Hydraulic cylinder surface shot blasting, paint spraying and drying system and shot blasting, paint spraying and drying process thereof

A technology of drying system and hydraulic cylinder, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, spraying device, etc. It can solve the problems of long drying cycle, inability to work, poor appearance quality of paint film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

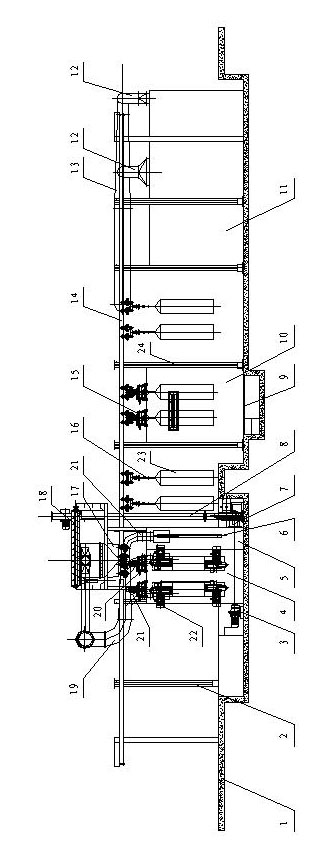

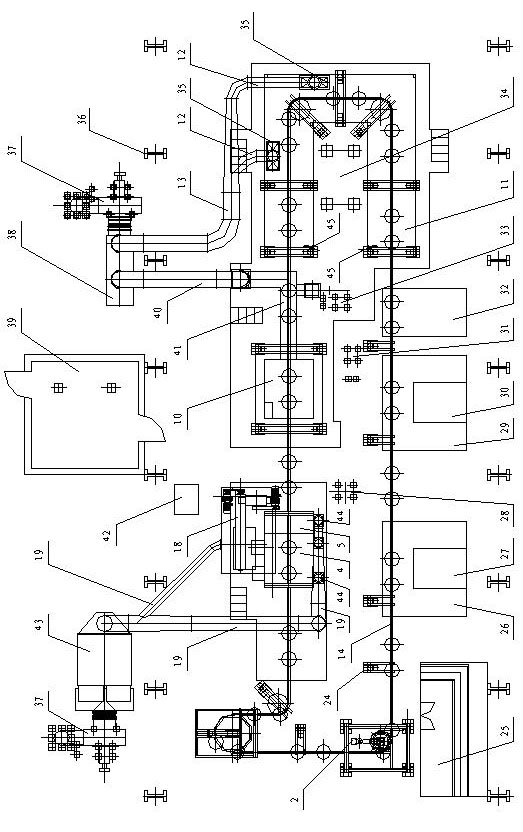

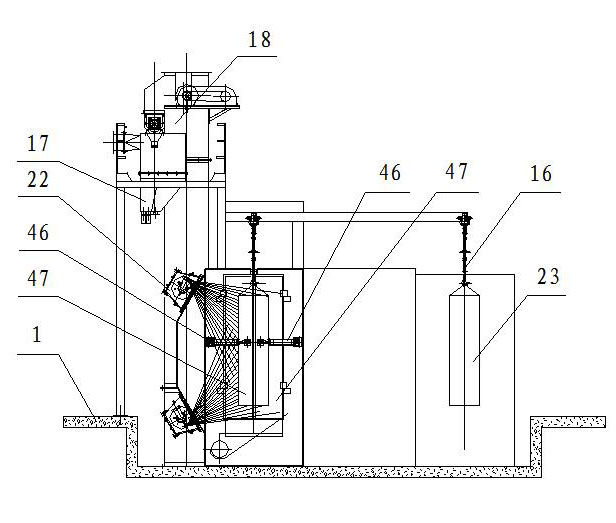

[0050] like figure 1——As shown in 5, a hydraulic cylinder surface shot blasting and painting drying system consists of a catenary conveying system, a shot blasting station, a painting station, a drying station, a maintenance station 32, a feeding station 29, an upper The material station 26, the paint mixing room 39, the air compressor 42 and the operation room 25 are characterized in that: the shot blasting paint drying system is set in the factory building, and the catenary conveying system is composed of a support 24, a catenary conveying cycle The track 14, the electric catenary hook 16 and the catenary conveyor 2 are composed of several supports 24 arranged in a ring and vertically installed on the ground in the middle of the factory building. On the top of the support 24, several electric catenary hooks 16 are suspended on the catenary conveying cycle track 14, and the catenary conveyor 2 is installed on the front support 24 on the left side of the catenary conveying cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com