Automatic cleaning device for bristle roll of combing machine and cleaning method thereof

A technology of automatic cleaning and brush rollers, which is applied to combing machines, cleaning methods and tools, cleaning methods using tools, etc., can solve the problems of hair particles, wool sheets, heavy labor intensity, laborious manual cleaning, etc., and achieve Reduce the degree of damage, improve the cleaning state, and improve the cleaning effect

Inactive Publication Date: 2008-10-15

SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD +1

View PDF3 Cites 65 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The round brush in the cleaning mechanism of the combing machine completes the cleaning work of the round comb. The quality of its cleaning status directly affects the index of the comber’s sliver grains. In order to ensure the good working condition of the round brush, we must After working continuously for 48 hours, it was removed for cleaning and reversed. Because the short hairs, hair grains, and wool pieces cleaned by the round brush during operation tend to form dead knots at the root, manual cleaning is very laborious, and the number of combing equipment Many, resulting in high labor intensity for workers, long processing time, and it is difficult to clean up. At present, there are no literature reports and related equipment for combing machine brush cleaning equipment with high degree of automation and high cleaning efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

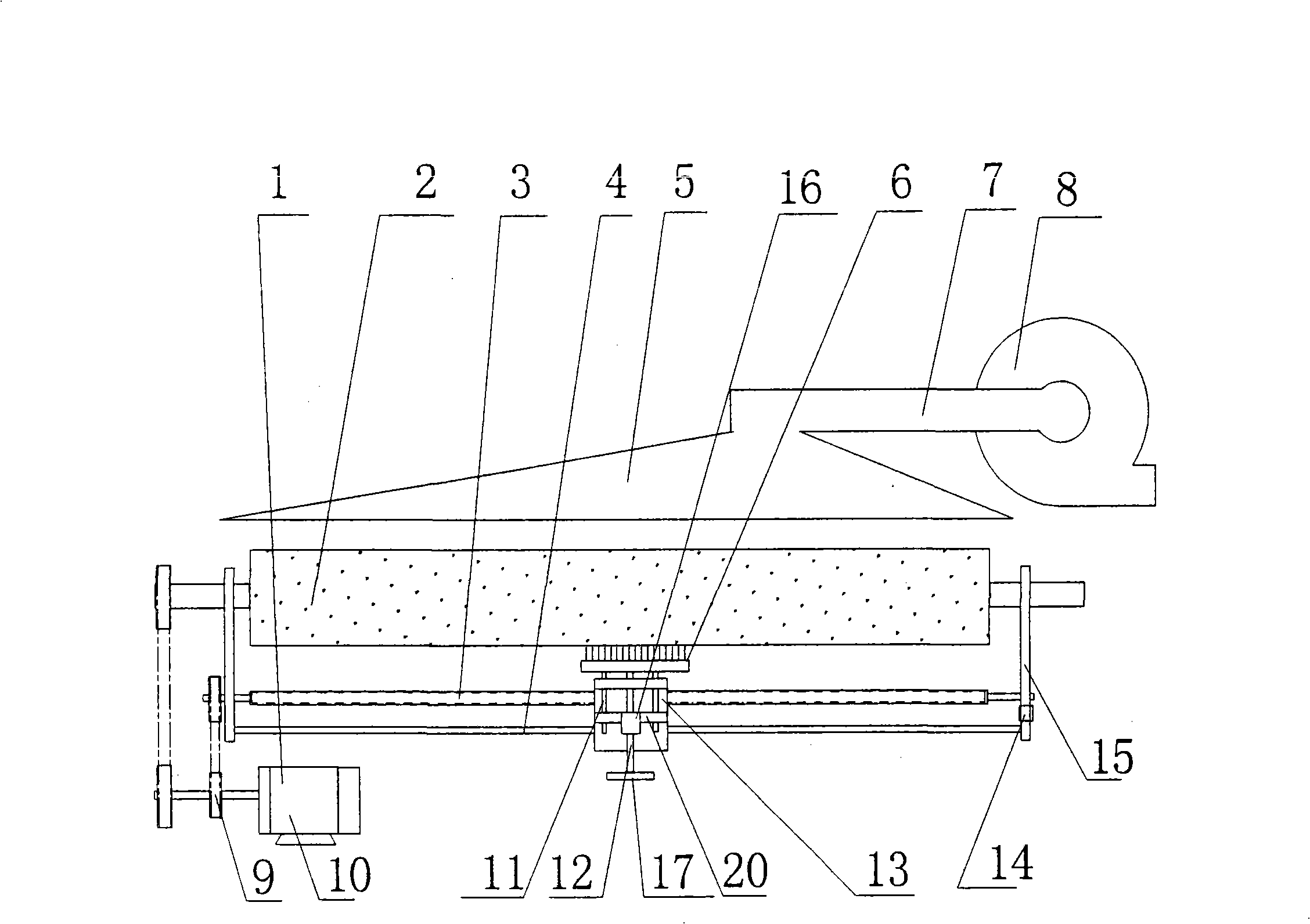

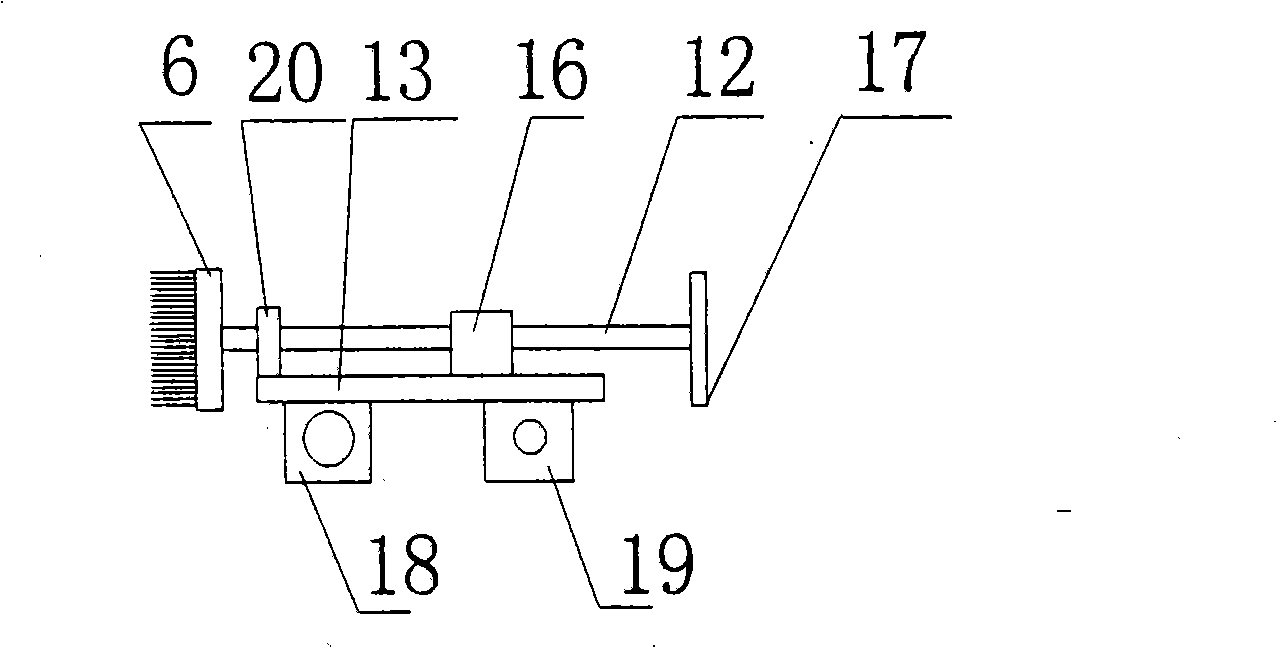

The invention provides an automatic cleaning device of a brush roller of a combing machine and a method for cleaning the same. The method comprises the following steps that: the upper side of the brush roller of the combing machine is provided with a dust hood which is connected with a draft fan through an air duct; the front part of the brush roller of the combing machine is provided with a brush roller cleaning