Production of fine-grained particles

A particle and particle technology, applied in the field of particle manufacturing, can solve problems such as long reaction time and difficulty in obtaining crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] Example 1-CeO 2 the manufacture of

[0125] Manufacturing CeO 2 to introduce the method of the present invention. Use the following steps:

[0126] Step 1: Prepare a cerium nitrate solution containing 2.5 moles / liter of cerium nitrate.

[0127] Step 2: Heat 16 grams of Brij56 surfactant and 20 mL of cerium nitrate solution to -80°C. Surfactants are liquid at this temperature. The solution was slowly stirred and added to the surfactant liquid to produce a micellar liquid.

[0128] Step 3: Cool the micellar liquid to room temperature. The solution turned into a clear gel during cooling.

[0129] Step 4: The gel is heat treated according to the temperature and pressure history presented in FIG. 4 . In this example, an extended drying stage was used at 83°C prior to further heating.

[0130] The resulting CeO 2 Powder 1~253m 2 / g of surface area and contains particles with diameters ranging from ~2 to 8 nm. Transmission electron microscopy (TEM) suggested that the...

Embodiment 2

[0134] Manufactured CeO 2 and others containing cerium and one or more samarium copper and zirconium Ce 0.6 Sm 0.4 O x , Ce 0.65 Sm 0.2 Cu 0.15 O x , with Ce 0.6 Zr 0.2 Sm 0.1 Cu 0.1 O x of mixed oxides. x represents the oxygen content, since its exact content is composition-dependent and cannot be known precisely at this stage. These materials are excellent candidates for catalyst applications and can also be used in SOFC anodes. They are also a very useful test of the ability of the invention to make multi-component oxides. If the different metal compositions are uniformly distributed throughout the material, all these compositions should exhibit CeO 2 basic crystal structure. This is because additional elements can be incorporated into CeO 2 Crystal structure. However, uneven distribution of elements may result in pockets of material that may have a relatively high concentration of one or more particular elements. Such pockets can form different crystal st...

Embodiment 3

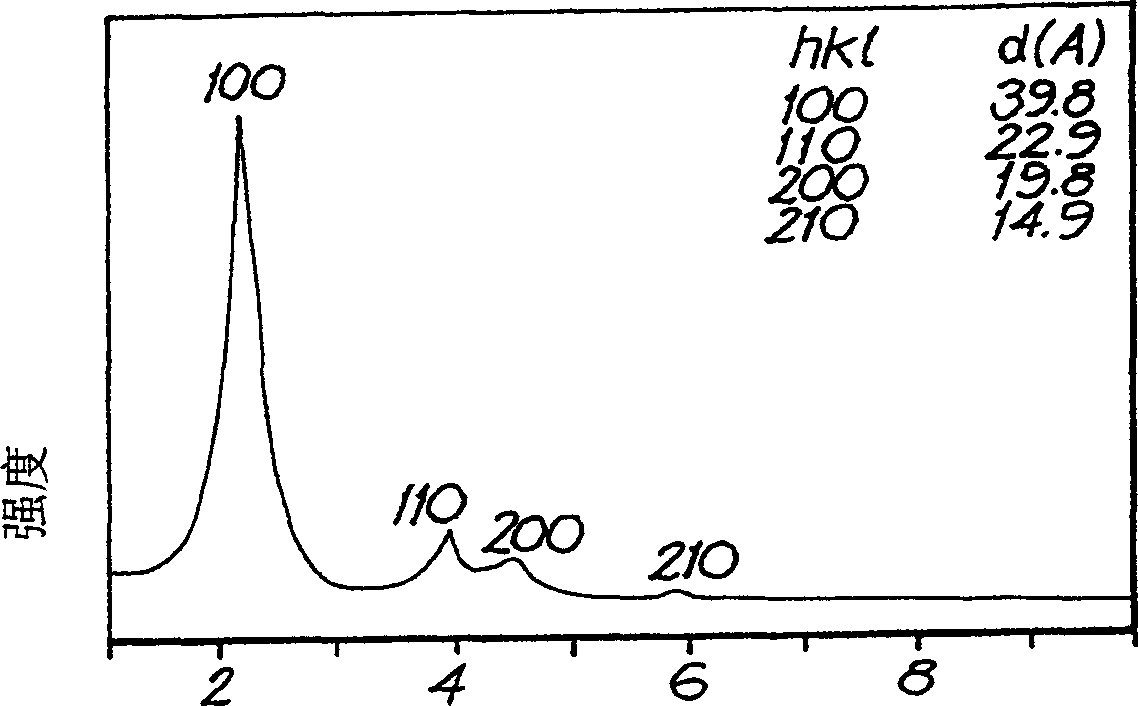

[0141] Example 3: La 0.6 Ca 0.2 Nd 0.2 Mn 0.9 Ni 0.1 O 3 the manufacture of

[0142] In solid oxide fuel cells, La 0.6 Ca 0.2 Nd 0.2 Mn 0.9 Ni 0.1 O 3 As a cathode material, the target "lanthanum manganate" crystal structure is also an excellent test material for the present invention because it is extremely sensitive to chemical composition. Even small changes in composition can lead to the formation of different crystalline structures. Therefore, the five different metal elements need to be uniformly distributed on an extremely fine scale to produce small particles with the correct crystalline structure.

[0143] Using co-precipitation and other traditional processes, previous researchers have encountered considerable difficulty in obtaining the correct crystalline structure because of its sensitivity to composition. In earlier techniques, careful co-precipitation followed by a prolonged (10-48 h) heat treatment at high temperature (800°C-1000°C) was required to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com