Stepwise magnetic force hoisting type reactor control rod driving mechanism

A driving mechanism and reactor technology, which is applied in the control of nuclear reactions, reactors, and greenhouse gas reduction, etc., can solve the problems of difficulty in guaranteeing parallelism, poor impact resistance, and complex structure of parallel four-bar mechanisms, so as to improve safety and reliability. The effects of improved durability, increased wear life, and reduced chance of hook tooth breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

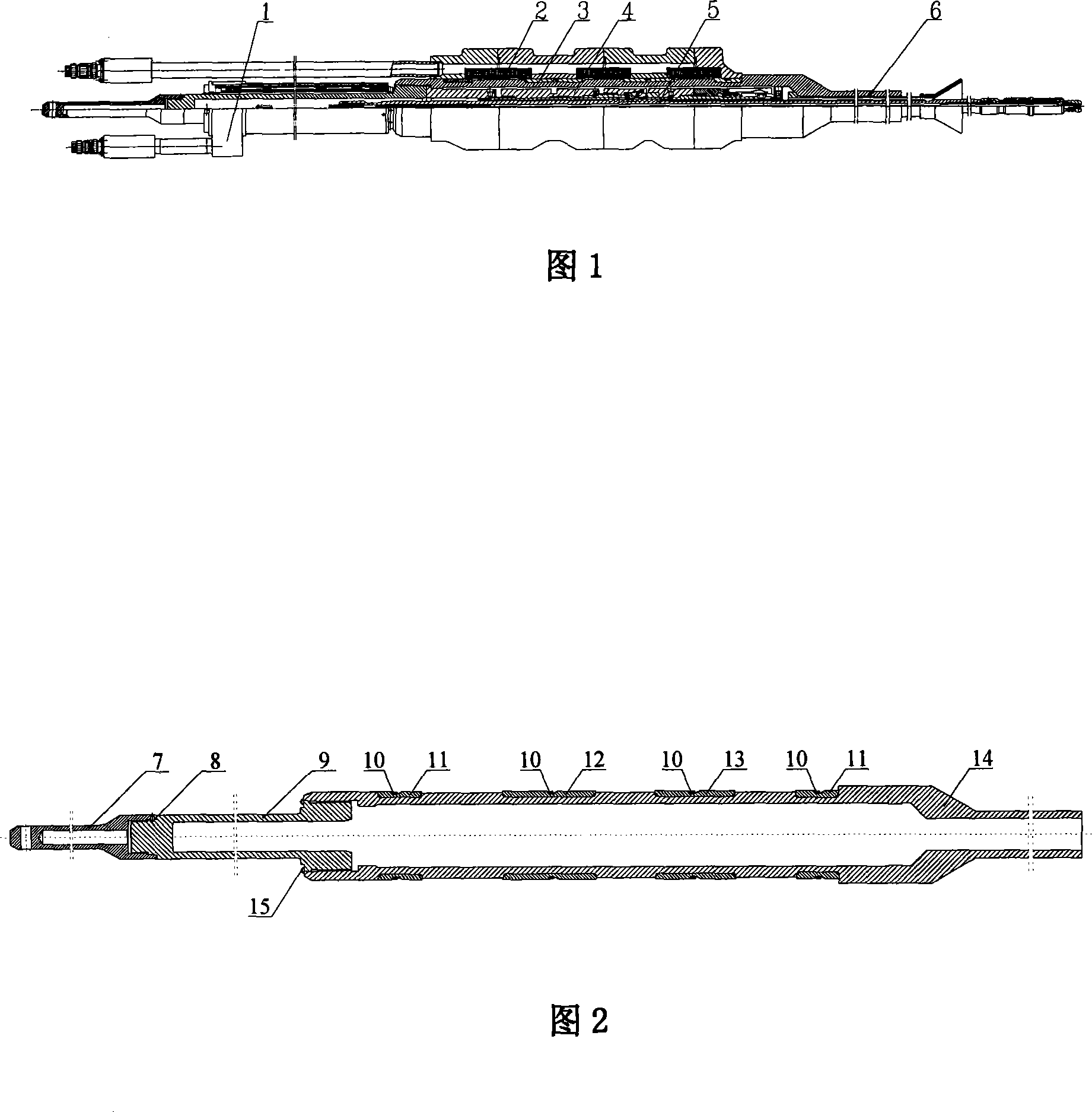

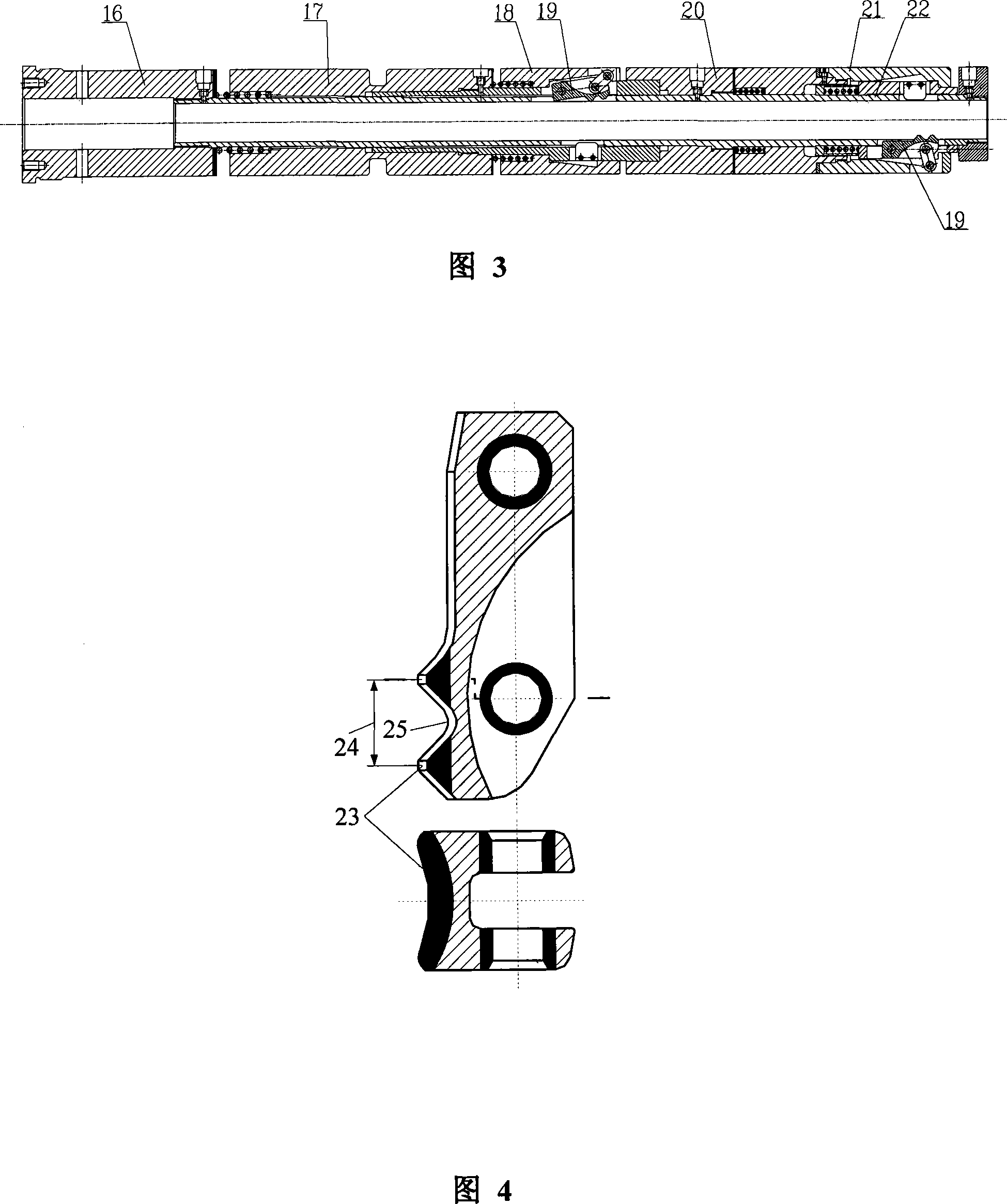

[0025] As shown in Figure 1, the step-by-step magnetic lifting type reactor control rod drive mechanism of the present invention consists of a rod position detector assembly 1, a coil assembly 2, a pressure shell assembly 3, a claw assembly 4, a drive rod assembly 5 and a heat insulation The set consists of 6 components. The whole mechanism is directly installed vertically on the top cover of the reactor pressure vessel. The rod position detector assembly 1 is set on the stroke sleeve 9 of the pressure-resistant shell assembly 3. When the driving mechanism is running, it can give the actual position signal of the driving rod. Rod time; the coil assembly 2 is set outside the sealing shell 14 of the pressure shell assembly 3, and the electromagnetic attraction generated by it provides a power source for the operation of the drive mechanism; the claw assembly 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com