Method for measuring high content lead in iron-containing dust and mud

A determination method and high-content technology, applied in the field of analytical chemistry, can solve problems such as lead-free analysis methods, and achieve the effects of simple operation, high precision, and short measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Will 1 # The iron-containing dust is crushed and ground to make it into a sample with a particle size of 120 mesh.

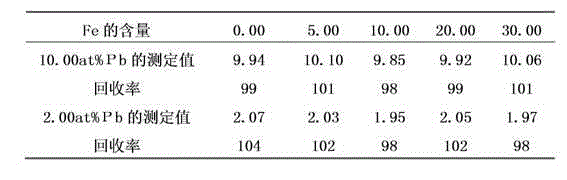

[0047] Weigh 0.1000g1 # Put the sample in a 250mL polytetrafluoroethylene beaker, wet it with water, make it dispersed, add 13mL hydrochloric acid (ρ 1.19g / mL), add 7mL nitric acid (ρ 1.42g / mL), 10mL hydrofluoric acid (ρ 1.13g / mL) ), dissolve at low temperature, after the sample dissolves, add 3mL of perchloric acid (ρ 1.68g / mL) and continue heating until perchloric acid fumes are emitted, until the remaining solution volume is nearly dry, cool slightly, add 5mL of water, add ρ 1.42g / mL 5mL of nitric acid, dissolved salts, transferred to a 250mL volumetric flask, diluted with water to the mark, shaken up, along with a reagent blank, measured by an inductively coupled plasma atomic emission spectrometer; the measurement results are shown in Table 4.

[0048] Drawing of working curve

[0049]Weigh 0.05g of high-purity iron in seven 250mL beakers, add 10m...

Embodiment 2

[0058] Will 2 # The iron-containing dust is crushed and ground to make it into a sample with a particle size of 120 mesh.

[0059] Weigh 0.1000g2 # Put the sample in a 250mL polytetrafluoroethylene beaker, wet it with water, make it dispersed, add 10mL hydrochloric acid (ρ 1.19g / mL), add 7mL nitric acid (ρ 1.42g / mL), 10mL hydrofluoric acid (ρ 1.13g / mL) ), dissolve at low temperature, after the sample dissolves, add 2mL of perchloric acid (ρ 1.68g / mL) and continue to heat until the fumes of perchloric acid are emitted until the remaining solution volume is about 1mL, cool slightly, add 5mL of water, add ρ 1.42g / mL 5mL of nitric acid, dissolve salts, transfer in the 250mL volumetric flask, dilute to scale with water, shake up, along with reagent blank, adopt inductively coupled plasma atomic emission spectrometer to measure; Calculate according to embodiment 1 calculation formula and measuring method , the results are shown in Table 4.

[0060] Drawing of working curve

[00...

Embodiment 3

[0063] Will 3 # The iron-containing dust is crushed and ground to make it into a sample with a particle size of 120 mesh.

[0064] Weigh 0.1000g3 # Put the sample in a 250mL polytetrafluoroethylene beaker, wet it with water, make it dispersed, add 10mL hydrochloric acid (ρ 1.19g / mL), add 10mL nitric acid (ρ 1.42g / mL), 10mL hydrofluoric acid (ρ 1.13g / mL) ), dissolve at low temperature, after the sample dissolves, add 2mL of perchloric acid (ρ 1.68g / mL) and continue to heat until perchloric acid fumes are emitted until the remaining solution volume is nearly dry, then cool slightly, add 5mL of water, and add ρ 1.42g / mL 5mL of nitric acid, dissolve salts, transfer in the 250mL volumetric flask, dilute to scale with water, shake up, along with reagent blank, adopt inductively coupled plasma atomic emission spectrometer to measure; Calculate according to embodiment 1 calculation formula and measuring method , the results are shown in Table 4.

[0065] Drawing of working curve

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com