Method for preparing cobalt clad beta-NiOOH by liquid phase oxidation method

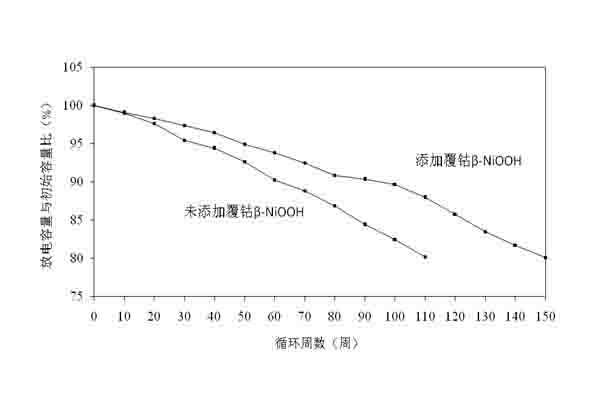

A liquid-phase oxidation method and cobalt-coated technology, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of irreversible electrodes, low conversion rate, and low conversion rate of β-NiOOH, so as to improve cycle life and discharge platform , the effect of easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Preparation of cobalt-coated β-NiOOH by liquid phase oxidation

[0017] At room temperature, dissolve 800g (20mol) NaOH in 2000g deionized water, add 1483g (16mol) cobalt-coated Ni(OH) 2 (commercially available, Co / Ni=5.4%) mixed and stirred, keeping the temperature at 25°C, adding 2143g (9mol) Na 2 S 2 o 8 , heat up to 60°C±5°C and keep warm, stir rapidly for 3h, then let the reaction solution stand for 0.5h, separate layers, remove the upper clear liquid, add 2000ml of water, continue stirring for 0.5h, stand still, separate layers, remove the supernatant , add 700ml of water in three times, wash and vacuumize, and dry the precipitate at 80°C for 2h to obtain the product.

[0018] The starting material is coated with cobalt Ni(OH) 2 And product is done ICP test and XRD pattern, the results are shown in Table 1 and figure 1 .

[0019] Table 1 Starting material cobalt-coated Ni(OH) 2 And the ICP (Co / Ni) results of the product

[0020]

...

Embodiment 2

[0023] Example 2 Preparation of cobalt-coated β-NiOOH by liquid phase oxidation

[0024] At room temperature, dissolve 800g (20mol) NaOH in 2000g deionized water, add 1330g (14mol) cobalt-coated Ni(OH) 2 (commercially available, Co / Ni=4.8%) mixed and stirred, keeping the temperature at 15°C, adding 1892g (7mol) K 2 S 2 o 8 , raise the temperature to 45°C±5°C and keep it warm, stir rapidly for 2h, then let the reaction solution stand for 1h, separate layers, remove the clear liquid in the upper layer, add 1000ml of water, continue stirring for 0.5h, stand still, separate layers, remove the supernatant, Add 400ml of water in three times, wash and vacuumize, and dry the precipitate at 80°C for 2h to obtain the product.

[0025] The starting material is coated with cobalt Ni(OH) 2 And the product is tested by ICP, the result shows that Co / Ni=4.8% in the product, which is the same as the starting material coated with cobalt Ni(OH) 2 The Co / Ni are the same, and the product is d...

Embodiment 3

[0027] Example 3 Preparation of cobalt-coated β-NiOOH by liquid phase oxidation

[0028] At room temperature, dissolve 800g (20mol) NaOH in 2000g deionized water, add 1854g (20mol) cobalt-coated Ni(OH) 2 (commercially available, Co / Ni=6.0%) mixed and stirred, keeping the temperature at 45°C, adding 2857g (12mol) Na 2 S 2 o 8 , raise the temperature to 80°C±5°C and keep it warm, stir rapidly for 1h, then let the reaction solution stand for 0.5h, separate layers, remove the upper clear liquid, add 3000ml of water, continue stirring for 0.5h, stand still, separate layers, remove the supernatant , add water for a total of 950ml three times, wash and vacuumize, and dry the precipitate at 80°C for 2h to obtain the product.

[0029] The starting material is coated with cobalt Ni(OH) 2 And the product is tested by ICP, the result shows that Co / Ni=6.0% in the product, which is the same as the starting material coated with cobalt Ni(OH) 2 The Co / Ni are the same, so it is determine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com