Ceramic grid enhanced metal matrix composite perform and preparation method thereof

A technology of metal matrix composite and prefabricated body, which is applied in the field of ceramic grid reinforced metal matrix composite prefabricated body and its preparation, to achieve the effects of long wear life, improved wear resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

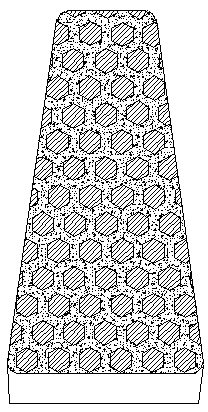

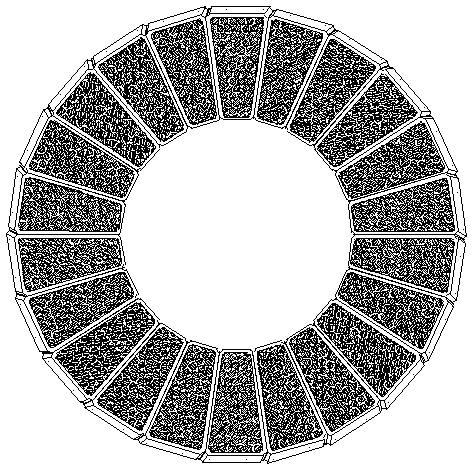

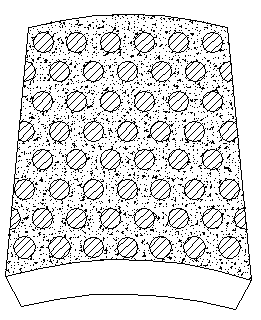

Image

Examples

Embodiment 1

[0036] (1) Mix zirconia particles with a particle size of 8-30 mesh and iron-based self-fluxing alloy powder with polyvinyl alcohol to obtain a mixture, wherein the volume ratio of ceramic particles and iron-based self-fluxing alloy powder is 1:19 , the amount of polyvinyl alcohol added is 2% of the ceramic mass;

[0037] (2) Fill the above mixture into the grid cavity, pre-press to form a ceramic grid, and then fill the grid hole with iron-based self-fluxing alloy powder after the grid is demoulded, and then use 100~ Pressing with 300 kg of force, after molding and demoulding, put the biscuit together with the bottom plate of the cavity into a drying oven at 150°C for 2 hours to dry;

[0038] (3) Put the dried biscuit together with the bottom plate of the mold cavity into a vacuum furnace for sintering at a temperature of 1150°C and a vacuum degree of 0.1 Pa for 40 minutes, and after cooling out of the furnace, a ceramic grid-reinforced metal matrix composite preform is obtai...

Embodiment 2

[0044] (1) Mix tungsten carbide particles with a particle size of 8-30 mesh and iron-based self-fluxing alloy powder with polyvinyl alcohol to obtain a mixture, wherein the volume ratio of ceramic particles and iron-based self-fluxing alloy powder is 1:4 , the amount of polyvinyl alcohol added is 1% of the ceramic mass;

[0045] (2) Fill the above mixture into the grid cavity, pre-press to form a ceramic grid, and then fill the grid hole with iron-based self-fluxing alloy powder after the grid is demoulded, and then use 100~ Pressing with 300 kg of force, after molding and demoulding, put the biscuit together with the bottom plate of the cavity into a drying oven at 150°C for 2 hours to dry;

[0046] (3) Put the dried biscuit together with the bottom plate of the mold cavity into a vacuum furnace for sintering at a temperature of 1000°C and a vacuum degree of 0.1 Pa for 30 minutes. After cooling out of the furnace, a ceramic grid-reinforced metal matrix composite preform is ob...

Embodiment 3

[0051] (1) Mix silicon carbide particles with a particle size of 8-30 mesh and nickel-based self-fluxing alloy powder with polyvinyl alcohol to obtain a mixture, wherein the volume ratio of ceramic particles and nickel-based self-fluxing alloy powder is 1:1 , the amount of polyvinyl alcohol added is 6% of the ceramic mass;

[0052] (2) Fill the above mixture into the grid cavity, and pre-press it into a ceramic grid with appropriate pressure. After the grid is demoulded, fill the grid hole with nickel-based self-fluxing alloy powder. The whole material is then made of 100 ~300 kg force pressing, after molding and demoulding, put the biscuit together with the bottom plate of the cavity into a 150°C drying oven to dry for 2 hours;

[0053] (3) Put the dried biscuit together with the bottom plate of the mold cavity into a vacuum furnace for sintering at a temperature of 1300°C and a vacuum degree of 0.1 Pa for 60 minutes, and after cooling out of the furnace, a ceramic grid-reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com