Technique for cooling titanic chloride burner gas

A cooling process, titanium tetrachloride technology, applied in the direction of titanium halide, chemical industry, climate sustainability, etc., can solve the problems of difficult high-temperature furnace gas heat utilization, cumbersome process, and large volume, and achieve environmental protection , Protect the ecological environment, save energy and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

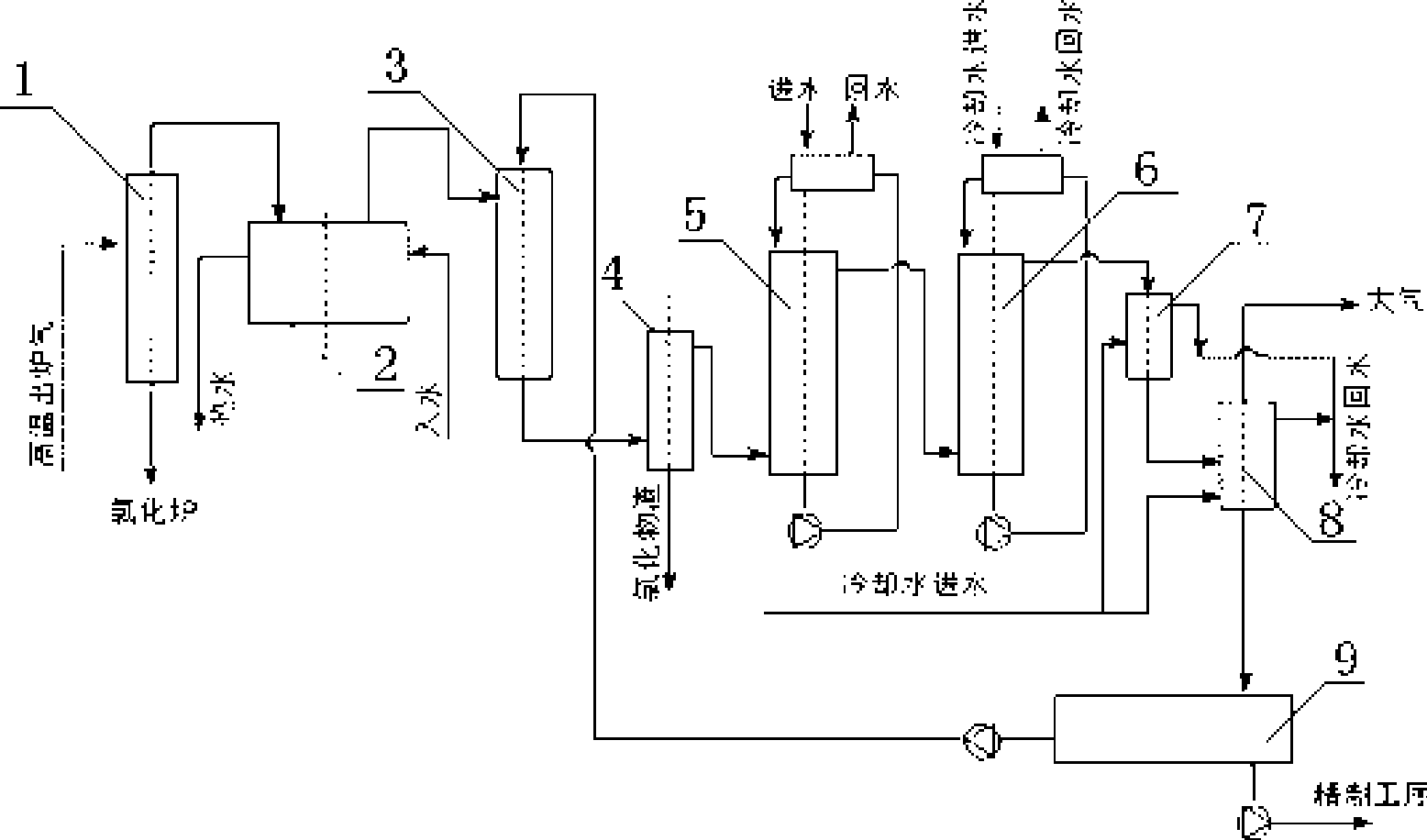

[0015] Embodiment: The temperature of titanium tetrachloride out of the furnace is about 950°C-650°C and contains dust. It first enters the cyclone dust collector 1 for dust removal, and the dust returns to the chlorination furnace to continue chlorination. High temperature gas enters 1 after exiting cyclone dust collector 1 # Cooler 2 cools the gas down to 400°C, 1 # The cooler 2 can be cooled with a water jacket to obtain hot water, so that heat energy can be recycled. The gas from the furnace enters the spray condensation tower 3 sprayed with crude titanium tetrachloride. The thick titanium tetrachloride sprayed into the spray condensation tower 3 is evaporated, so that the temperature of the discharged gas is reduced to 180-171°C. 3 Those with similar boiling points (315°C) (ZrCl 4 , CrCl 3 , NbCl 5 , AlCl 3 etc.) can become solid between 400~171℃. Then the chloride slag is removed through the bag filter 4. Cleaner gas (containing TiCl 4 、SiCl 4 , VoCl 3 , CO, C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com