Nanometer filler cooperatively filling epoxy resin composite coating as well as preparation method and application thereof

A technology of epoxy resin and nano filler, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of poor wear resistance, achieve the effects of improved wear resistance, firm interface bonding, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

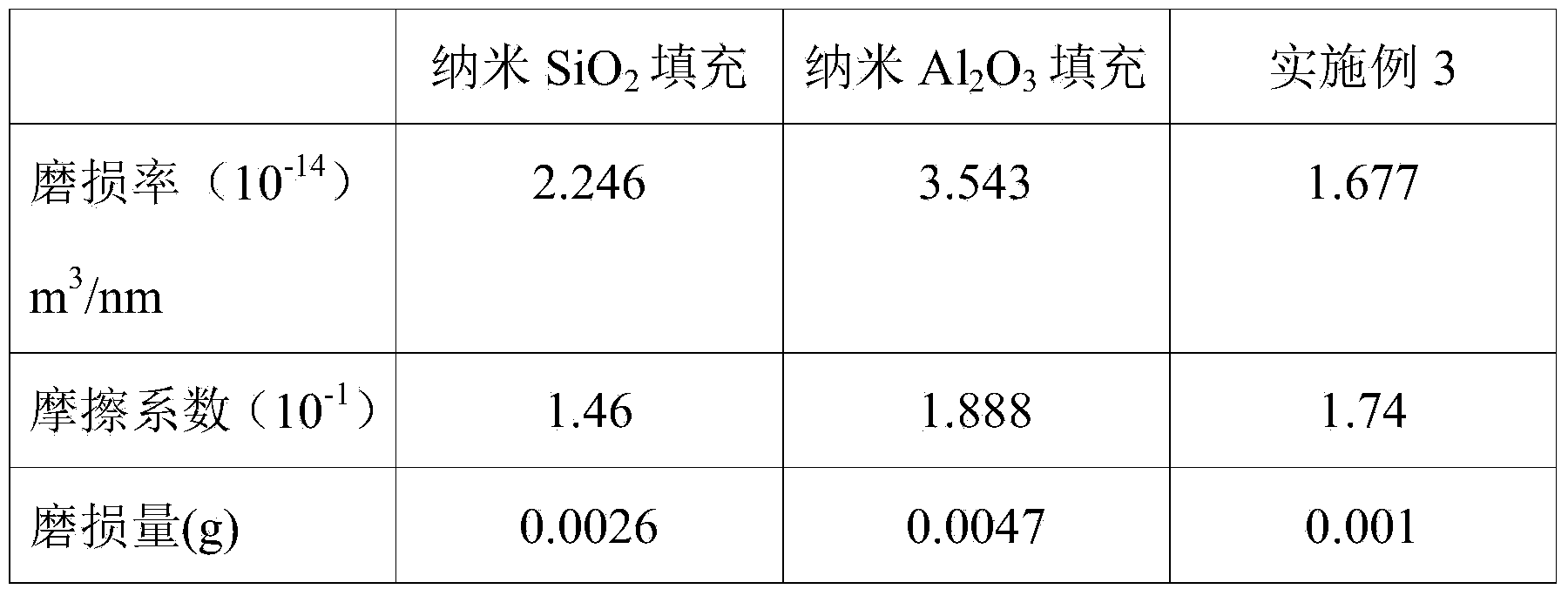

Examples

preparation example Construction

[0031] The preparation method of above-mentioned coating comprises the following steps:

[0032] Step 1: Incorporate nano-SiO 2 Mix with coupling agent KH550 and acetone at a mass ratio of 1:1:8-10, ultrasonically treat for 20-30 minutes, and dry at 75°C-85°C to obtain modified nano-SiO 2 , spare; nano-SiO 2 It is spherical, with an average particle size of 20nm and a purity of ≥99%;

[0033] Step 2: Incorporate nano-Al 2 o 3Mix with coupling agent KH550 and acetone at a mass ratio of 1:1:8-10, ultrasonically treat for 20-30 minutes, and dry at 75°C-85°C to obtain modified nano-Al 2 o 3 , spare; nano-Al 2 o 3 It is spherical, with an average particle size of 70nm and a purity of ≥99%;

[0034] Step 3: Mix epoxy resin and butanone according to the mass-volume ratio of 1g: 2 ~ 3mL to form an epoxy / butanone solution to obtain solution A; mix polyamide resin and toluene according to the mass-volume ratio of 1g: 2 ~ 3mL was made into a polyamide / toluene solution to obtain ...

Embodiment 1

[0053] Step 1: Incorporate nano-SiO 2 Mix with coupling agent KH550 and acetone at a mass ratio of 1:1:8, ultrasonically treat for 20 minutes, and dry at 75°C to obtain modified nano-SiO 2 , spare; nano-SiO 2 It is spherical, with an average particle size of 20nm and a purity of ≥99%;

[0054] Step 2: Incorporate nano-Al 2 o 3 Mix with coupling agent KH550 and acetone at a mass ratio of 1:1:8, ultrasonically treat for 20 minutes, and dry at 75°C to obtain modified nano-Al 2 o 3 , spare; nano-Al 2 o 3 It is spherical, with an average particle size of 70nm and a purity of ≥99%;

[0055] Step 3: Mix epoxy resin E51 and methyl ethyl ketone according to the mass-volume ratio of 1g:2mL to form an epoxy / butanone solution to obtain solution A; mix polyamide resin 400 and toluene according to the mass-volume ratio of 1g:2mL Become polyamide / toluene solution, obtain solution B, standby;

[0056] Step 4: Add the modified nano-Al obtained in step 2 to the solution A obtained in s...

Embodiment 2

[0064] Step 1: Incorporate nano-SiO 2 Mix with coupling agent KH550 and acetone at a mass ratio of 1:1:9, ultrasonically treat for 25 minutes, and dry at 85°C to obtain modified nano-SiO 2 , spare; nano-SiO 2 It is spherical, with an average particle size of 20nm and a purity of ≥99%;

[0065] Step 2: Incorporate nano-Al 2 o 3 Mix with coupling agent KH550 and acetone at a mass ratio of 1:1:9, ultrasonically treat for 25 minutes, and dry at 85°C to obtain modified nano-Al 2 o 3 , spare; nano-Al 2 o 3 It is spherical, with an average particle size of 70nm and a purity of ≥99%;

[0066] Step 3: Mix epoxy resin E44 and methyl ethyl ketone according to the mass-volume ratio of 1g:3mL to form an epoxy / butanone solution to obtain solution A; mix polyamide resin 300 and toluene according to the mass-volume ratio of 1g:3mL Become polyamide / toluene solution, obtain solution B, standby;

[0067] Step 4: Add the modified nano-Al obtained in step 2 to the solution A obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com