Cutting making process of silicon carbide boat for chip manufacture

A technology of silicon carbide boat and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, metal processing, electrical components, etc., can solve the problems of high processing cost, high cost, high damage rate, etc., and achieve high precision, high production efficiency, The effect of low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

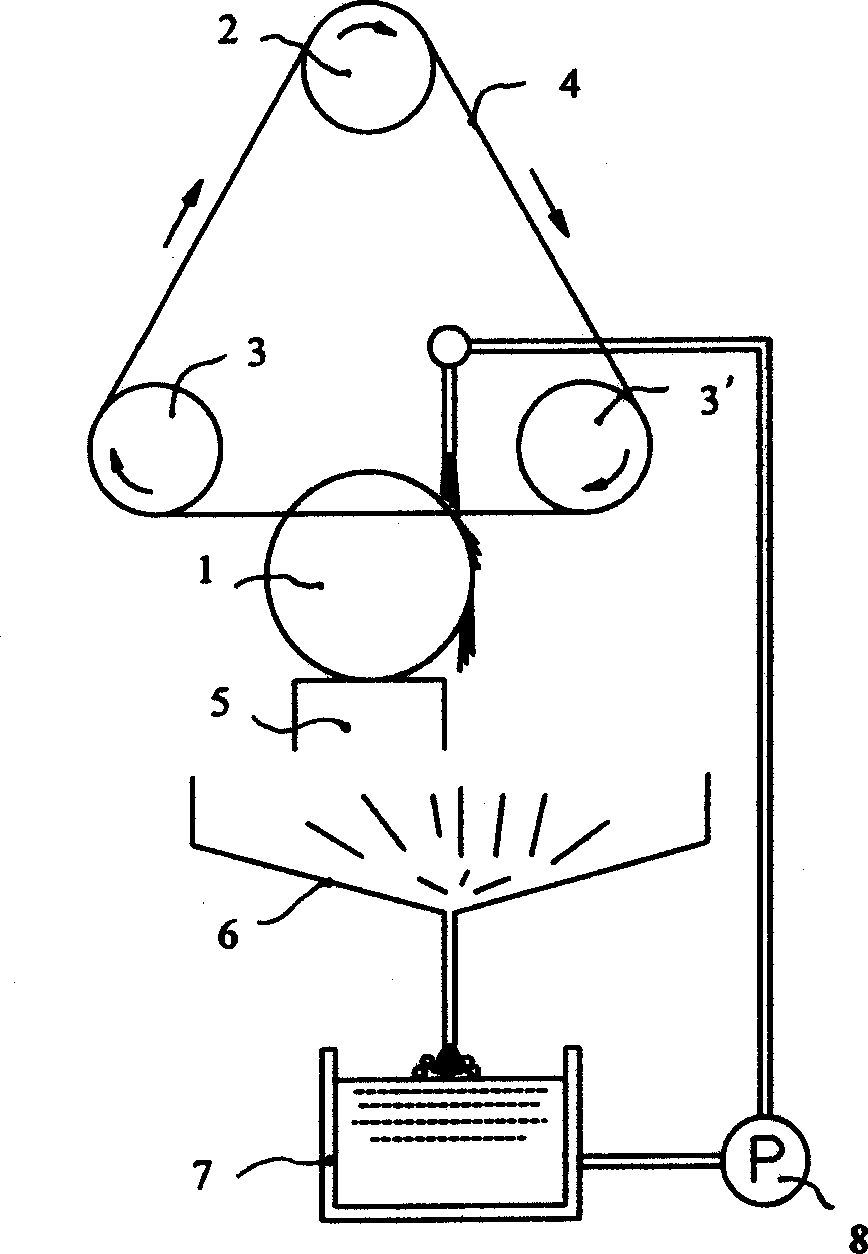

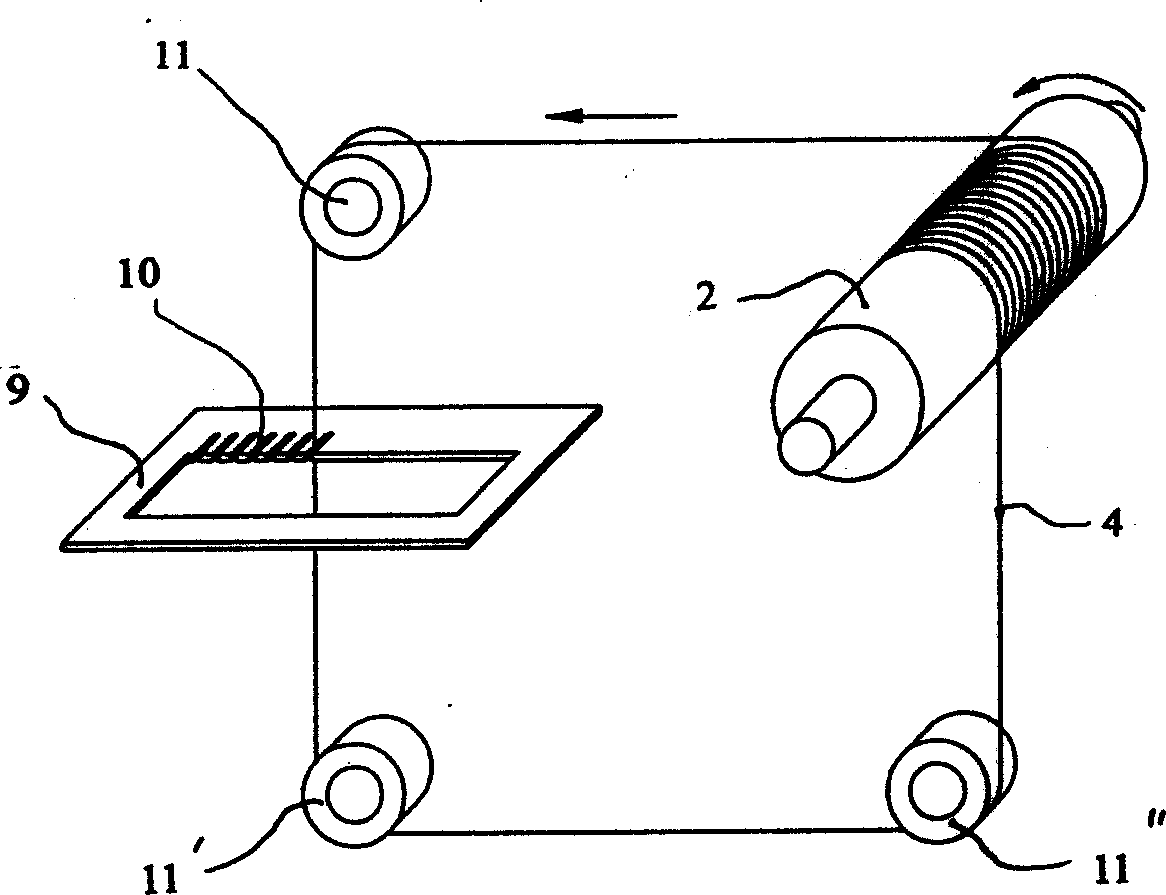

[0011] first embodiment, figure 1 Shown is the schematic diagram of the wire cutting processing equipment and technology that the present invention is used for processing and manufacturing the silicon carbide boat that semiconductor wafer is used, and workpiece 1 is clamped on the workbench by fixture, and the cutting that is made up of a roller and two guide wheels Wire drive train, that roller on the top is the winding driving roller 2, and guide wheels 3, 3' can regulate the tension of cutting line 4. The core wire of the cutting wire 4 is a tungsten-molybdenum wire, and the outer part includes corundum powder coating. The particle size of described corundum powder is 260 grains / cm 2 , the hardness of the diamond powder is 10 on the Mohs scale. The cutting line 4 is wound on the drive roller 2 (see figure 2 ), the rotational speed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com