mechanism; sundries which are attached on the brush roller of the combing machine are cleaned by contacting the brush roller cleaning mechanism with the surface of the brush roller of the combing machine. The automatic cleaning device of the brush roller of the combing machine and the method for cleaning the same are designed based on the principles of automation, cleaning and actual effect, which improve greatly work efficiency of an equipment maintainer so that the work must be done originally by two persons, but now the work can be done by one person after the brush automatic cleaner is used. Compared with the brush which is cleaned by persons, the brush which is cleaned by the brush automatic cleaner is cleaner, and the brush hair is straighter; and after the brush is operating, the state of cleaning the circular comb by the brush is improved greatly.

Description

Automatic cleaning device and cleaning method for brush roller of combing machine 1. Technical field The invention relates to an automatic improvement technology of textile machinery, in particular to an automatic cleaning device and a cleaning method for brush rollers of a combing machine. 2. Background technology The round brush in the cleaning mechanism of the combing machine completes the cleaning work of the round comb. The quality of its cleaning status directly affects the index of the comber’s sliver grains. In order to ensure the good working condition of the round brush, we must After working continuously for 48 hours, it was removed for cleaning and reversed. Because the short hairs, hair grains, and wool pieces cleaned by the round brush during operation tend to form dead knots at the root, manual cleaning is very laborious, and the number of combing equipment Many, thus causing the labor intensity of the workers, the processing time is long, and it is difficul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01G19/06B08B1/00

Inventor 丁彩玲邓云霞张养林陈振赵辉王明秋韩田革

Owner SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com