Preparation method of carbonyl nickel, nickel powder and its usage

A technology of nickel source and product, applied in the field of producing nickel carbonyl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

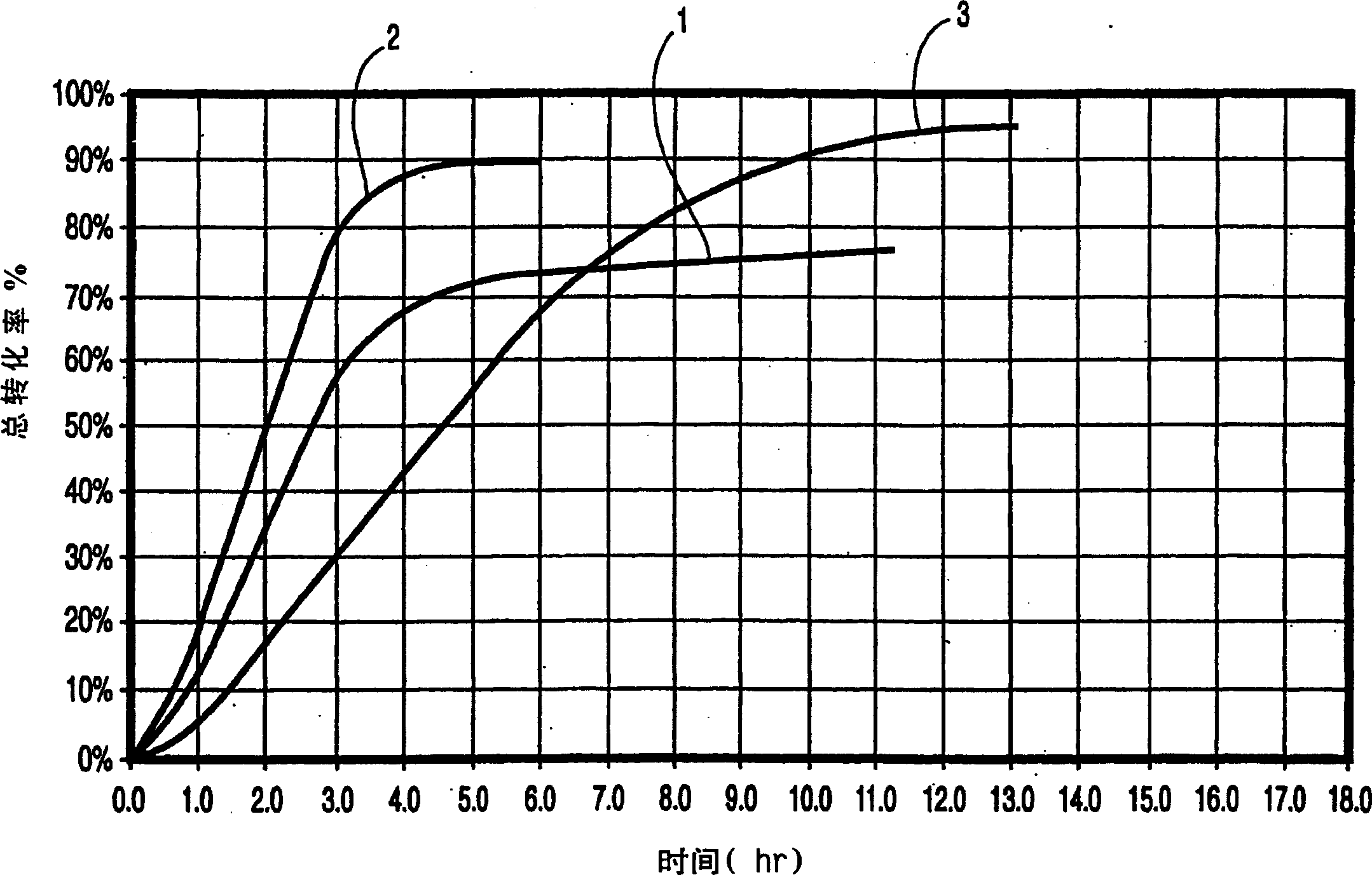

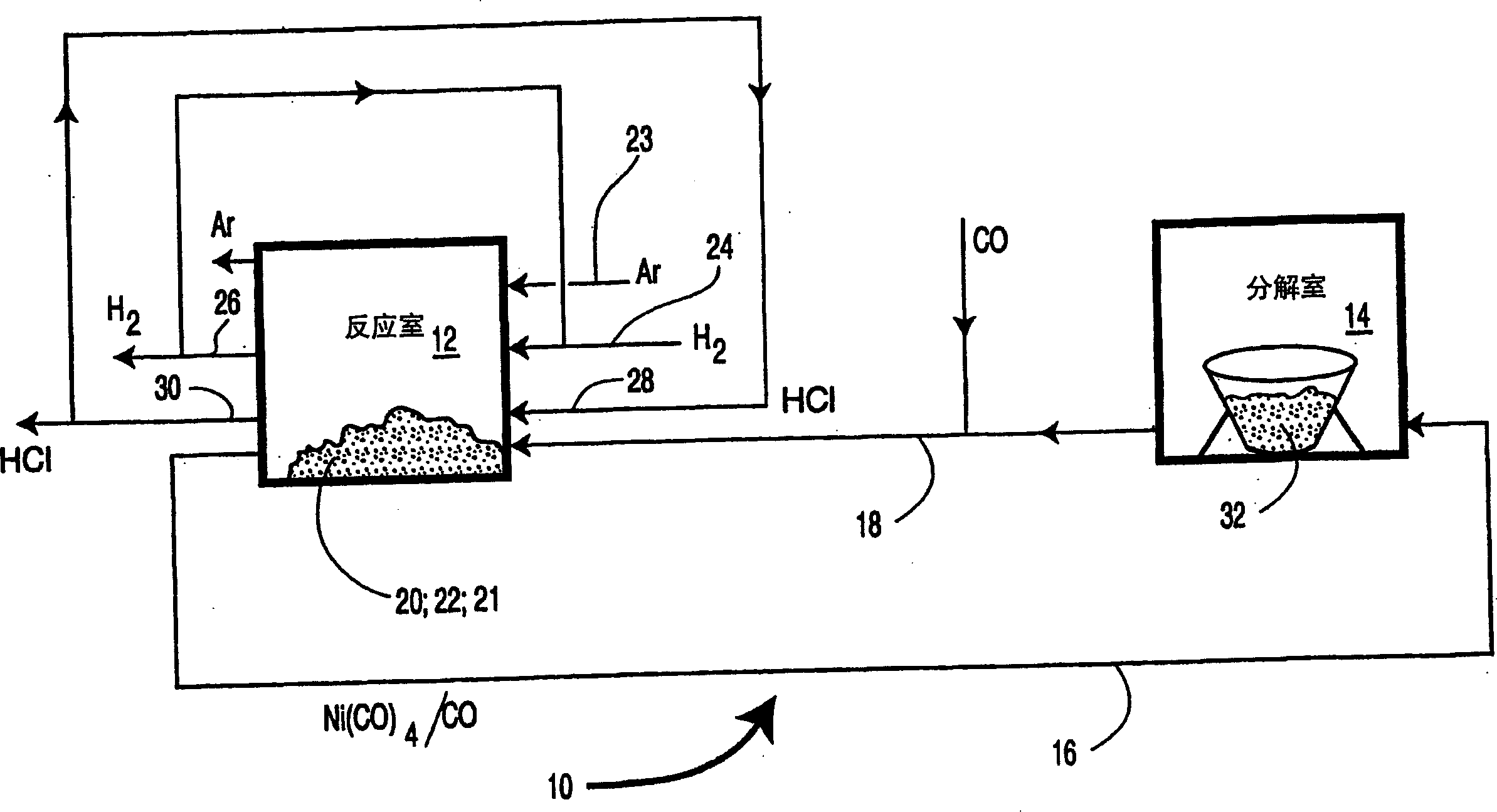

[0046] Embodiment 1 (prior art)

[0047] NiCO 3 powder (200g) into the extraction reactor, and then use H 2 The gas stream was treated at 500°C for 7 hours at a flow rate of 300 mL / min for essentially complete reduction. Cool the produced nickel powder to 100°C, then replace H with carbon monoxide 2 atmosphere. The reactor was further cooled to 50° C. and bubbled with CO gas at a flow rate of 300 mL / min. The resulting Ni(CO) 4 Nickel (10 g, 10% yield) was recovered as nickel powder after 12 hours by passing through a pair of carbonyl decomposers according to the prior art.

Embodiment 2

[0048] Embodiment 2 (prior art)

[0049] Ni(OH) 2 powder (100g) into the extraction reactor, and then 2 The gas stream was treated at 500°C for 7 hours at a flow rate of 300 mL / min for essentially complete reduction. The resulting nickel powder was placed in H 2 Cool to 100°C in atmosphere, then replace H with carbon monoxide 2 atmosphere. The reactor was further cooled to 50° C. and bubbled with CO gas at a flow rate of 300 mL / min. The resulting Ni(CO) 4 The gas was passed to the carbonyl decomposer and nickel (6 g, 9.5% yield) was recovered as nickel powder after 12 hours.

