Continuous carbonylation reactor

A reactor and cylinder technology, applied in the field of continuous carbonylation reactors, can solve the problems of discontinuous carbonylation reaction and low efficiency, and achieve the effects of reduced product energy consumption, high efficiency, and enhanced airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

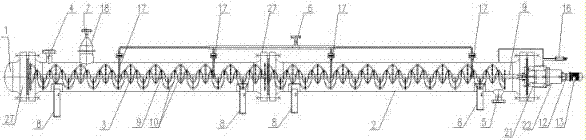

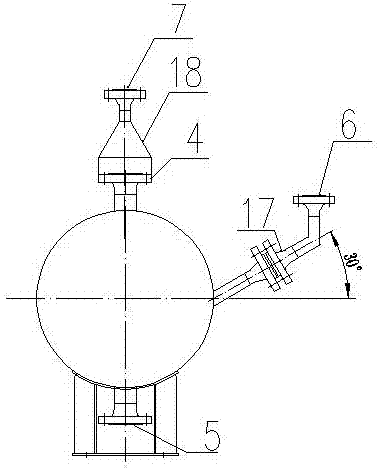

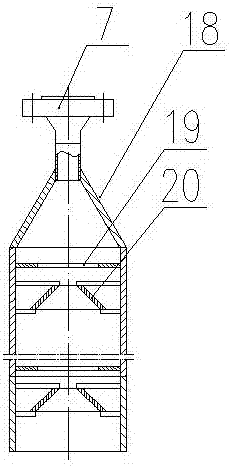

[0024] Such as Figure 1-6 As shown, a continuous carbonylation reactor includes a head 1, two cylinders 2 and a stirring propulsion device 3, the head 1 and the cylinder 2 are connected by a flange 27, and the cylinders 2 are connected by a flange 27 The cylinder body 2 is provided with a material inlet 4, a residue outlet 5, a gas inlet 6 and a gas outlet 7; the gas inlet 6 is connected to two gas sub-inlets 17 through a pipeline, and the gas sub-inlet 17 is connected to the cylinder body 2, and the gas sub-inlet 17 and The horizontal angle of the cylinder 2 is 30°; the end of the gas outlet 7 is provided with a gas settling chamber 18, and the gas settling chamber 18 is provided with an annular baffle 19 and a human-shaped baffle 20, and two saddle-shaped baffles are arranged under each cylinder 2. The support 8; the saddle suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com