, and it can be clearly seen from the PXRD pattern that in addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com