Embodiment 3

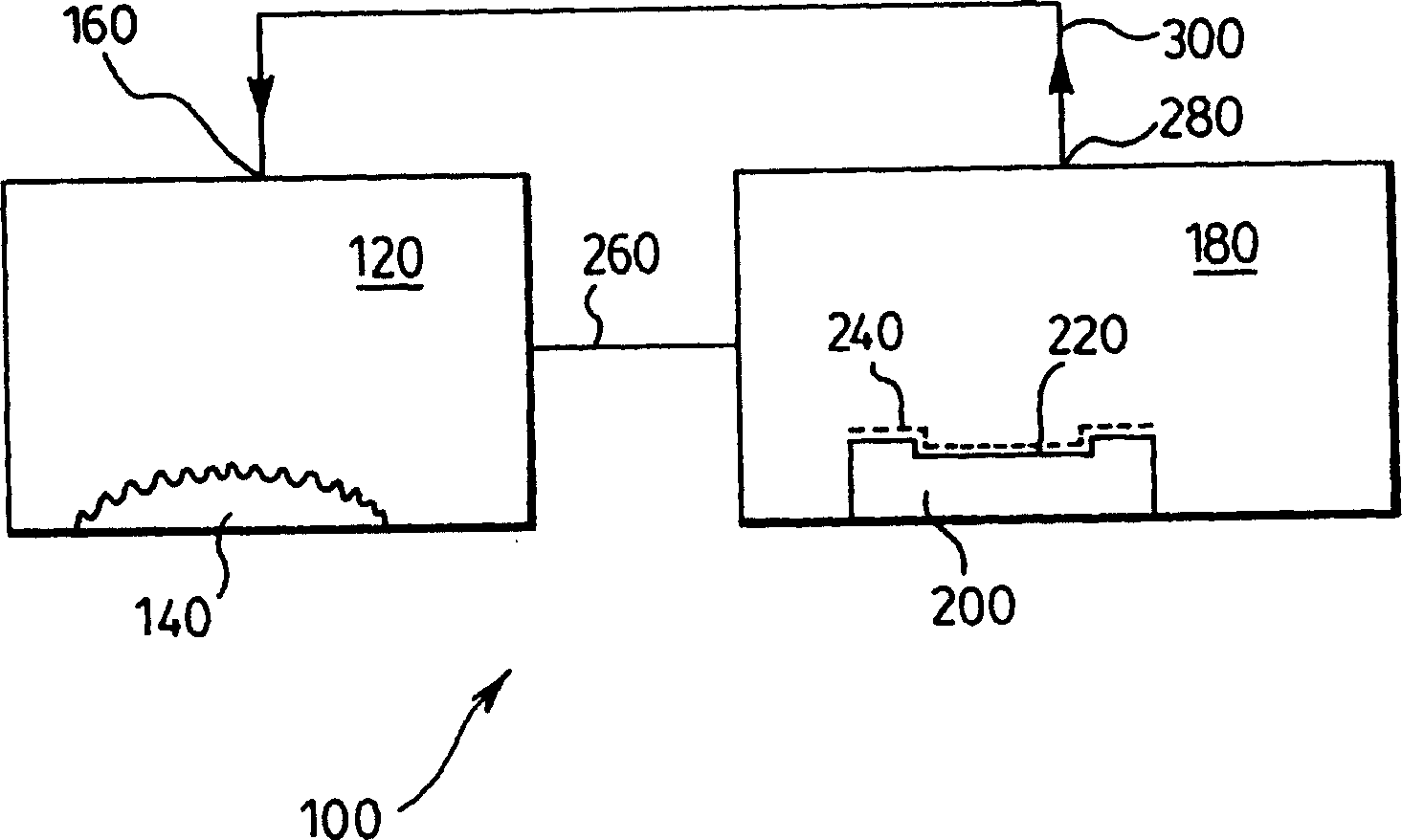

[0051] 300.1 g of nickel carbonate / nickel chloride mixture (10:1 w / w) was put into the extraction reactor, and treated with hydrogen (2 L / min) at 450° C. for 6 hours. Subsequently, the hydrogen was replaced with argon, the reactor was cooled to 40 °C and the argon was replaced with carbon monoxide at a gas temperature of 80 °C and a flow rate of 4 L / min, resulting in the formation of nickel carbonyl, which was collected and subsequently decomposed into Ni and CO at 6 103 g of nickel powder was provided within 1 hour, corresponding to a yield of 70% of the nickel extraction yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com